Secondary shear test method for determining performance parameters of polymer solutions for oil displacement

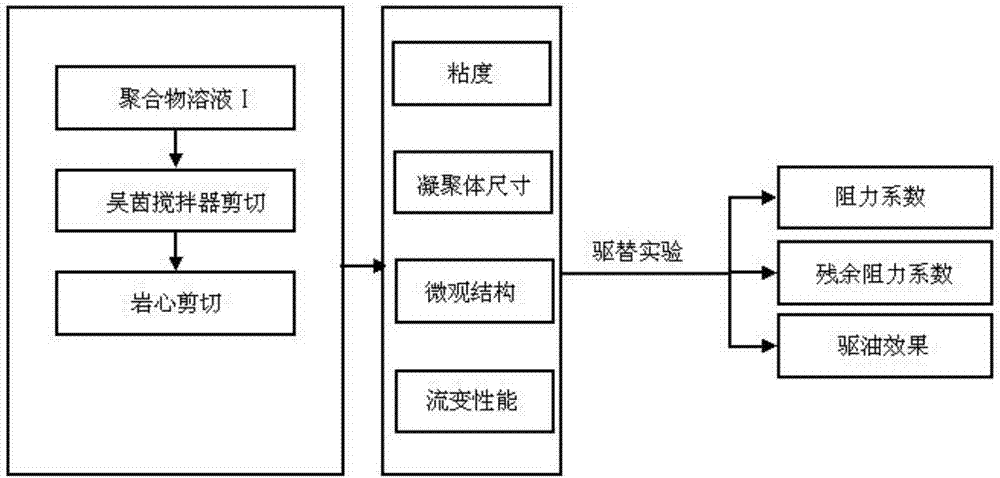

A technology of polymer solution and experimental method, which is applied in the field of secondary shear experiment for determining the performance parameters of polymer solution for oil displacement, can solve the gap, cannot fully reflect the full shear of polymer solution, and cannot accurately and completely Reflect problems such as polymer solution shearing to achieve accurate performance parameters and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

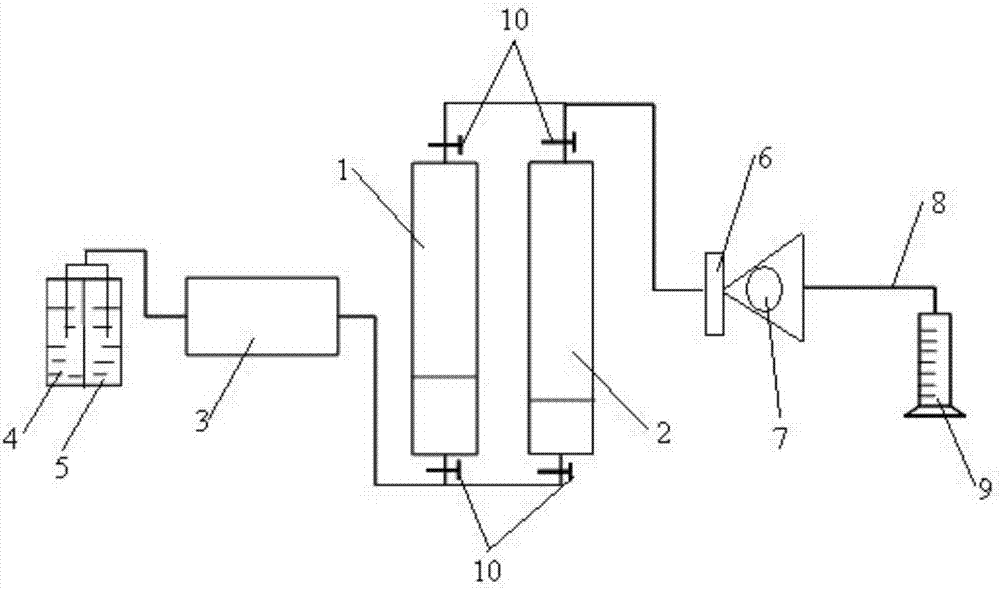

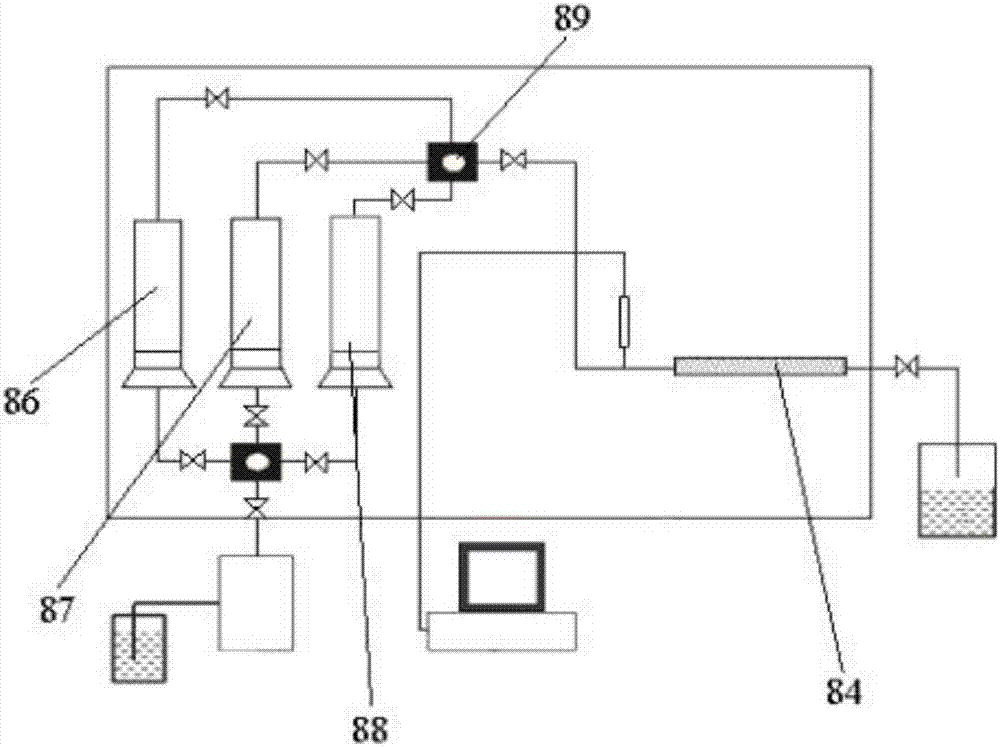

Method used

Image

Examples

Embodiment

[0029] Embodiment: Taking a certain oil field as an example, describe in detail the secondary shear test method for measuring the performance parameters of the polymer solution for oil displacement, which includes the following steps:

[0030]1) Preparation of polymer solution for experiment Ⅰ: Measure the oilfield water, weigh the dry polymer powder, stir the oilfield water with a mixer to form a vortex, and place the weighed polymer within 30 seconds at a distance of 2 / 3 to 3 / 4 from the center of the vortex. Throw all the dry polymer powder into the oilfield water, keep stirring, stop stirring after the dry polymer powder is completely dissolved, and obtain the mother liquor of polymer solution I, dilute the mother liquor of polymer solution I with oilfield water to obtain a polymer with a concentration of no more than 5000mg / L Solution I.

[0031] Wherein, the oilfield water is prepared according to the formation water of a certain oilfield, and its preparation method inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com