Mode-controlled laser pen for controlling fine particles

A technology of laser pointers and microparticles, applied in the field of lasers, can solve the problems of low resolution of spatial light modulators, low damage threshold of spatial light modulators, and optical conversion efficiency of less than 1,000 percent, achieving exquisite appearance and low production costs. Low, high peak power effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

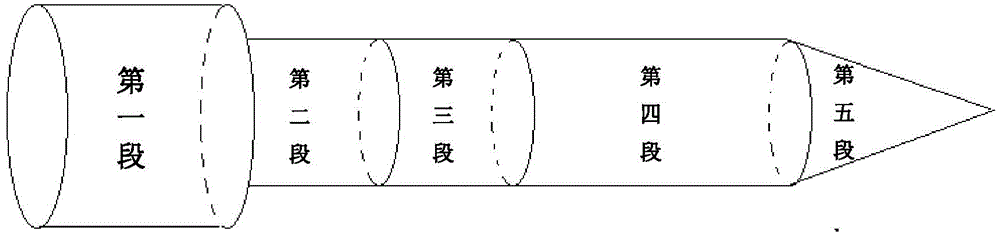

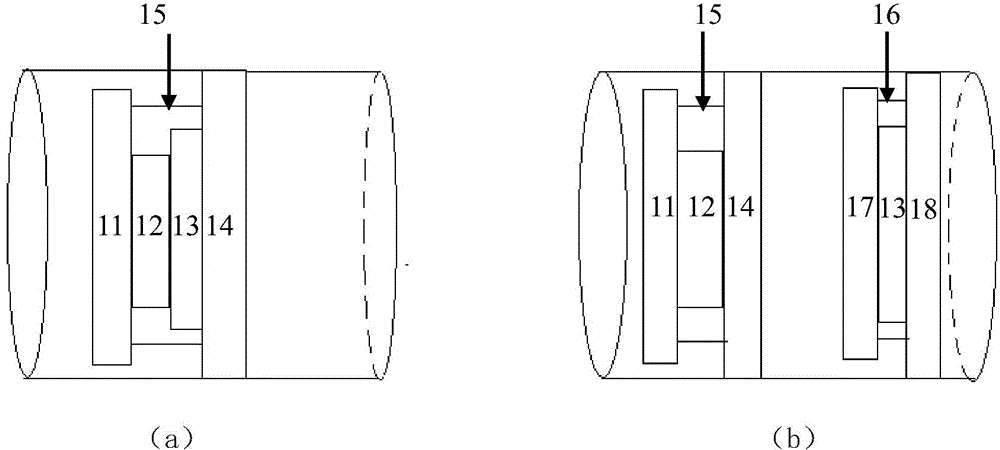

[0029] The present invention uses the structure of generating multiple laser modes by breaking the symmetry of the resonator in the miniaturized all-solid-state laser, and can realize the scheme of controllable laser modes. The high-brightness 808nm semiconductor laser diode is end-pumped with Cr and Nd coated at both ends. :YAG double-doped crystal generates IG mode as an example.

[0030] The high-brightness single-tube diode pump source can be a high-brightness 808nm semiconductor laser diode; the laser working material layer can be selected from Cr, Nd: YAG double-doped crystal, and the back surface of this crystal is coated with a 1064nm high-reflection film and an 808nm Antireflection coating, the front surface is coated with 1064nm antireflection coating and 808nm high reflection coating.

[0031] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

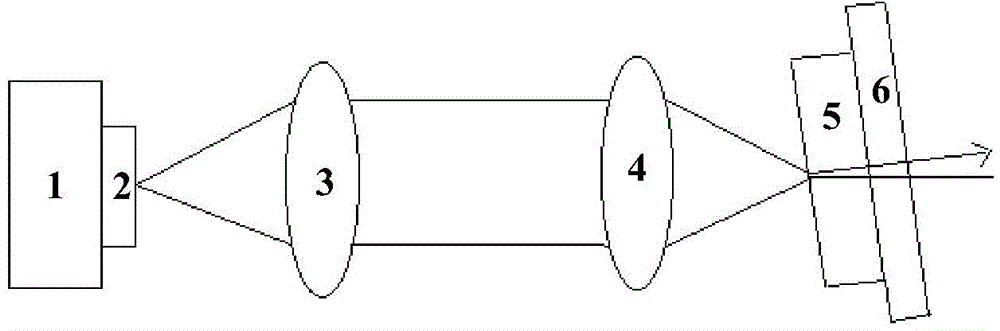

[0032] see figure 1 , the embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com