The method of removing the residual gold of the lithography marking point of the LED chip

A technology of LED chip and lithography marking, which is applied to electrical components, electric solid devices, circuits, etc., can solve the problems that the metal of the LED chip should not be removed, and the residual gold of the lithography marking point of the LED chip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

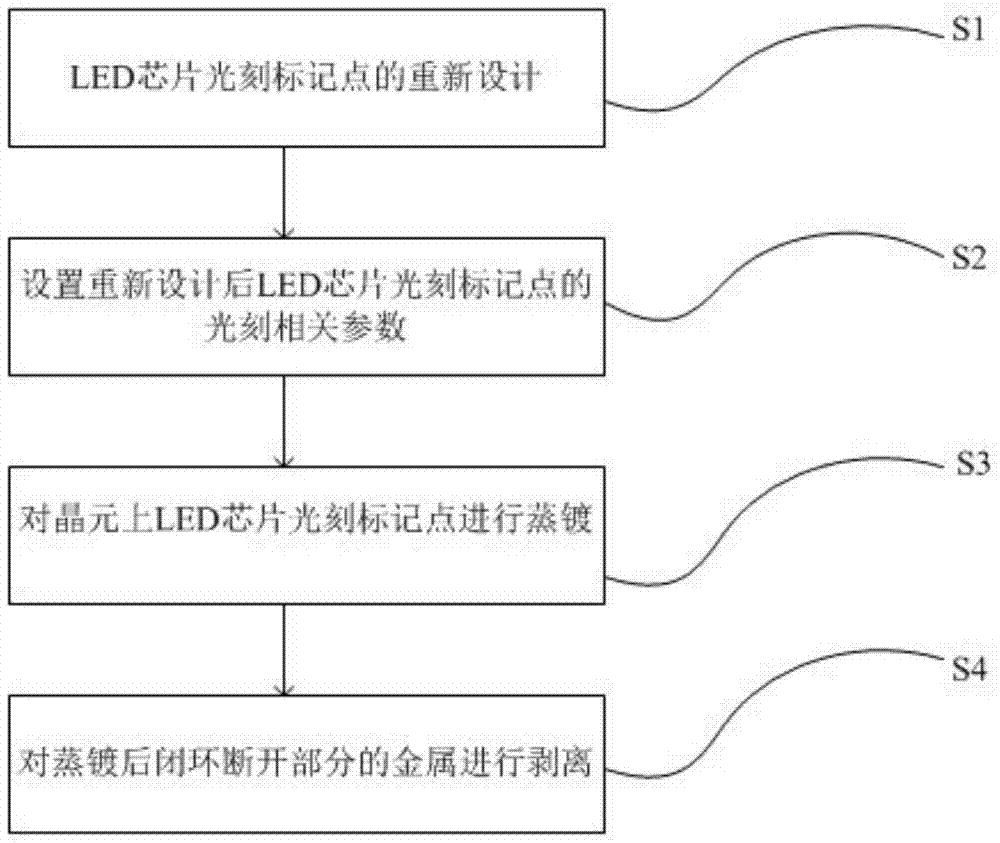

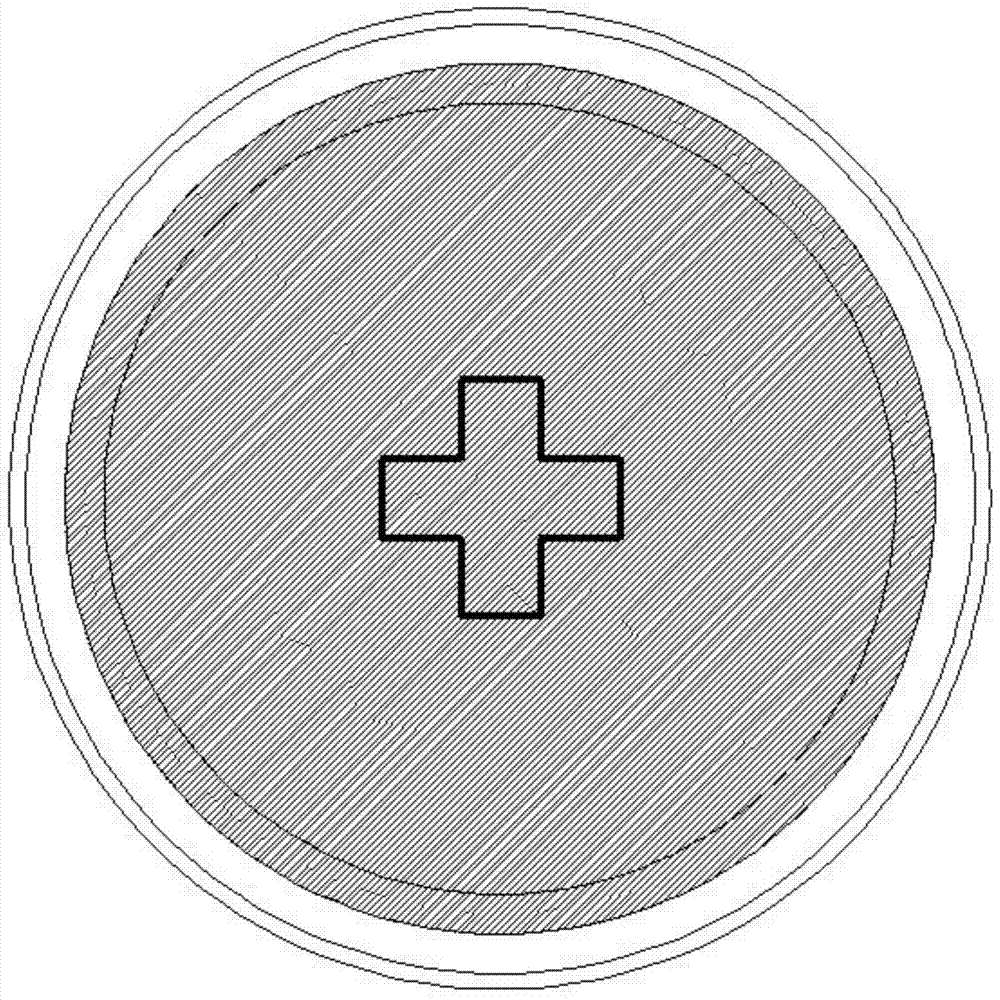

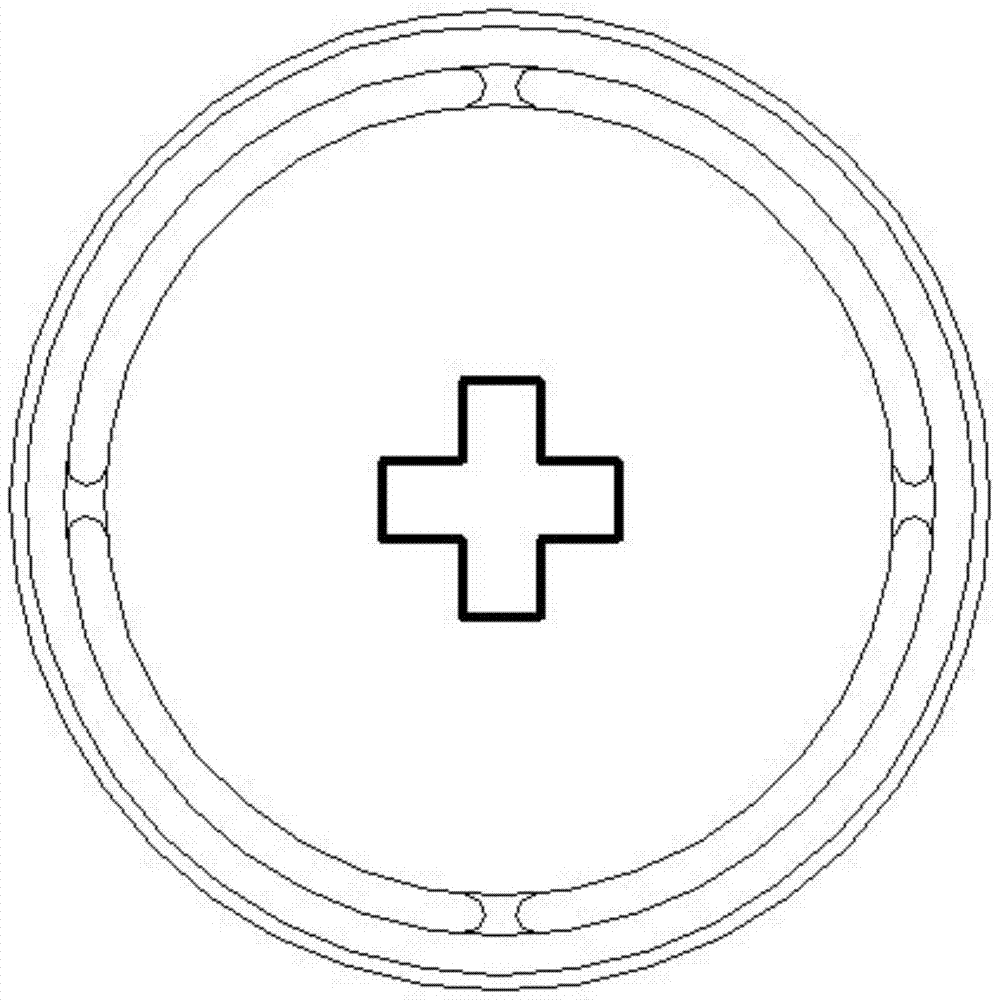

[0045] combine figure 2 with image 3 Describe the specific workflow, a method for removing residual gold at photolithographic marking points of LED chips, including redesigning the photolithographic marking points of LED chips, setting the width of the broken part of the ring to 15 μm, and fixing the opening direction of the broken part of the ring. The angle range is 45°, the fillet radius of the broken part of the ring is 7 μm, and the broken part of the ring adopts the method of large inside and small outside; set the lithography-related parameters of the lithography marking points of the LED chip after the redesign, and evenly The gel soft-baking temperature is 113°C, the exposure dose is 60mJ, the PEB temperature is 106°C, and the development time is 100s, then stand still. According to the parameters, the temperature of the photolithographic marking point of the LED chip is set for vapor deposition, and then the photolithographic marking point of the LED chip on the w...

Embodiment 2

[0047] combine Figure 4 with Figure 5 Describe the specific workflow, a method for removing residual gold from photolithographic marking points of LED chips, including redesigning the photolithographic marking points of LED chips, setting the width of the disconnected part of the square ring to 15 μm, and fixing the opening direction of the disconnected part of the square ring. The angle range is 45°, the fillet radius of the disconnected part of the square ring is 7 μm, and the disconnected part of the square ring adopts the method of large inside and small outside; set the lithography-related parameters of the lithography marking points of the LED chip after the redesign, uniform The gel soft-baking temperature is 113°C, the exposure dose is 60mJ, the PEB temperature is 106°C, the development time is 100s, and then stand still. According to the parameters, the temperature of the photolithographic marking point of the LED chip is set for vapor deposition, and then the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com