Slurry shield main engine for upper-soft lower-hard ground

A mud-water shield and hard formation technology, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve problems such as short tool life, difficult ground settlement control, and low excavation efficiency, so as to solve cutting problems, improve construction efficiency and Reliability and the effect of improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A muddy water shield main engine that can be used in upper soft and lower hard formations, including a compound cutter head, a main drive and a shield body arranged at the front end, the rear part of the compound cutter head is fixedly connected with the main drive, and the main drive is installed on the shield body. The back of the composite cutter head is provided with a tapered box, the middle part of the shield is provided with a central hopper, and the bottom of the shield is provided with a bottom slurry suction pipe; the rear end of the central hopper is provided with a central slurry suction pipe; the bottom slurry suction pipe The front end is provided with a grille matched with the conical box.

[0022] The composite cutter head cuts the entire soil layer on the face of the front end, and a part of the cut rock and soil enters the central hopper through the composite cutter head, and then is transported to the tail of the shield body through the central slurry ...

Embodiment 2

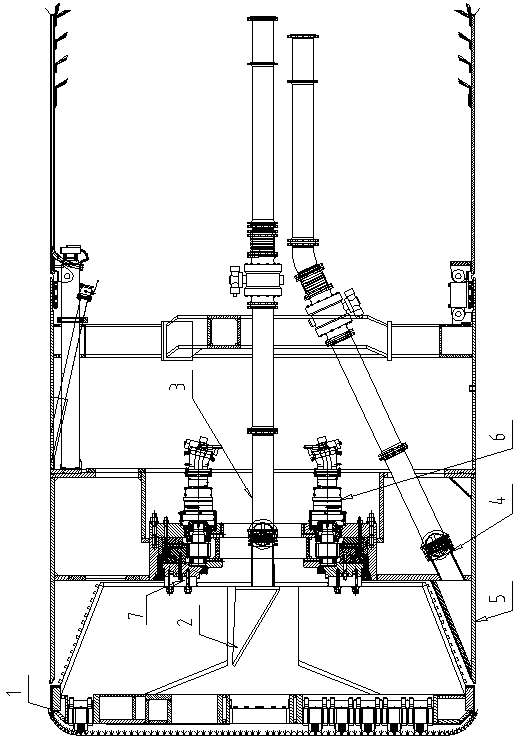

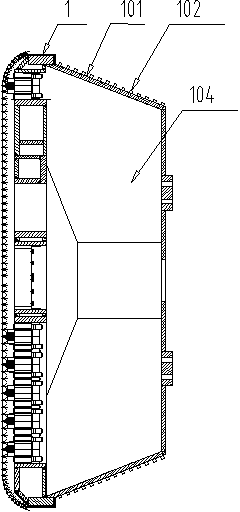

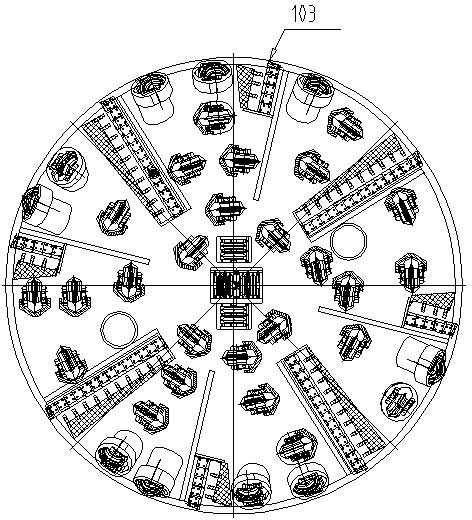

[0025] A kind of mud-water shield main engine that can be used in upper soft and lower hard formations, such as figure 1 As shown, it includes a compound cutter head 1, a main drive 6 and a shield body 5. The shield body 5 supports the entire device, and the composite cutter head 1 is arranged at the front end of the shield body 5 . The compound cutter head 1 is arranged at the front end of the whole device, and directly contacts with the face of the face. The main drive 6 is installed on the shield body 5, the rear part of the compound cutter head 1 is bolted to the main drive 6 through the flange 7, and the main drive 6 is fixed on the shield body 5 by bolts. The effect of main drive 6 is mainly to drive the rotation of compound cutter head 1 . The main drive 6 can rotate forward and reverse, so that the composite cutterhead 1 has the function of forward and reverse rotation, thereby preventing rock blocks from accumulating on one side of the composite cutterhead 1 and the...

Embodiment 3

[0035]A muddy water shield main engine that can be used in upper soft and lower hard formations, including a compound cutter head, a main drive and a shield body arranged at the front end, the rear part of the compound cutter head is fixedly connected with the main drive, and the main drive is installed on the shield body. The back of the composite cutter head is provided with a tapered box, the middle part of the shield is provided with a central hopper, and the bottom of the shield is provided with a bottom slurry suction pipe; the rear end of the central hopper is provided with a central slurry suction pipe; the bottom slurry suction pipe The front end is provided with a grille matched with the conical box.

[0036] The conical box body is a whole, and the conical surface is provided with fragment holes, and the two sides of the fragment holes are provided with wear-resistant blocks. The fragment holes are evenly distributed on the conical surface of the conical box, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com