A method for rapid preparation of rebco superconducting film by extremely low fluorine mod method

A superconducting film, extremely low technology, applied in the field of preparation of the second-generation high-temperature superconducting coated conductor REBCO, can solve the problems of superconducting layer void composition, poor performance superconducting film, film surface deterioration, etc. Solution rate, time shortening, effect of shortening heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention are described in detail as follows:

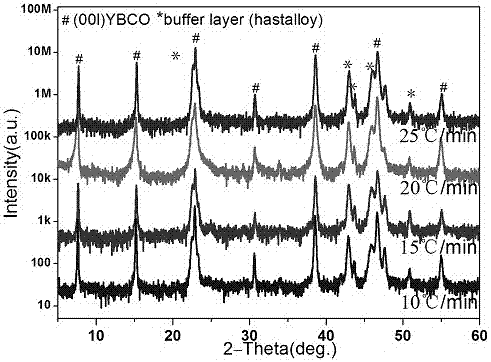

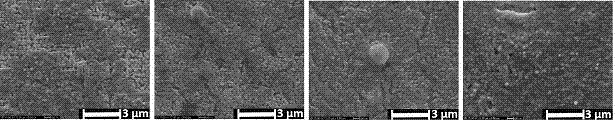

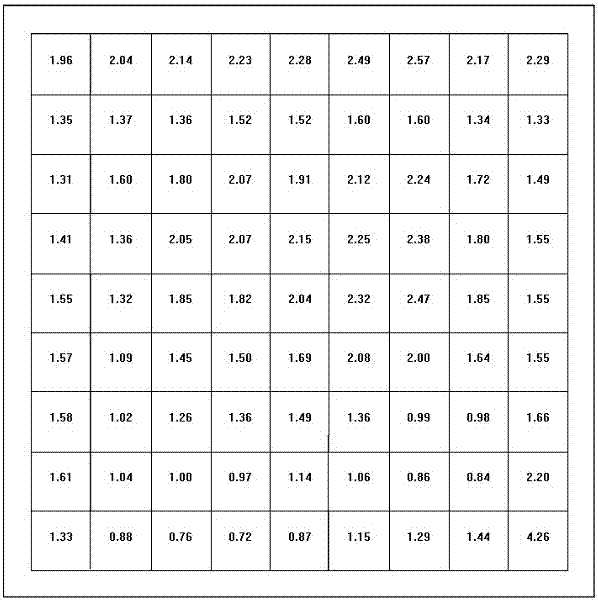

[0026] In this example, see Figure 1 ~ Figure 4 , a method for rapidly preparing a REBCO superconducting film by an extremely low-fluorine MOD method, comprising the steps of:

[0027] a. by the mol ratio of RE:Ba:Cu=1:1.5:3, take respectively yttrium acetate tetrahydrate, barium acetate and copper acetate monohydrate of 0.005mol, 0.0075mol and 0.015mol;

[0028] b. Mix and dissolve all the rare earth acetates, all copper acetate and 2 / 3 barium acetate weighed in step a in deionized water, stir well and then add an excess of 1 times propionic acid, and then stir for 2 The mixed solution was fully reacted in 1 hour, and then the solvent was distilled off with a rotary evaporator to obtain a gel under reduced pressure;

[0029] c. Dissolve the other 1 / 3 of the barium acetate weighed in step a in deionized water, stir well and then add an excess of 30% trifluoroacetic acid, stir to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com