Hole machining device

A hole processing and tapered hole technology is applied in the field of electric heating plate production and processing equipment, which can solve the problems affecting the performance of mica materials, the bulge of the material in and out, and the wire drawing, so as to facilitate the drilling quality, improve the drilling performance, The effect of increasing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

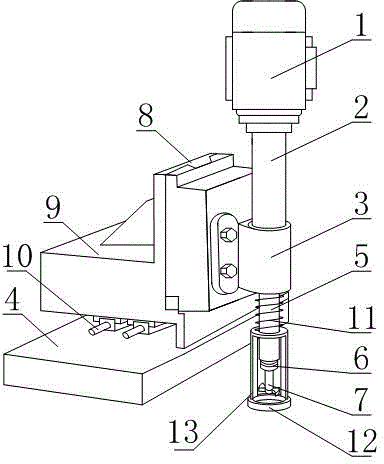

[0022] Such as figure 1 , a hole processing device, comprising a motor 1, a rotating shaft 5, a drill clamp 6 and a drill bit 7, the drill clamp 6 is fixedly connected to the rotating shaft 5 of the motor 1, the drill clamp 6 is held on the drill clamp 6, and also includes The mica board compacting part, the vertical lifting system and the horizontal knife system, the mica board compacting part includes a compacting spring 11 and a compacting plate 12, and the compacting spring 11 is sleeved on the rotating shaft 5 , and one end of the compression spring 11 is fixed on the housing of the motor 1, and the other end of the compression spring 11 is fixedly connected with the tight pressing plate 12, and the tight pressing plate 12 is located in the radial direction of the drill bit 7, and the tight pressing plate 12 is also provided with a through hole positioned on the axial direction of the drill bit 7, the through hole is a tapered hole, and the larger end of the tapered hole ...

Embodiment 2

[0026] This embodiment makes the following further limitations on the basis of Embodiment 1: As shown in Figure 1, in order to realize that the motor 1 is far away from the drilling area of the mica plate, it is convenient to clamp and fix the present invention or manually hold and fix, which is beneficial to the rotating shaft. 5 rigidity, also includes the tubular shaft sleeve 2, the shaft sleeve 2 and the rotating shaft 5 gap fit, one end of the shaft sleeve 2 is fixed on the housing of the motor 1, and the compression spring 11 is fixed on the other end of the shaft sleeve 2 Connected to the casing of the motor 1. Preferably, in this structure, the shaft sleeve 2 is embedded with a bearing, that is, the rotating shaft 5 is connected to the shaft sleeve 2 through a bearing. In this embodiment, a fixed seat 3 protruding relative to the shaft sleeve 2 is provided on the shaft sleeve 2 , and the compression spring 11 is connected to the shaft sleeve 2 through the fixed seat ...

Embodiment 3

[0030] This embodiment makes the following further improvements on the basis of any of the above embodiments: figure 1 As shown, in order to avoid indentation caused by excessive local stress on the mica plate when the surface of the mica plate contains granular impurities, a flexible pad is provided on the side of the compact pressing plate 12 away from the motor 1 .

[0031] As a simple and easy-to-process structure, the horizontal tool feed system includes a base 4, a feed roller 10, and a feed table 9, and the feed roller 10 is located in a guide rail arranged on the base 4, and the feed The bottom surface of the table 9 is connected to the feed roller 10;

[0032] The vertical lifting system includes a lifting platform 8 and a brake device for braking the lifting platform 8 to perform lifting movement. The lifting platform 8 is connected to the side of the feeding platform 9 through a dovetail groove, and the motor 1 is fixed on the lifting platform 8 , the braking devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com