Ultrasonic wave opposite irradiation type water meter

An ultrasonic, through-beam technology, applied in the mechanical field, can solve the problem of large measurement error, and achieve the effect of small measurement error, accurate measurement, and reduction of distance and loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

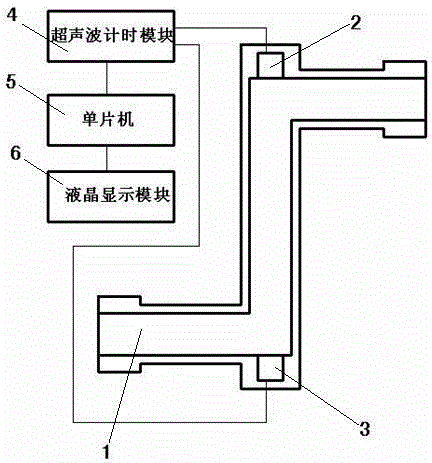

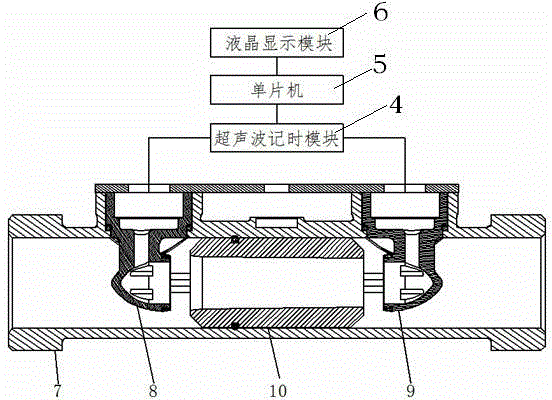

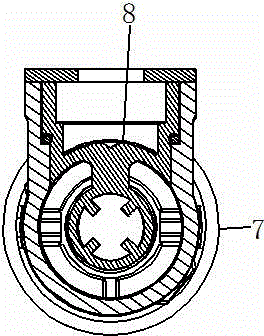

[0010] Such as figure 2 and image 3 As shown, an ultrasonic through-beam water meter is mainly composed of a water meter main body 7, a front ultrasonic transducer 8, a rear ultrasonic transducer 9, a measuring tube 10, an ultrasonic timing module 4, a single-chip microcomputer 5 and a liquid crystal display module 6. The feature is that: the main body of the water meter 7 is equipped with two opposite-beam transducers, respectively, the front ultrasonic transducer 8 and the rear ultrasonic transducer 9, the two opposite-beam transducers are connected to the measuring tube 10 in the middle, and the two opposite-beam transducers are connected to each other. The radial transducer is completely attached to the wall of the measuring tube 10. The front ultrasonic transducer 8 and the rear ultrasonic transducer 9 are connected to the ultrasonic timing module 4 through signal lines, and the connection length is the same. The ultrasonic timing module 4 and the single-chip microcompu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com