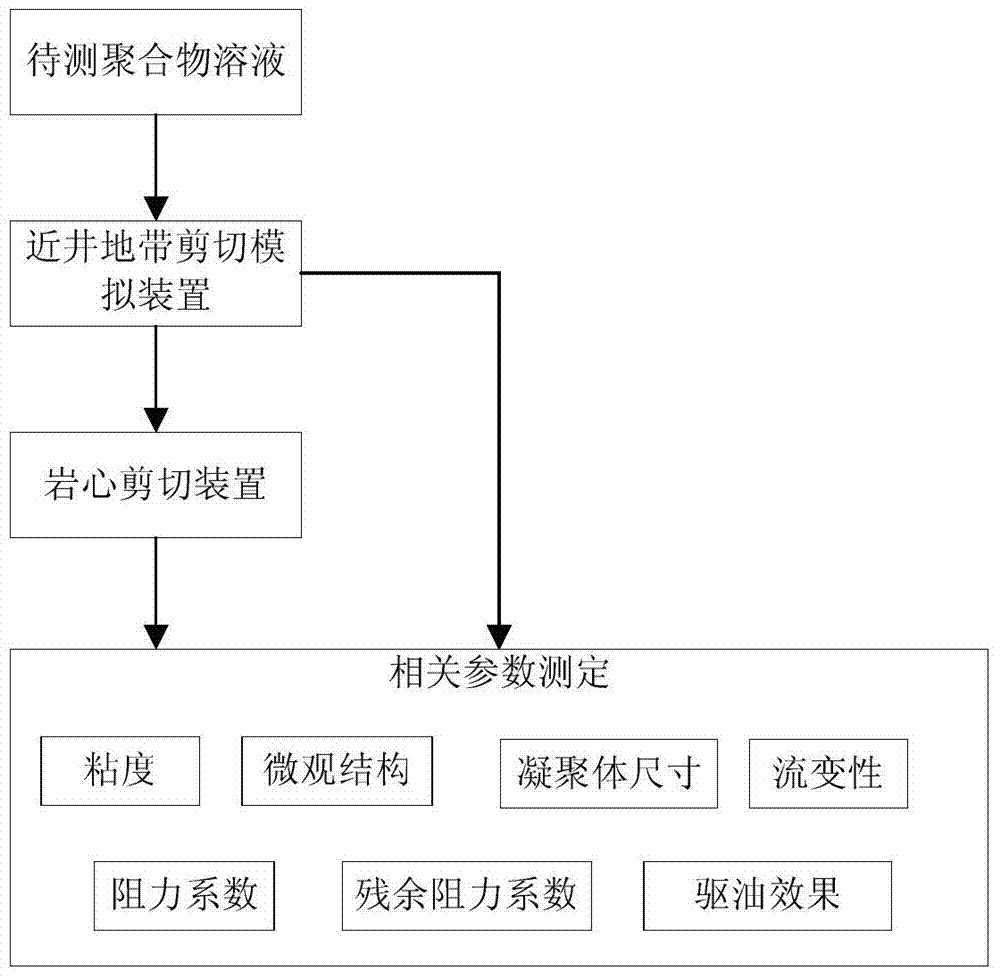

Secondary Shear Method for Determination of Performance Parameters of Polymer Solutions for Oil Displacement

A polymer solution and polymer technology, applied in the direction of DC flow characteristics measurement, etc., can solve the problems of actual value gap, only suitable for simulating the shear at a certain point in the formation, and cannot fully reflect all shear, etc., to achieve performance Accurate parameters, solving time-consuming and laborious on-site measurement, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

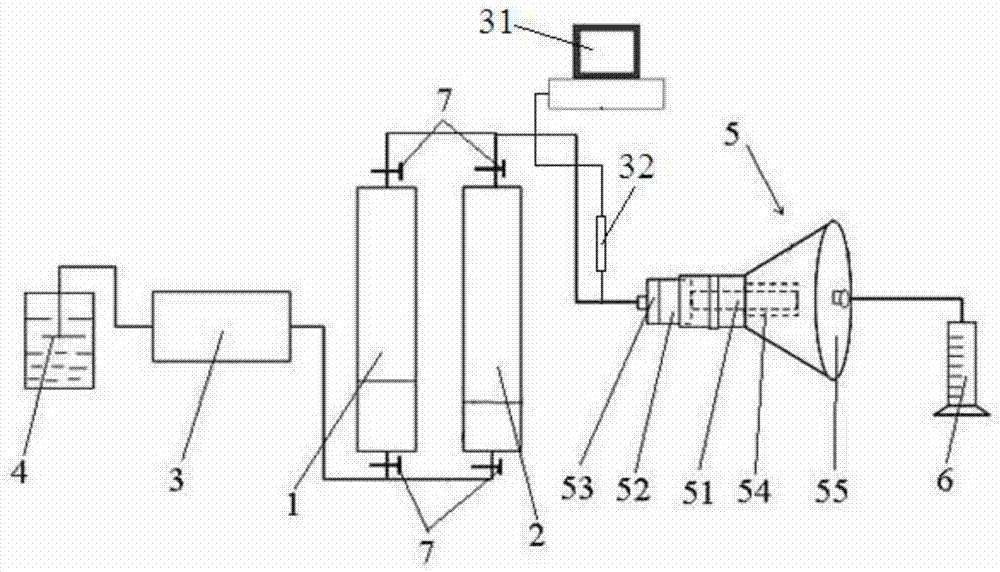

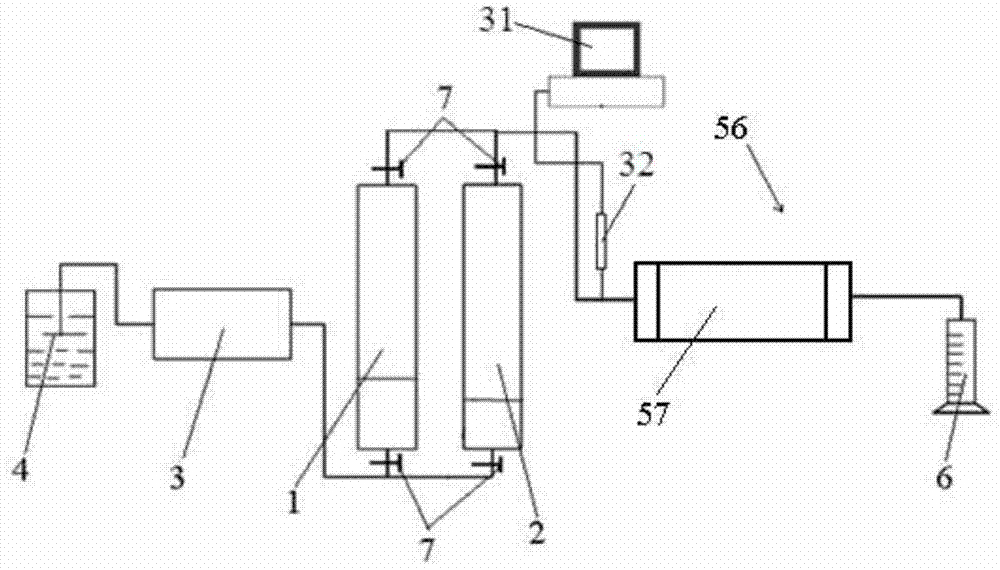

Method used

Image

Examples

Embodiment

[0060] Taking a certain oil field as an example below, the two-stage shearing experimental method for measuring the performance parameters of the polymer solution for oil displacement provided by the present invention is specifically introduced:

[0061] In this embodiment, the experimental apparatus and materials are as follows:

[0062] (1) Viscometer: Brookfield DV-Ⅲ viscometer, produced by American Brookfield Company. Test conditions: the shear rate is 7.34s -1 ; The test range of different types of rotors is shown in Table 3.

[0063] Table 3 Viscosity measurement range of different spindles

[0064] rotor

00#

61#

62#

63#

31#

Speed(r / min)

6

18.5

18.8

27.3

21.6

[0065] Shear rate (s -1 )

7.34

7.37

7.4

7.35

7.34

Viscosity Range (mPa·s)

0~100

100~320

100~1500

>1500

100~1389

[0066] (2) Electronic balance: range 20g ~ 3000g, precision 0.01g;

[0067] (3) Constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com