Shock-resistant steel-bar concrete structure side coal bunker

A technology of concrete structure and steel reinforced concrete, which is applied in earthquake resistance, building components, building structure, etc., can solve the problems of high construction cost and many fire prevention, and achieve the effect of reducing construction cost, saving steel and reducing foundation load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

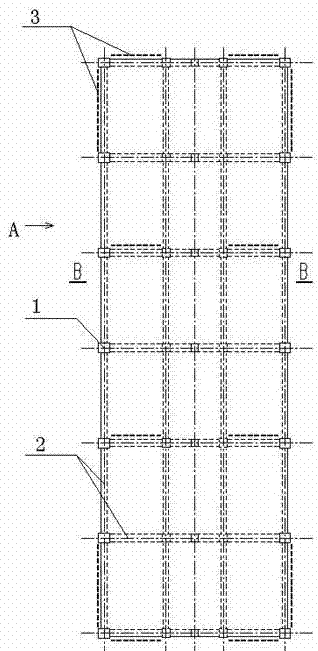

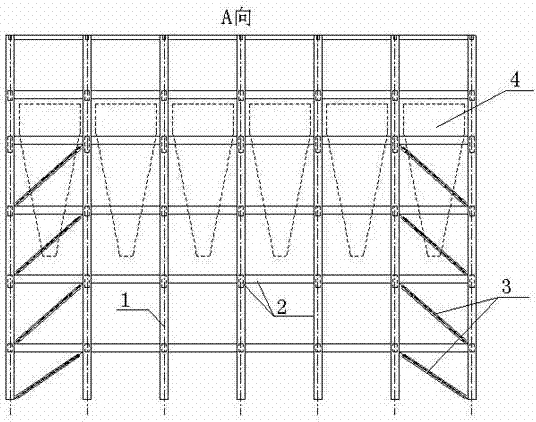

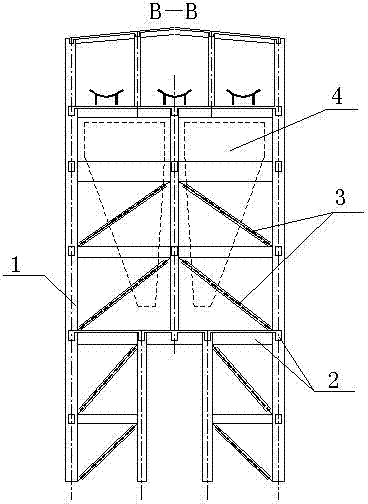

[0024] refer to figure 1 , Figure 4 , Figure 5 , the present invention comprises frame column 1, frame beam 2, frame column 1 is made of frame column steel bar 101, frame column steel bar 102, frame column concrete inner core 103, frame beam 2 is made of frame beam steel bar 201, frame beam bar 202, The frame beam concrete inner core 203 is composed of frame columns and frame beams with steel frames respectively to form frame column steel frames and frame beam steel frames. The frame column steel frames and frame beam steel frames are connected to form a steel skeleton. The steel frame of the column and the steel frame of the frame beam are respectively bound to the steel bar of the frame column and the steel bar of the frame beam. The concrete frame is provided with buckling restraint supports 3 horizontally and vertically.

[0025] refer to figure 1 , figure 2 , image 3 , the buckling restraint support 3 is longitudinally arranged in the unit frame below the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com