Gas permeation test device and method for fractured coal rock

A technology for gas permeation testing and crushing coal and rock mass, which is applied in the field of seepage of coal and rock mass, and can solve the problems of restricting the measurement accuracy of axial displacement, affecting the accuracy of gas permeation parameters, and the transmission is not tight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

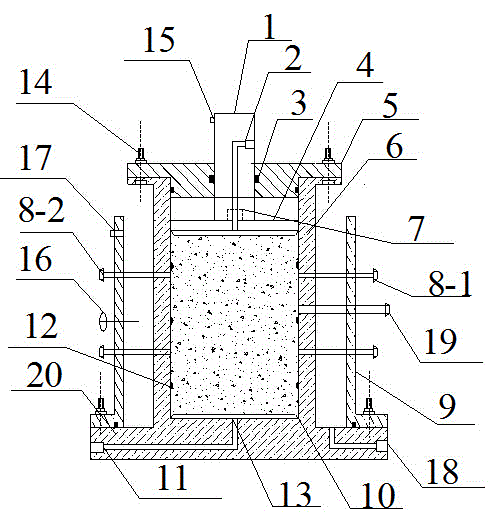

[0032] This embodiment provides a gas permeation test device for broken coal and rock mass.

[0033] Such as figure 1 As shown, the device includes a cylinder 6, the top of the cylinder 6 is provided with a gland 5, and the bottom of the cylinder 6 is a base 20;

[0034] The outside of the cylinder 6 is provided with a temperature control chamber 9, the temperature control chamber 9 is composed of a cylinder, and the lower part of the cylinder is connected to the base 20 by bolts,

[0035] The gland 5 is a stepped structure, the center of the gland 5 is provided with a through hole, the push head 1 passes through the through hole, the lower part of the push head 1 is connected with the push plate 4 through the thread 7, the push head 1 and the push plate 4 There is an air outlet 2 connected to the inside of the cylinder, and a displacement sensor 15 is arranged above the push head 1; a pressure sensor 12 is evenly arranged on the inner wall of the cylinder 6, and air holes ar...

Embodiment 2

[0043] To study seepage properties of broken coal and rock mass at different temperatures.

[0044] This embodiment is realized through the following steps:

[0045] 1) Sieve the broken coal body with sand and stones of different particle sizes into broken coal bodies with a particle size of 2.5~5mm;

[0046] 2) Continuously circulate water at 40°C from the water inlet (17) and water outlet (18);

[0047] 3) Open the gland (5), pour the crushed coal with a particle size of 2.5~5mm into the cylinder (6) to make it evenly and naturally accumulate, then close the gland (5), and tighten the screw (14) to realize the cylinder body (6) seal;

[0048] 4) Vacuumize the crushed coal in the cylinder (6) through the vacuum hole (19);

[0049] 5) Continuously inject methane at a pressure of 0.2MPa into the cylinder (6) to saturate the sample;

[0050] 6) Inject 0.2MPa methane gas from the air inlet (11), record the initial flow and pressure of the gas inlet and outlet (2), and control...

Embodiment 3

[0057] The seepage characteristics of broken coal and rock mass under different pressure difference conditions are studied.

[0058] 1) Sieve the broken coal body with sand and gravel sieves of different particle sizes into broken coal bodies with a particle size of 10-12.5mm;

[0059] 2) Open the gland (5), pour the crushed coal with a particle size of 10~12.5mm into the cylinder (6) to make it evenly and naturally accumulate, then close the gland (5), and tighten the screw (14) to realize Cylinder body (6) seal;

[0060] 3) Vacuumize the crushed coal in the cylinder (6) through the vacuum hole (19);

[0061] 4) Continuously inject methane with a pressure of 60kPa into the cylinder (6) to saturate the sample;

[0062] 5) Inject 60kPa methane gas from the air inlet (11), and inject 10kpa methane from the side wall air inlet (8-1) at the same time, and record the initial air inlet and outlet (2), side wall air outlet (8-1) 2) Flow rate and pressure; keep injecting 60kPa meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com