Light porous wave absorbing film and preparing method thereof

A light-weight wave-absorbing film technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of high surface density, insufficient bending, and high thickness of wave-absorbing films, and achieve low cost, uniform distribution, and fewer processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

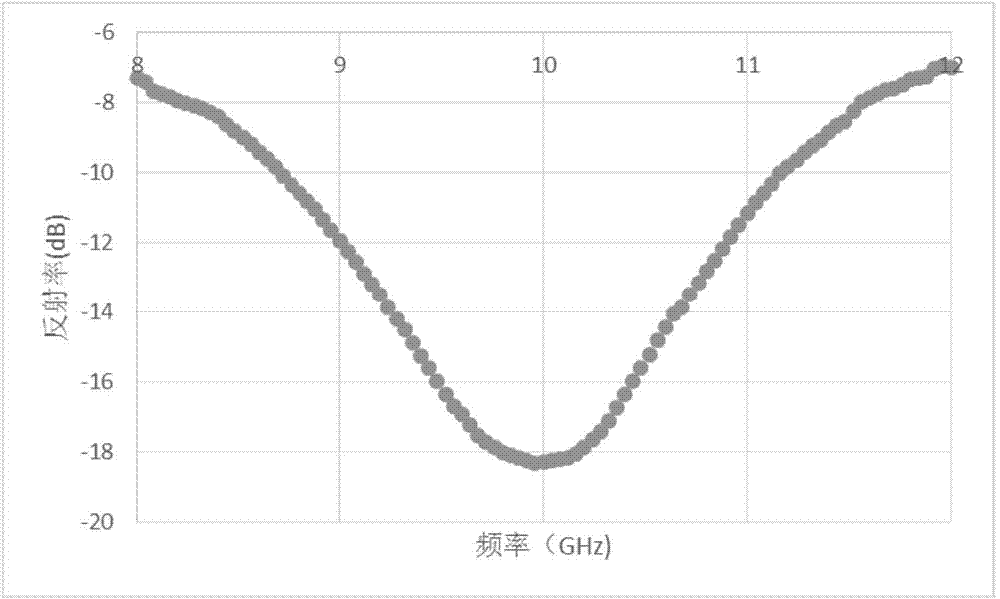

[0037] The mass ratio of Fe-Si-Al powder to nanocellulose is 75:25, and the surface density of the prepared wave-absorbing film is 0.4kg / m 2 . The nanocellulose is fully stirred and dispersed in isopropanol, and the volume ratio of the nanocellulose mass to the used isopropanol is 1 mg / ml; the wave-absorbing material is added to the dispersed nanocellulose solution, and the second stirring is carried out to To achieve overall homogenization; then transfer to the filter for vacuum filtration; after the filtration is completed, place it under normal temperature and pressure conditions to allow the residual isopropanol inside the membrane to volatilize naturally. The absorbing membrane can be easily transferred from the filter membrane after drying. The wave absorption test curve of the obtained lightweight wave-absorbing film is as follows figure 1 shown. After testing, it can effectively absorb electromagnetic waves with a frequency of 8--12GHz, and its porosity is 50%. The...

example 2

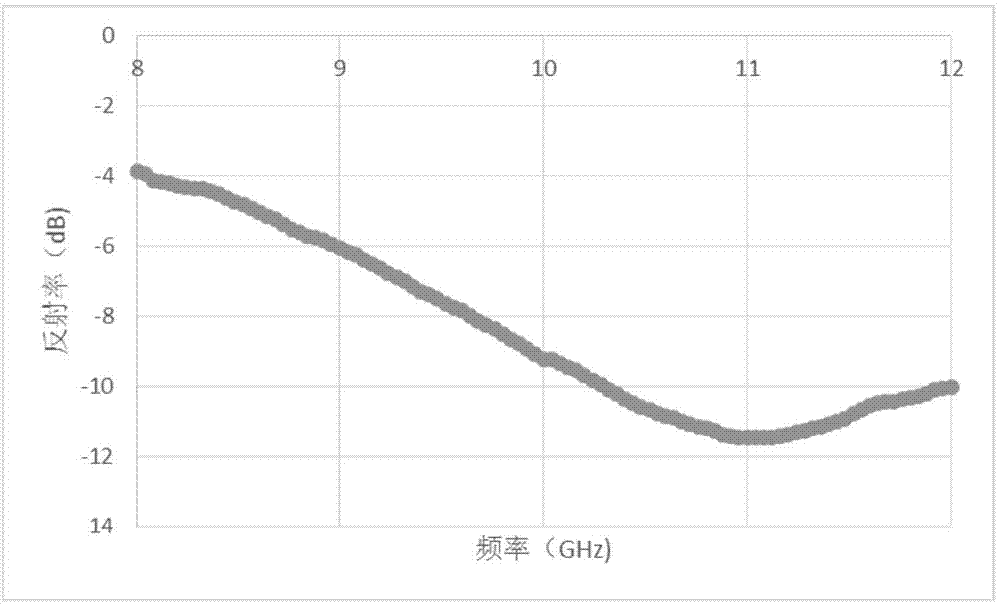

[0039] The mass ratio of Fe-Si-Al powder to fibrillated polyethylene fiber is 90:10, and the surface density of the prepared wave-absorbing film is 0.8kg / m 2 , the fibrillated polyethylene fiber is fully stirred and dispersed in absolute ethanol, and the volume ratio of the quality of the fibrillated polyethylene fiber to the isopropanol used is 1mg / ml; In the vinyl fiber solution, carry out secondary stirring to achieve overall homogenization; then transfer it to a filter for high-pressure filtration; place it in a vacuum oven at 120°C for drying after completion of pressure filtration. The absorbing membrane can be easily transferred from the filter membrane after drying. After testing, it can effectively absorb electromagnetic waves with a frequency of 6--14GHz, its porosity is 50%, and the surface density of the absorber is lower than 2kg / m 2 . The tensile strength reaches 7MPa.

example 3

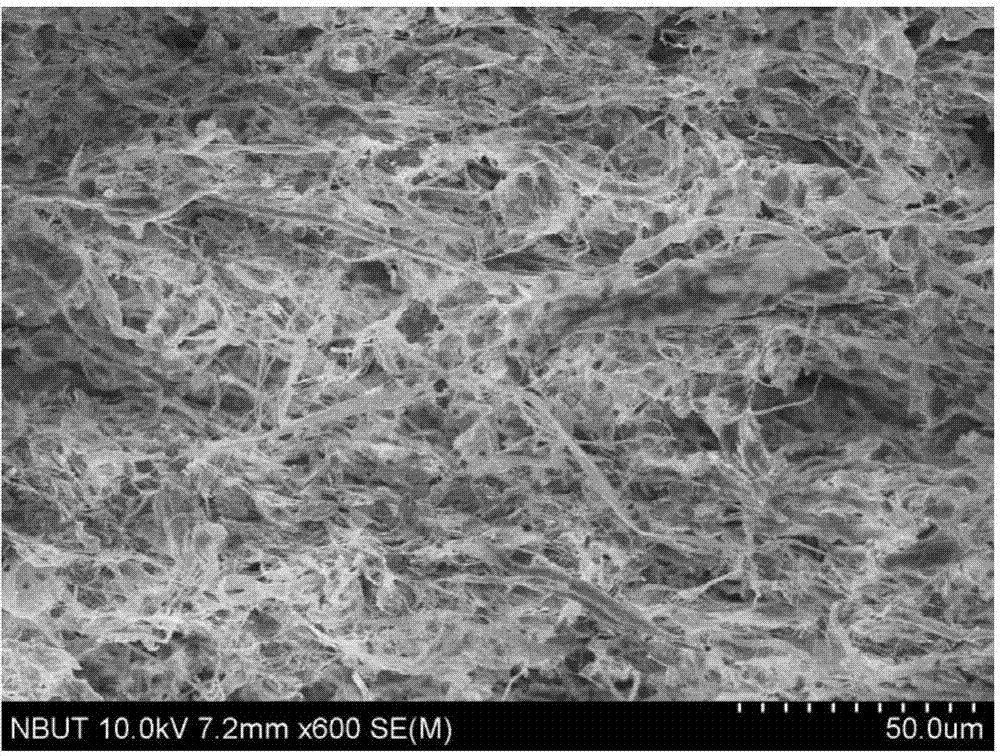

[0041] The mass ratio of Fe-Si-Al powder to nanocellulose and fibrillated polyethylene fiber is 75:15:10, and the surface density of the prepared wave-absorbing film is 1.6kg / m 2 , the nanocellulose and fibrillated polyethylene fibers are fully stirred and dispersed in water, and the volume ratio of the nanocellulose and fibrillated polyethylene to the isopropanol used is 0.25 mg / ml respectively; wave absorbing agent is added to disperse In the good nanocellulose and fibrillated polyethylene fiber solution, carry out secondary stirring to achieve overall homogenization; then transfer to the filter for vacuum filtration; filter the initial product and place it under normal temperature and pressure conditions, so that the membrane body The isopropanol remaining inside will evaporate naturally. The absorber membrane can be easily transferred from the filter membrane after drying. The cross-sectional electron microscope image of the obtained wave-absorbing film is shown in imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com