polarizing plate

A polarizing plate and compound technology, applied in polarizing elements, instruments, optical elements, etc., can solve the problems of unsuitable protective film and polarizer bonding, hinder curing, high alkalinity, and achieve excellent curability, improved optical properties, The effect of reducing quality deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

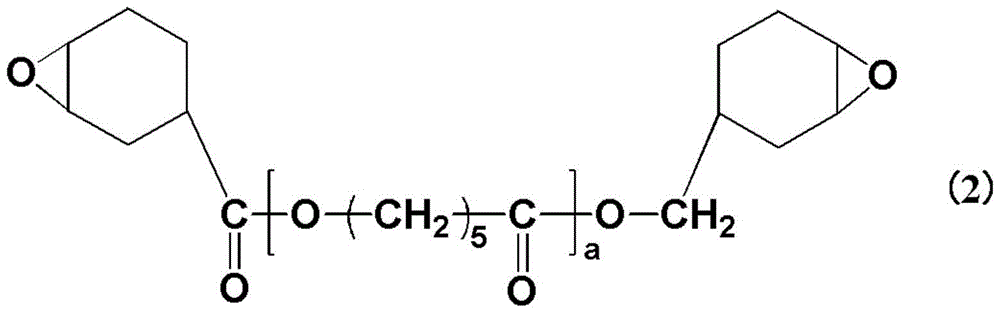

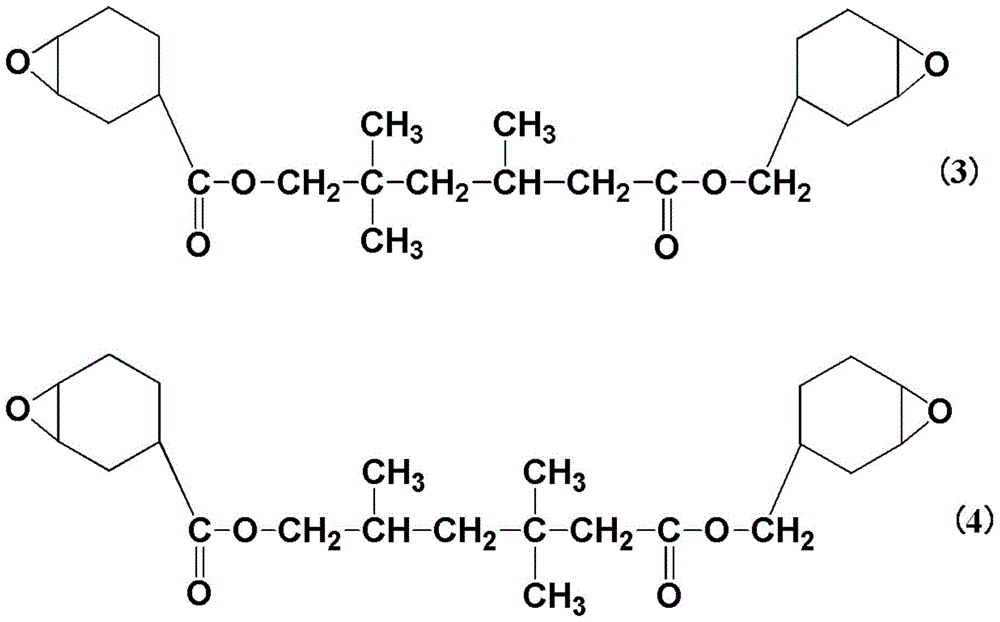

[0128] In a reaction vessel equipped with a stirrer, a reflux condenser, a thermometer, a dropping funnel, and a nitrogen gas inlet, bisphenol F-type glycidyl ether ("EPICLON EXA-830CRP" manufactured by DIC Corporation) as a cationic polymerizable compound was charged. ) 100 parts by mass, two [1-ethyl (3-oxetanyl)] methyl ether 350 parts by mass, 3,4-epoxycyclohexyl carboxylic acid 3,4-epoxycyclohexenyl methyl 250 parts by mass of ester, 300 parts by mass of trimethylolpropane diglycidyl ether, 50 parts by mass of propylene carbonate of diphenyl-4-(phenylthio)phenylsulfonium hexafluorophosphate as a cationic polymerization initiator 80 parts by mass of the solution, 40 parts by mass of 2,4-diethylthioxanthone as a thioxanthone compound, and 10 parts by mass of 1,4-diethoxynaphthalene as a naphthalene compound were mixed and stirred, Thus, a cationically polymerizable adhesive (Y-1) was obtained.

[0129] Prepare 2 sheets of UV-TAC with a urethane primer layer obtained in the...

Embodiment 2~10、 comparative example 1~3

[0131] Except having changed the quantity of the thioxanthone compound and naphthalene compound used, and the kind of protective film as shown in Tables 1-2, it carried out similarly to Example 1, and obtained the polarizing plate.

Embodiment 11

[0133] Change the usage amount of two [1-ethyl (3-oxetanyl)] methyl ether to 300 parts by mass, and 3,4-epoxycyclohexene carboxylic acid 3,4-epoxycyclohexene Except having changed the usage-amount of a methyl ester into 300 mass parts, it carried out similarly to Example 1, and obtained the polarizing plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com