Pulsed power supply for electric precipitation

A pulsed power supply and electrostatic precipitator technology, applied in the field of dust removal systems, can solve the problems that the power frequency power supply of electrostatic precipitators cannot meet environmental protection standards, waste of manpower and material resources, and low dust removal efficiency, so as to solve the problem of anti-corona and increase the dust removal efficiency. , Improve the effect of dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

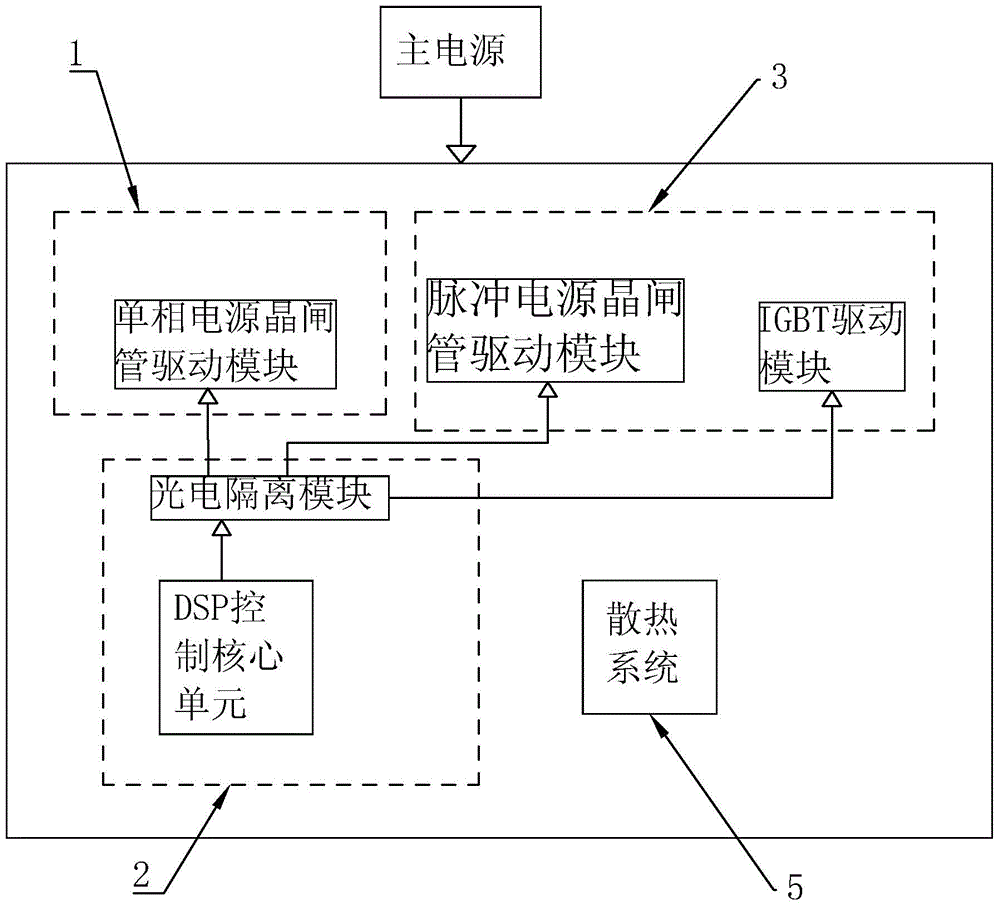

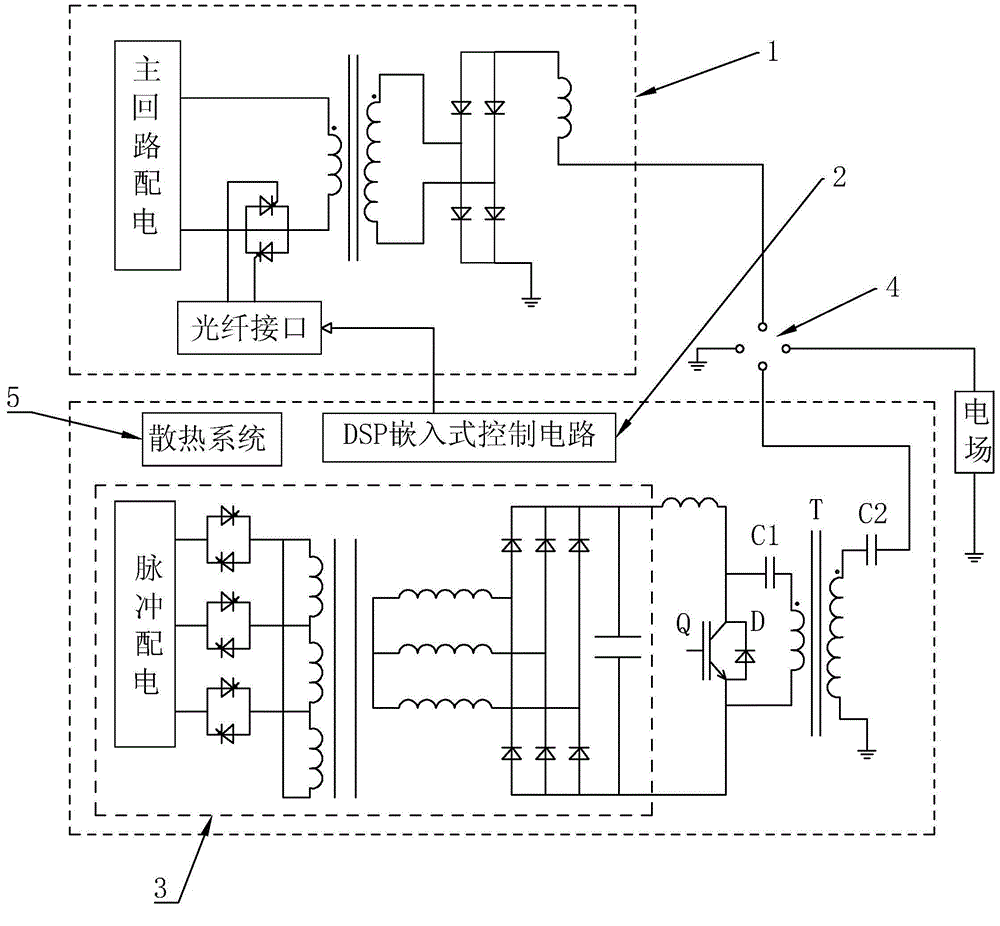

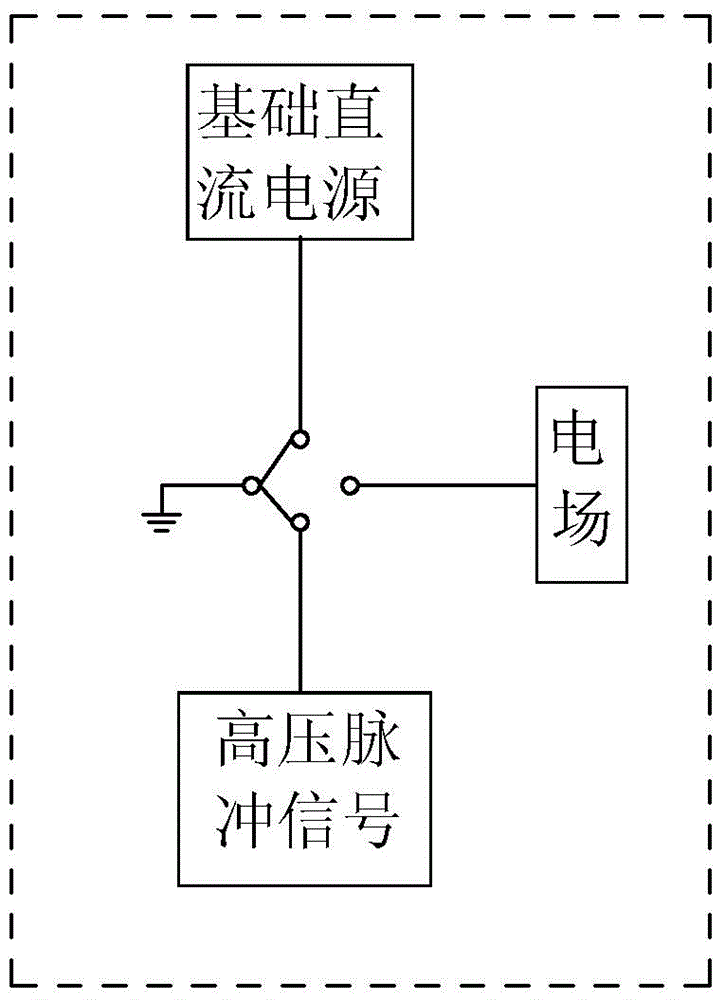

[0027] refer to Figures 1 to 7 As shown, a pulse power supply for electric dust removal in this embodiment includes a main power supply, a DC power supply circuit 1, a DSP embedded control circuit 2, a pulse transformer circuit 3, an isolating switch 4, and a cooling system 5. The main power supply passes through a DC After the power supply circuit 1 outputs a basic DC voltage, the basic DC voltage is used to generate the basic electric field force of the electric dust removal electric field, and the pulse transformer circuit 3 generates a high-voltage pulse signal for the electric dust removal electric field, and the high-voltage pulse signal and the basic electric field The force superposition generates a negative high-voltage voltage signal and acts on the electrostatic precipitator electric field.

[0028] The DSP embedded control circuit 2 outputs control signals for controlling the DC power supply circuit 1 and the pulse transformer circuit 3 respectively, and the isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com