Direct absorption solar heat collector based on secondary reflection concentrating system

A solar heat collection and light concentration system technology, applied in the field of direct heat absorption solar heat collection devices, can solve the problem of lack of flow regulation and working fluid temperature control functions, unfavorable environmental protection and operation safety, and inaccurate control of molten salt temperature, etc. problems, to achieve the effects of not being prone to local thermal failure, high safety, and not being blocked by molten salt freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

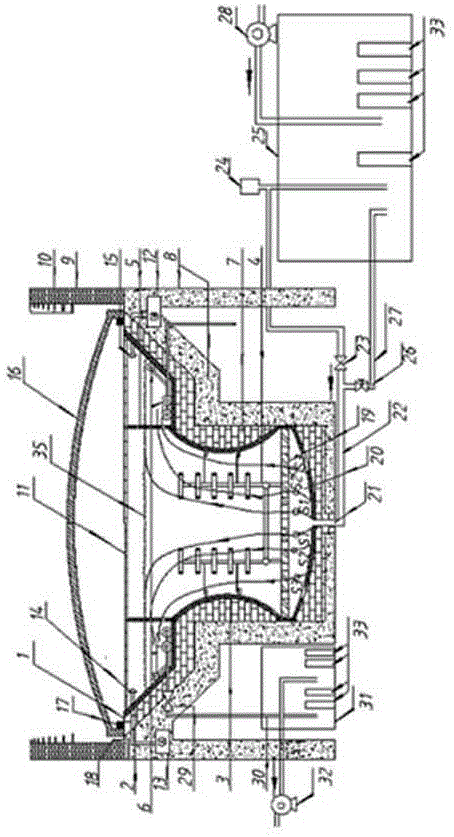

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, wherein the schematic embodiments and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

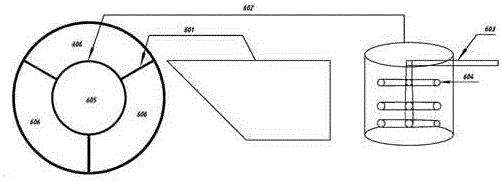

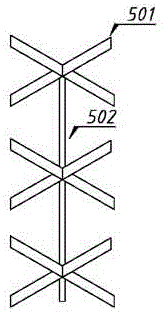

[0041] Such as Figure 1-9 As shown, a direct heat-absorbing solar heat collection device based on a secondary reflection concentrating system includes an upper round table 1, a heat-absorbing cavity, a high-temperature molten salt buffer tank 31 and a low-temperature molten salt storage tank 25, and the upper part There are multiple partition plates 5 in the cavity of the round table 1. There are high-temperature molten salt outlet devices 6 on the inner wall and bottom of the upper round table 1. The high-temperature molten salt outlet device 6 is connected to the high-temperature molten salt buffer tank 31 through the high-temperature molten salt outlet pipe 30. The upper round table 1 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com