Method of covalent compound modification of potato protein and polysaccharide

A potato protein and composite modification technology, which is applied in plant protein processing and other fields, can solve the problems of unreported potato protein research, achieve the effect of improving stability and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

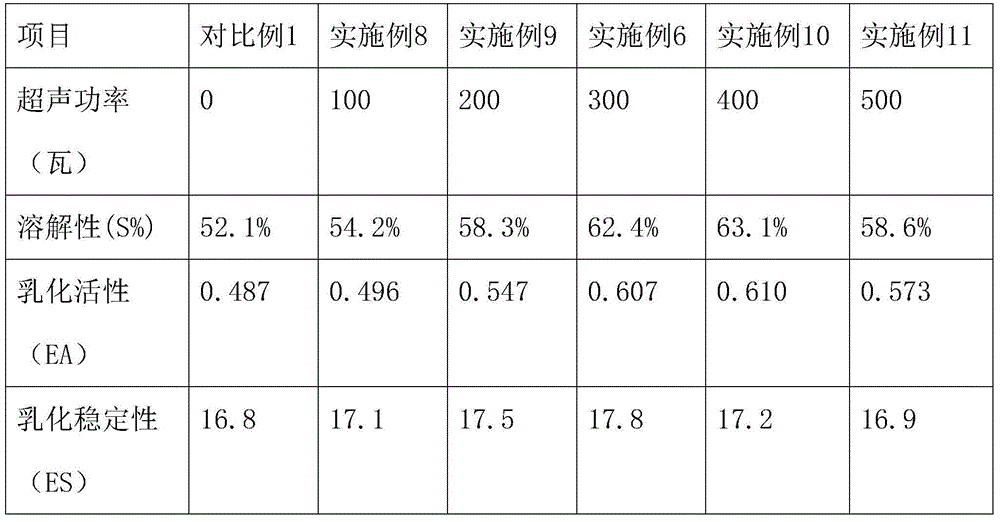

Embodiment 1

[0022] Mix potato protein and distilled water to prepare a potato protein solution with a concentration of 0.03 g / ml, adjust the pH to 8 with NaOH solution, and stir in a water bath at 30°C for 30 minutes to disperse and dissolve. Add xanthan gum to the potato protein solution so that the mass ratio of potato protein to xanthan gum is 2:1, stir in a water bath at 30°C for 20 minutes to disperse evenly, and adjust the pH to 8 with NaOH solution. The obtained mixed solution was ultrasonically treated for 30 minutes at a power of 300 watts, placed at 4° C. for 24 hours, vacuum freeze-dried, pulverized, and transferred to a desiccator. A saturated KBr solution was placed at the bottom of the desiccator to maintain a relative humidity of 70%, and then the desiccator was placed in an incubator at 55° C. to react for 5 days to obtain a covalent complex of potato protein-xanthan gum.

Embodiment 2

[0024] Mix potato protein and distilled water to prepare a potato protein solution with a concentration of 0.02 g / ml, adjust the pH to 8.5 with NaOH solution, and stir in a water bath at 40°C for 20 minutes to disperse and dissolve. Add pectin to the potato protein solution so that the mass ratio of potato protein to pectin is 3:1, stir in a water bath at 40°C for 10 minutes to disperse evenly, and adjust the pH to 8.5 with NaOH solution. The obtained mixed solution was ultrasonically treated for 20 minutes at a power of 400 watts, placed at 2° C. for 20 hours, vacuum freeze-dried, pulverized, and transferred to a desiccator. A saturated KI solution was placed at the bottom of the desiccator to maintain a relative humidity of 65%, and then the desiccator was placed in an incubator at 50° C. for 7 days to obtain a potato protein-pectin covalent complex.

Embodiment 3

[0026] Mix potato protein and distilled water to prepare a potato protein solution with a concentration of 0.06 g / ml, adjust the pH to 7.5 with NaOH solution, stir in a water bath at 30°C for 20 minutes to disperse and dissolve. Add sodium alginate to the potato protein solution so that the mass ratio of potato protein to sodium alginate is 4:1, stir in a water bath at 30°C for 20 minutes to disperse evenly, and adjust the pH to 7.5 with NaOH solution. The obtained mixed solution was ultrasonically treated for 10 minutes at a power of 500 watts, placed at 6° C. for 30 hours, vacuum freeze-dried, pulverized, and transferred to a desiccator. A saturated KI solution was placed at the bottom of the desiccator to maintain a relative humidity of 79%, and then the desiccator was placed in an incubator at 53° C. for 6 days to obtain a covalent complex of potato protein-sodium alginate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com