Method for harmlessly treating arsenic-containing waste slag and comprehensively recycling valuable metals in arsenic-containing waste slag

A valuable metal and waste slag technology, applied in chemical instruments and methods, arsenic compounds, inorganic chemistry, etc., can solve the problems of low direct recovery rate of valuable metals, arsenic pollution, low comprehensive recycling rate, etc., to solve arsenic pollution Problems, adaptation to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

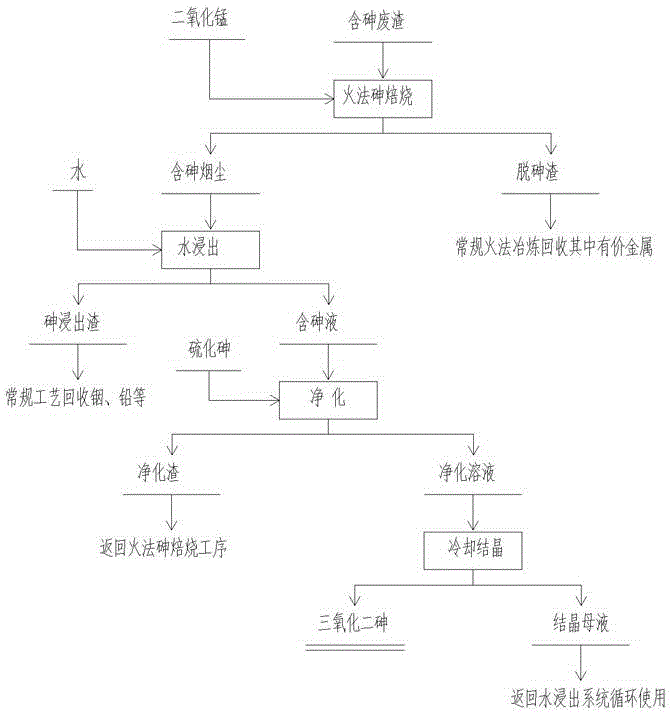

Image

Examples

Embodiment approach 1

[0014] Take 5 tons of raw material and grind it finely, which contains 6.89% arsenic, 7.68% bismuth and 35.32% lead;

[0015] (1) Roasting for arsenic removal: at a temperature of 600-650°C, add 200kg of oxidant manganese dioxide, and roast in a rotary kiln for 6 hours. 1132kg of arsenic-containing dust and 4035.8kg of arsenic-removed slag were obtained. Among them, the arsenic-containing dust contains 28.58% arsenic, 7.28% bismuth, and 33.67% lead; the arsenic-removed slag contains 0.52% arsenic, 7.47% bismuth, and 34.32% lead. The removal rate of arsenic is 93.91%;

[0016] (2) Water leaching of arsenic-containing soot: put the arsenic-containing soot obtained in the previous step at a temperature of 85-95°C for 3-4 hours, add 25t of water, leaching and filtering to obtain an arsenic-containing solution of 21.18m 3 It contains 15.07g / L of arsenic and 700.5kg of arsenic leaching slag, which contains 0.61% of arsenic, 53.86% of lead and 11.64% of bismuth;

[0017] (3) Purif...

Embodiment approach 2

[0020] Take 1 ton of raw material and grind it finely, which contains 19.8% arsenic, 15.2% bismuth, 16.3% copper, and 15.8% lead;

[0021] (1) Roasting for arsenic removal: at a temperature of 600-650°C, add 4kg of oxidant manganese dioxide, and roast in a reverberatory furnace for 6 hours. 352.12kg of arsenic-containing dust and 685.38kg of arsenic-removed slag were obtained. Among them, the arsenic-containing dust contains 54.94% arsenic, 7.91% bismuth, 9.56% lead, and 4.22% copper; the arsenic removal slag contains 0.66% arsenic, 18.11% bismuth, 18.14% lead, and 21.61% copper. The removal rate of arsenic is 97.72%;

[0022] (2) Water leaching of arsenic-containing soot: put the arsenic-containing soot obtained in the previous step at a temperature of 85-95°C for 3-4 hours, add 7t of water, leaching and filtering to obtain 6830L of arsenic-containing solution, which contains 28.19g / L of arsenic and 112.53kg of arsenic leaching residue, containing 0.81% arsenic, 29.61% lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com