Pressure-sensitive adhesive with anti-dazzle function

A pressure-sensitive adhesive and anti-glare technology, applied in the direction of adhesive types, ester copolymer adhesives, polymer adhesive additives, etc., can solve the problems of bottlenecks in the roughness of the matte surface, and achieve improved roughness, Improve high temperature resistance and avoid cluster effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

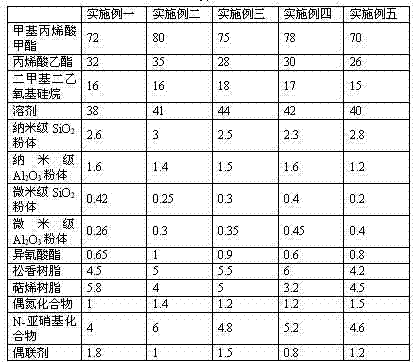

[0027] Embodiments 1 to 5: a pressure-sensitive adhesive with anti-glare function, the pressure-sensitive adhesive is composed of the following components by weight:

[0028] 75~78 parts of methyl methacrylate,

[0029] 30~32 parts of ethyl acrylate,

[0030] Dimethyldiethoxysilane 16~18 parts,

[0031] 40~45 parts of solvent,

[0032] Nanoscale SiO 2 Powder 2.2~2.8 parts,

[0033] Nanoscale Al 2 o 3 Powder 1.2~1.8 parts,

[0034] Micron SiO 2 Powder 0.2~0.5 parts,

[0035] Micron Al 2 o 3 Powder 0.2~0.5 parts,

[0036] 0.8~1 part of isocyanate,

[0037] Rosin resin 4.5~5 parts,

[0038] Terpene resin 4~5 parts,

[0039] Azo compound 1.2~1.5 parts,

[0040] 4.5~5 parts of N-nitroso compounds,

[0041] 1~1.5 parts of coupling agent;

[0042] The chemical formula of the coupling agent is: CH 2 =CH-Si(OC 2 h 5 ) 3 .

[0043] The above nano-SiO 2 The average diameter of the powder is 12nm, and the nano-Al 2 o 3 The average size of the powder so far is 30 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com