Double flow circulating fluidized bed steam injection boiler with buried pipe and evaporation coil

A circulating fluidized bed and evaporating coil technology, which is applied in steam boilers, boiler water pipes, steam generation, etc., can solve the problems of heat transfer deterioration, water-cooled wall tubes are prone to salt scale formation, and pipe bursts, etc., to eliminate the disadvantages of pipe bursts , to ensure safe and stable operation, and to solve the effect of pipe burst problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

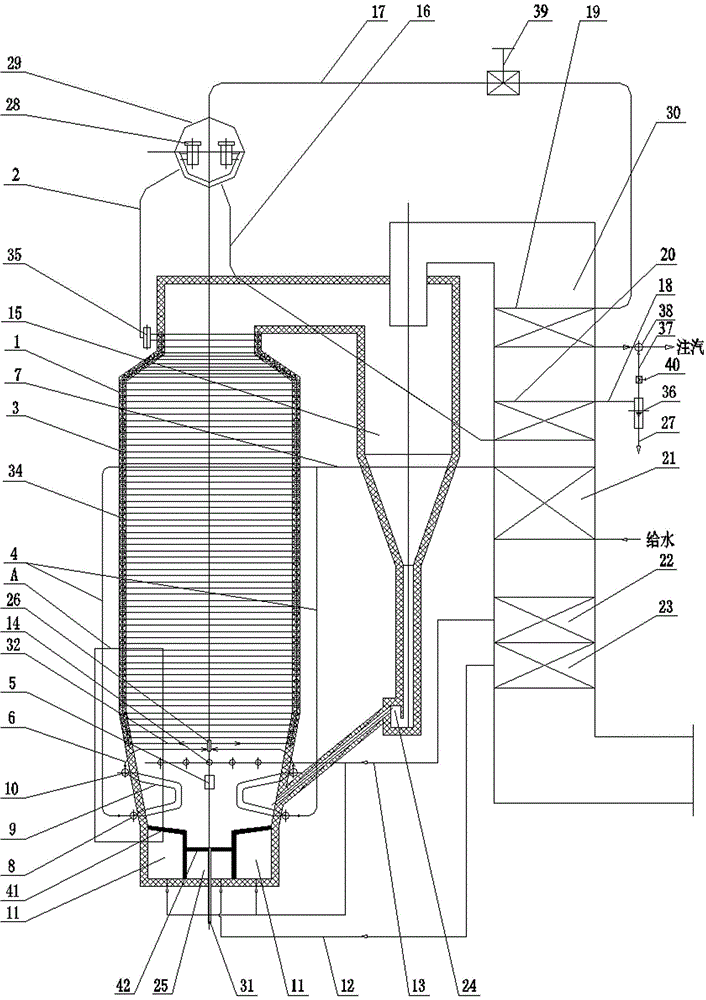

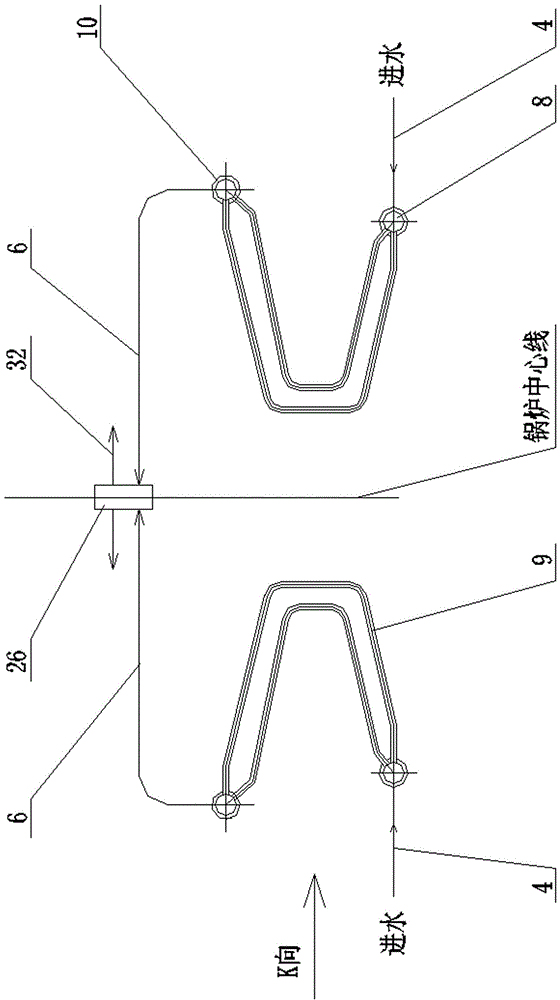

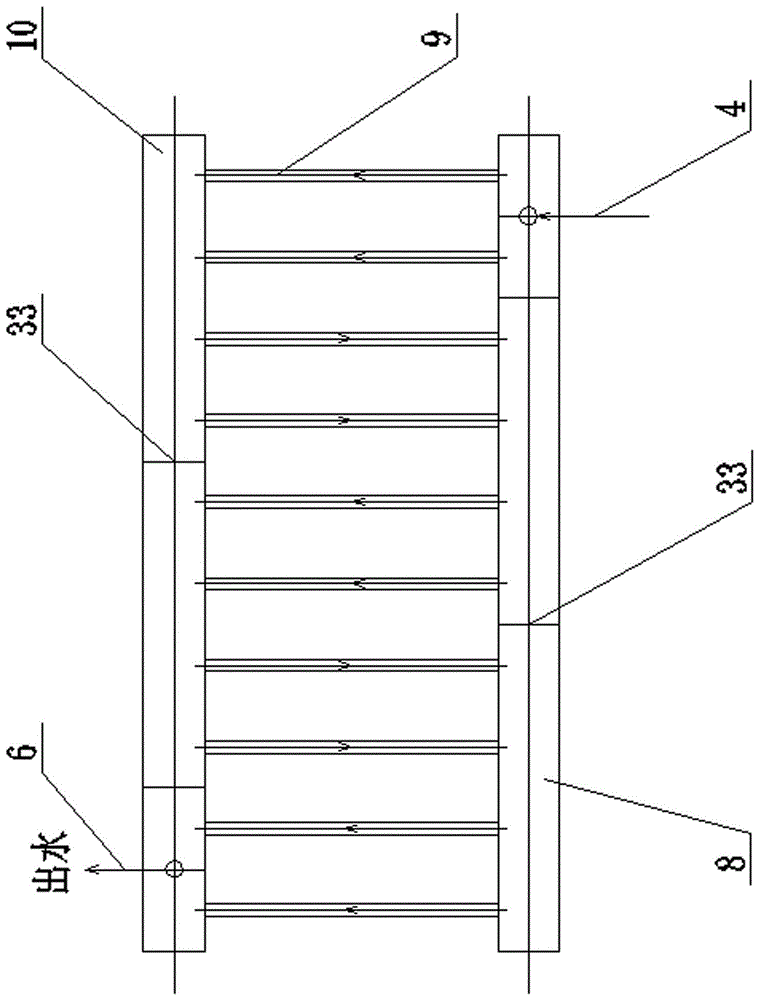

[0018] Specific implementation mode one: as Figure 1~Figure 4As shown, the double-flow circulating fluidized bed steam injection boiler with buried pipe and evaporation coil includes furnace body 1, connecting pipe 1, coal inlet 5, economizer water outlet main pipe 7, low-velocity bed air chamber 11, primary Air duct 12, secondary air duct 13, secondary air pipe 14, cyclone separator 15, connecting pipe six 16, steam connecting pipe 17, superheater 19, DC evaporator 20, economizer 21, secondary air air preheater Heater 22, primary air preheater 23, return valve 24, high-speed bed air chamber 25, sewage pipe 27, steam drum 29, tail flue 30, slag discharge pipe 31, low-speed bed air distribution plate 41, high-speed bed Air distribution plate 42, two connecting pipes two 4 and two connecting pipes three 6; the furnace body 1 is a circulating fluidized bed; the steam drum 29 is provided with a steam-water separator 28, and the furnace body A high-speed bed air chamber 25 is pro...

specific Embodiment approach 2

[0020] Specific implementation mode two: as figure 1 As shown, the double-flow circulating fluidized bed steam injection boiler with buried pipes and evaporation coils described in the first embodiment, the steam connecting pipe 17 is equipped with an electric valve one 39, and the connecting pipe seven 37 An electric valve 2 40 is installed on it to ensure the resistance balance of the superheater 19 and the evaporator 20, thereby realizing system pressure balance.

specific Embodiment approach 3

[0021] Specific implementation mode three: as figure 1 As shown, in the double-flow circulating fluidized bed steam injection boiler with buried pipes and evaporation coils described in Embodiment 1, the number of the evaporation coils 3 is 1 to 6, and the outer diameter of the evaporation coils 3 is (diameter) is Φ51mm~Φ108mm to meet the needs of steam injection boilers with a capacity of 7~130t / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com