A Finned Tube Fluidized Bed Heater

A heat extractor and finned tube technology, which is applied in the field of finned tube fluidized bed heat extractors, can solve the problems of unresolved thermal stress and unresolved finned tubes, etc., so as to reduce the occurrence of local dead zones The probability of the increase in the degree of turbulence, the effect of heat transfer process intensification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

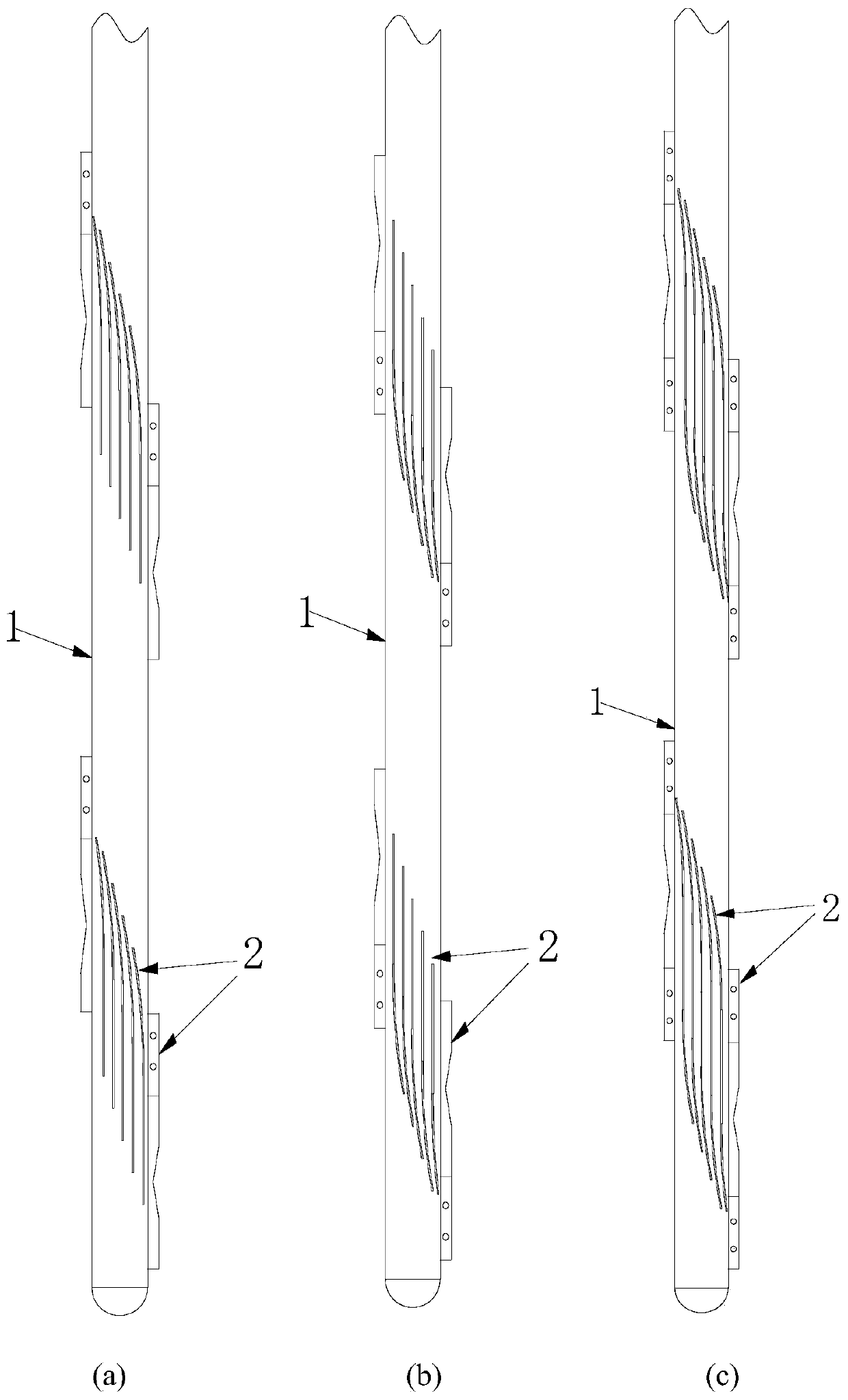

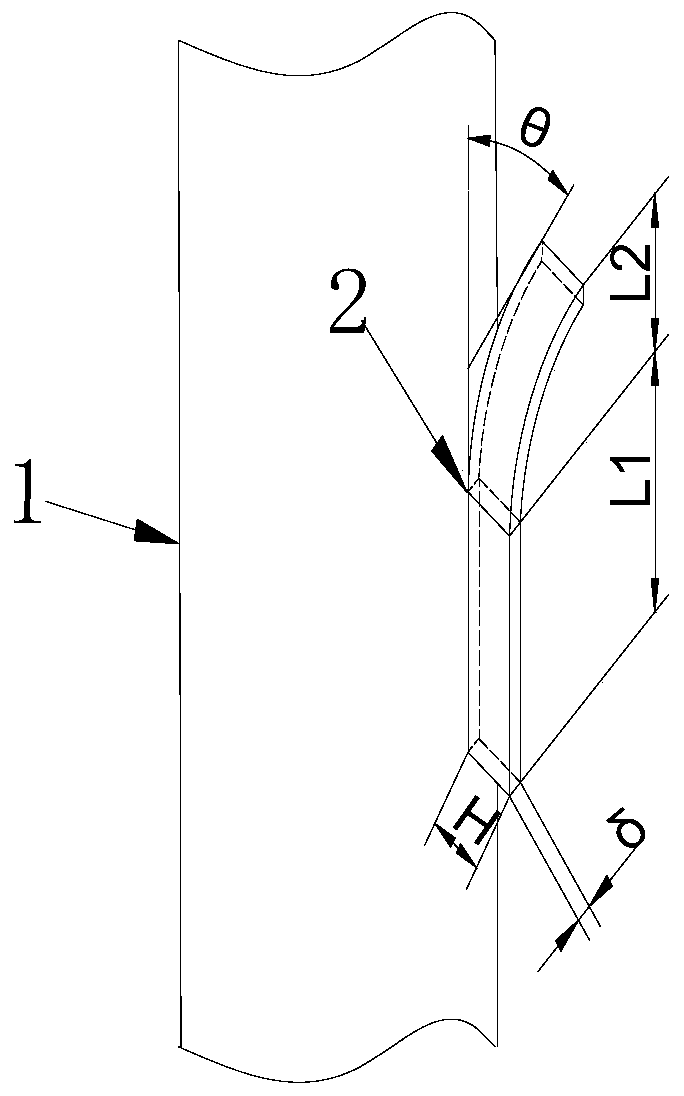

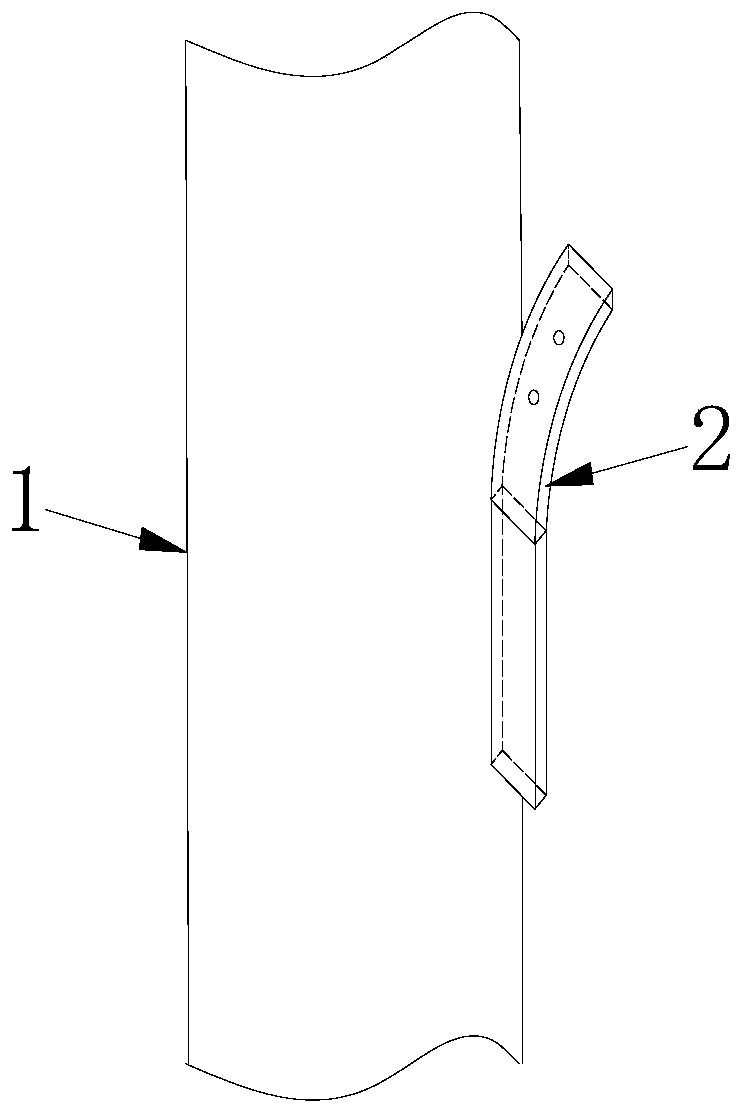

[0050] figure 1 As an example of combined finned tube implementation, the three types of fins 2 are reasonably combined to obtain combined finned tubes, so that the secondary flow caused by the three types of fins 2 near the surface of the finned tube is common When the effect occurs, the fluid disturbance intensity is significantly increased, and the heat transfer coefficient can be increased by 20-40%; the boundary layer on the surface of the finned tube is destroyed, and the heat transfer resistance is reduced; The contact between B and the finned tube is more sufficient; the existence of the fin 2 increases the heat transfer area; the fin 2 is installed in a spiral form, which disperses the thermal stress and solves the problem of tube explosion caused by the stress concentration of the finned tube.

Embodiment 2

[0052] Image 6 For the combined finned tube heat extractor of the present invention, in the shell side, the catalyst B to be cooled enters the heat extractor from the catalyst inlet pipeline, and under the action of fluidizing wind A, the catalyst B to be cooled flows convectively with the finned tube After the heat exchange, the cooling catalyst C flows out from the catalyst outlet at the bottom of the heat collector; in the tube side, water D flows in from the upper casing of the finned tube, and after heat exchange with the catalyst, it becomes water vapor E from the upper steam outlet of the finned tube discharge. Figure 7 For the tube bundle layout diagram of the external heat extractor of the present invention, the novel finned tubes are arranged according to Figure 7 Installed in the arrangement shown, the secondary flow on the surface of each finned tube will disrupt the entire flow field of the heat collector, thereby increasing the turbulence of the entire shell-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com