A kind of decalcification method of electrolytic manganese dioxide

A technology of electrolytic manganese dioxide and electrolyte, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of incomplete precipitation process, difficulty in removing calcium ions, and inability to meet the demand for high-quality electrolyte, and achieve a suitable large-scale Large-scale production, low mechanical equipment requirements, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

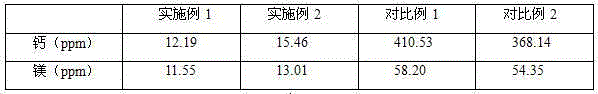

Examples

Embodiment 1

[0022] (1) Put the high-calcium electrolytic manganese dioxide powder into the electrolyte, the molar ratio of sulfuric acid and manganese sulfate in the electrolyte is 1:600, soak at 60°C for 60 minutes. Vacuum filtration, control the pH value below 3.0;

[0023] (2) Dry in an oven at a temperature of 110°C. The time is 120 minutes. Slurry with water;

[0024] (3) Neutralization: add 1mol / L sodium hydroxide, adjust the pH value to 5.5, control the temperature at 60°C, and last for 60 minutes;

[0025] (4) Dry in an oven at a temperature of 110°C. The time is 120 minutes.

Embodiment 2

[0027] (1) Put the high-calcium electrolytic manganese dioxide powder into the electrolyte, the molar ratio of sulfuric acid and manganese sulfate in the electrolyte is 2:1, soak at 40°C for 100 minutes. Vacuum filtration, control the pH value below 4.5;

[0028] (2) Dry in an oven at 60°C. The time is 180 minutes. Slurry with aqueous solution;

[0029] (3) Neutralization: add 0.5mol / L sodium hydroxide, adjust the pH value to 5.0, control the temperature at 70°C, and last for 30 minutes;

[0030] (4) Dry in an oven at a temperature of 120°C. The time is 60 minutes.

Embodiment 3

[0032] (1) Put the high-calcium electrolytic manganese dioxide powder into the electrolyte, the molar ratio of sulfuric acid and manganese sulfate in the electrolyte is 1:450000, soak at a temperature of 75°C for 30 minutes. Vacuum filtration, control the pH value below 3.0.

[0033] (2) Dry in an oven at a temperature of 120°C. The time is 120 minutes. Slurry with aqueous solution;

[0034] (3) Neutralization: add 3mol / L sodium hydroxide, adjust the pH value to 5.8, control the temperature at 40°C, and last for 100 minutes;

[0035] (4) Dry in an oven at a temperature of 90°C. The time is 180 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com