Quick precision mold preparation method

A precision mold and fast technology, applied in the field of rapid precision mold preparation, can solve the problems of inability to prepare mold equipment at one time, uneven heating, large shrinkage rate, etc., and achieve good sealing, fast welding speed, and small shrinkage fluctuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

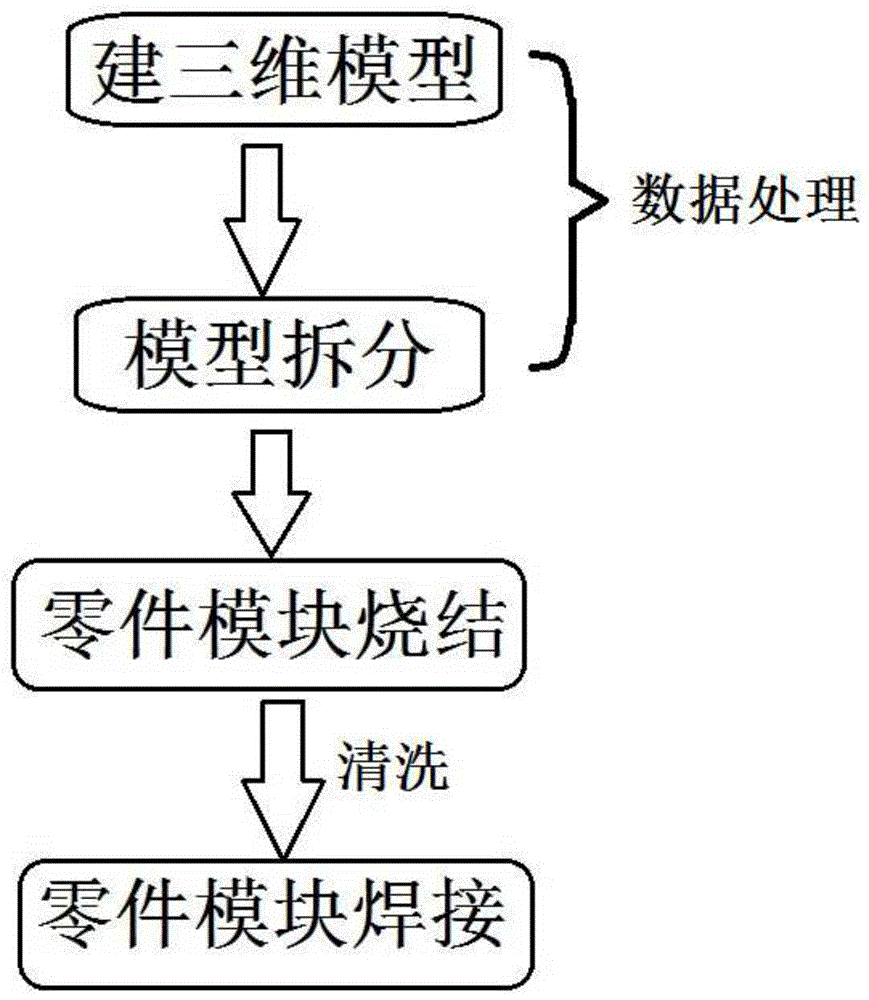

[0016] like figure 1 Shown, the specific embodiment described in the present invention is a kind of rapid precision mold preparation method,

[0017] The first step is to optimize the design of the mold through 3D modeling software, obtain and establish the overall 3D model of the target mold through modeling, and then split the modeled 3D model into multiple smaller structures through 3D modeling Simple part modules, while adding a connection reinforcement structure at the split;

[0018] The second step is to slice the 3D model of each part module, input the sliced data into the industrial computer, and set the process parameters according to the thickness, size, radian and other parameters of different parts, and add polystyrene powder to the In the laser sintering 3D manufacturing machine, the polystyrene powder is evenly spre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com