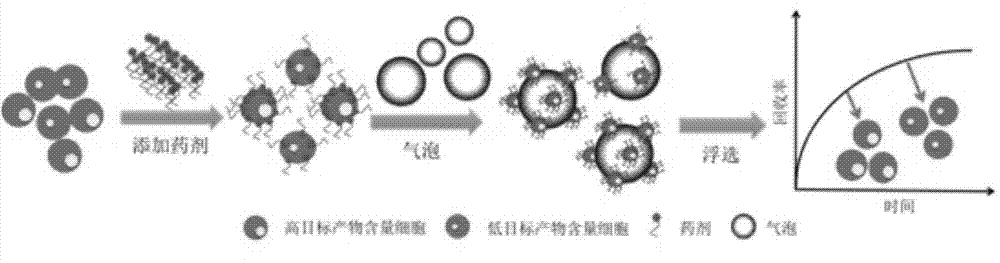

Method for sorting microalgae at high throughput

A high-throughput, microalgae technology, applied in unicellular algae and other directions, to achieve the effects of less cell damage, low cost, and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Algae species: select Chlorella, isolated from the freshwater waters of southern Xinjiang;

[0028] 2. Synchronized culture: 250mL Erlenmeyer flask was inoculated with 150mL culture solution in shake flask culture, the initial inoculation concentration was 1×10 6 Cells / mL, 14h / 10h light and dark cycle culture Chlorella to achieve synchronized culture. The reactor used is an open or closed reactor; the light source used is sunlight, incandescent lamp, LED lamp, etc.; the cultivation method is autotrophic cultivation.

[0029] 3. Selective hydrophobization in batches: the microalgae cells in the logarithmic phase, stable phase and recession phase were taken to measure the oil content after cultured to the 5th day, 10th day and 15th day, and the oil content of each stage was 33%, 38%, and 43% respectively . Take microalgae cells to adjust the concentration of algae liquid to 1g / L, and add 0.005, 0.01, 0.03, 0.05g / LAl to 100mL of cells at each stage 2 (SO 4 ) 3 18H ...

Embodiment 2

[0031] Embodiment 2 (all the other steps are with embodiment 1)

[0032] 1. Microalgae culture: use 0.6m under natural light 2 Culture Chlorella in plastic pots for 10 days to obtain heterogeneous cells with an average oil content of 35%;

[0033] 2. Pre-hydrophobic treatment: add 0.01g / L Al 2 (SO 4 ) 3 18H 2 O, stir rapidly for 2min;

[0034] 3. Flotation: Harvest the microalgae biomass that floats out within 0 to 2 minutes by dissolved air flotation. The biomass accounts for 1 / 3 of the total biomass, and the oil content of the biomass reaches 39%.

Embodiment 3

[0035] Embodiment 3 (all the other steps are with embodiment 1)

[0036] 1. Microalgae culture: use 0.6m under natural light 2 Chlorella was cultured in plastic pots for 7 days to obtain heterogeneous cells with an average oil content of 26%.

[0037] 2. Pre-hydrophobic treatment: add 0.01g / L Al 2 (SO 4 ) 3 18H 2 O, stir rapidly for 2min.

[0038] 3. Flotation: Harvest the microalgae biomass that floats out within 0 to 2 minutes by dissolved air flotation. The biomass accounts for 1 / 3 of the total biomass, and the oil content of the biomass reaches 36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com