Hollow fiber membrane filter element potting mold and using method thereof

A technology for potting molds and fiber membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficulty in demoulding, improve potting efficiency, reduce adhesion, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

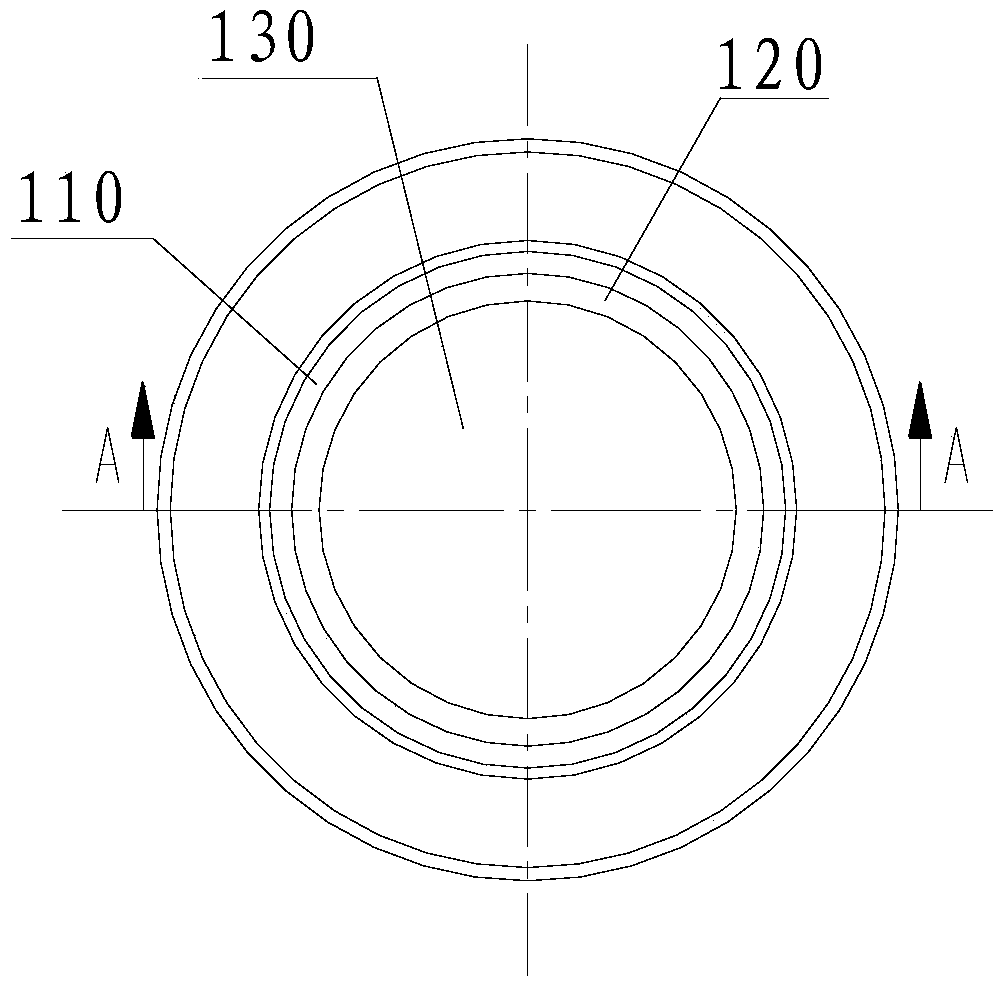

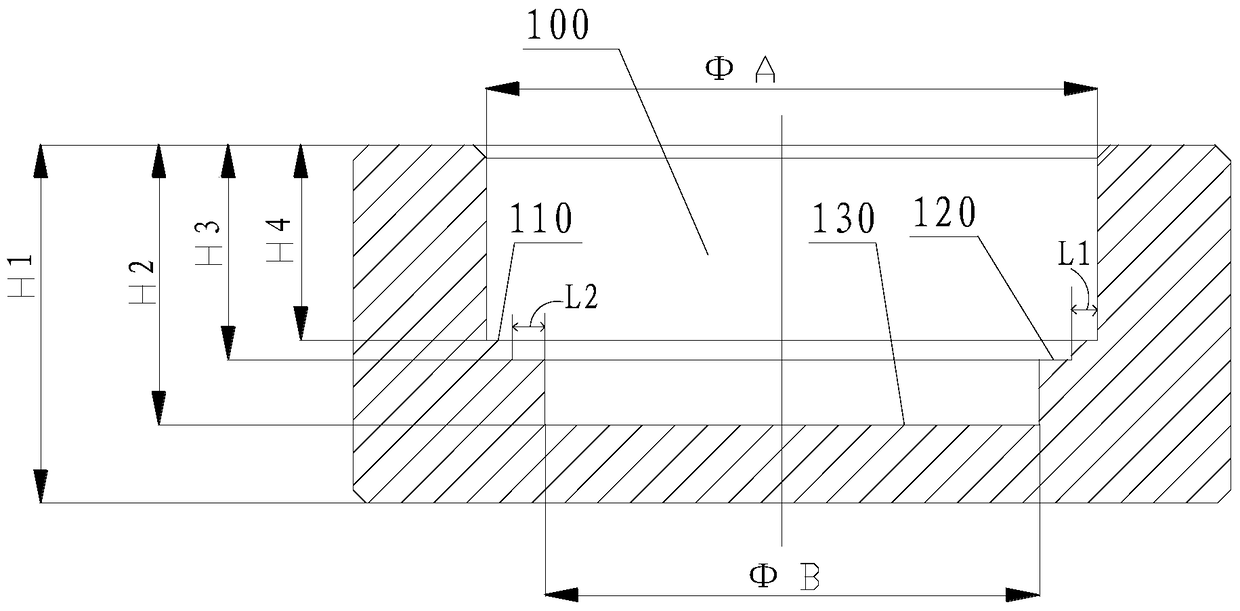

[0038] see figure 1 with figure 2 , is an embodiment of the hollow fiber membrane potting mold of the present invention, in this embodiment, the potting mold is composed of a concentric cylinder with a closed bottom, and the inner cavity thereof forms a holding tank 100 . The storage tank 100 has the following characteristics: the inner wall of the storage tank 100 is provided with a first step 110 and a second step 120, and the second step 120 is close to the bottom 130 of the storage tank 100; the bottom 130 of the storage tank 100 is a plane ; The storage tank 100 is made of silicon rubber with a hardness of 90 degrees.

[0039]Specifically, in this embodiment, the outer diameter ΦA of the first step 110 is 94 mm, and the width L1 (half of the difference between the outer diameter ΦA of the first step 110 and its inner diameter) is 4 mm; the width L2 of the second step 120 ( Half of the difference between the outer diameter of the second step 120 and its inner diameter) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com