Cyclodextrin-base comb polypseudorotaxane (CD-PPR) aquagel and preparation method thereof

A technology of polypseudorotaxanes and hydrogels, which is applied in the field of cyclodextrin-based comb polypseudorotaxane hydrogels, and can solve the problems of not using side chain cyclodextrin-based polypseudorotaxanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

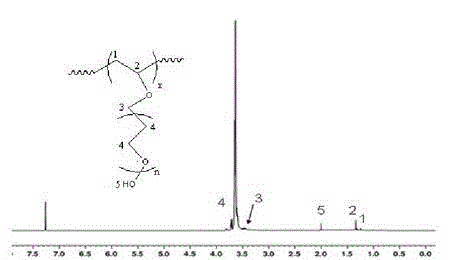

[0021] Step a: Weigh 15 g of APEG-1200 and dissolve it in 20 mL of redistilled DMF solvent, then add 0.3 g of AIBN, react under nitrogen protection at 65°C for 15 h, and distill off the solvent under reduced pressure at 80°C after the reaction , and finally dried under vacuum at 60°C to obtain APEG-1200 polymer. Weigh 5 g of APEG-1200 polymer and dissolve it in 50 mL of water, extract with 150 mL of chloroform, and repeat the operation three times.

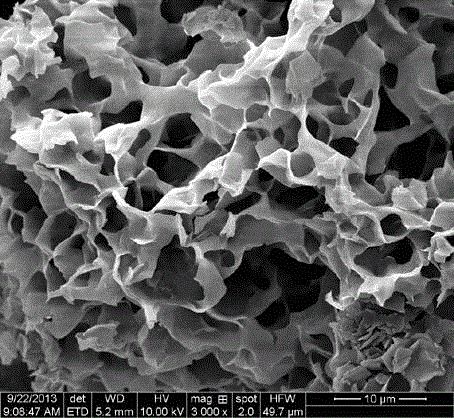

[0022] Step b: Dissolve 0.1 g of the extracted polymer in 1 mL of water, add dropwise to the aqueous solution of 0.03 g / ml α-CD, sonicate for 15 min to make it evenly mixed, and then let the system stand for 12 h, A hydrogel is formed. At this time, the polyoxyethylene segment (CH 2 CH 2 O) to the molar ratio of α-CD (n(CH 2 CH 2 O) / n(α-CD)) is 6.

Embodiment 2

[0024] Step a: Weigh 15 g of APEG-1200 and dissolve it in 20 mL of redistilled DMF solvent, then add 0.6 g of AIBN, react under nitrogen protection at 70°C for 15 h, and distill off the solvent under reduced pressure at 80°C after the reaction , and finally dried under vacuum at 60°C to obtain APEG-1200 polymer. Weigh 5 g of APEG-1200 polymer and dissolve it in 50 mL of water, extract with 150 mL of chloroform, and repeat the operation three times.

[0025] Step b: Dissolve 0.1 g of the extracted polymer in 1 mL of water, add dropwise to the α-CD aqueous solution with a concentration of 0.05 g / ml, sonicate for 15 min to make it evenly mixed, and then let the system stand for 12 h. A hydrogel is formed. At this time, the polyoxyethylene segment (CH 2 CH 2 O) to the molar ratio of α-CD (n(CH 2 CH 2 O) / n(α-CD)) is 4.

Embodiment 3

[0027] Step a: Weigh 15 g APEG-1200 and dissolve it in 20 mL redistilled DMF solvent, then add 0.9 g AIBN, react under nitrogen protection at 75 °C for 15 h, and distill off the solvent under reduced pressure at 80 °C after the reaction , and finally dried under vacuum at 60°C to obtain APEG-1200 polymer. Weigh 5 g of APEG-1200 polymer and dissolve it in 50 mL of water, extract with 150 mL of chloroform, and repeat the operation three times.

[0028] Step b: Dissolve 0.1 g of the extracted polymer in 1 mL of water, add dropwise to the α-CD aqueous solution with a concentration of 0.09 g / ml, sonicate for 15 min to make it evenly mixed, and then let the system stand for 12 h. A hydrogel is formed. At this time, the polyoxyethylene segment (CH 2 CH 2 O) to the molar ratio of α-CD (n(CH 2 CH 2 O) / n(α-CD)) is 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com