Electrical stress control hot melting composition and control element provided with hot melting interface

A technology of electrical stress and composition, applied in the installation of electrical components, cable accessories, cables, etc., can solve the problems of inability to meet air gap sealing requirements, failure to meet the reliability of cable accessories, unsatisfactory reliability, etc., to achieve Improved reliability and service life, easy application, and reduced installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

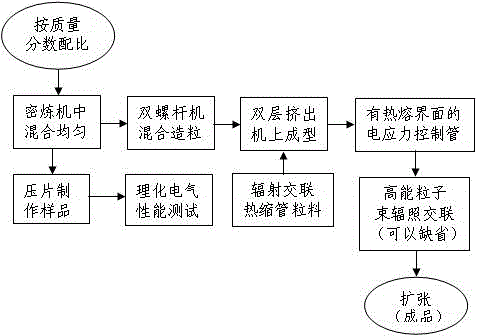

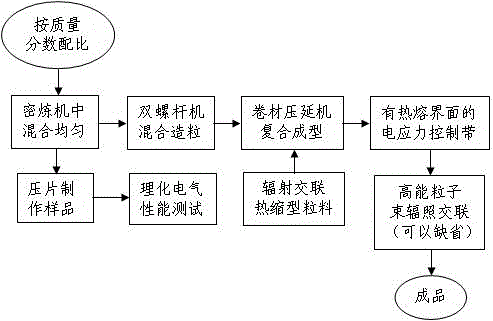

Method used

Image

Examples

Embodiment 1

[0044] Example 1: 100 parts of ethylene-vinyl acetate copolymer (EVA), 20 parts of polyisobutylene, 120 parts of barium titanate, 30 parts of conductive carbon black, and 3 parts of antioxidant "1010".

Embodiment 2

[0045] Example 2: 100 parts of ethylene-vinyl acetate copolymer (EVA), 15 parts of polyisobutylene, 5 parts of terpene resin, 40 parts of barium titanate, 1 part of conductive carbon black, and 1 part of antioxidant "1010".

Embodiment 3

[0046] Example 3: 100 parts of ethylene-vinyl acetate copolymer (EVA), 5 parts of polyisobutylene, 5 parts of terpene resin, 90 parts of barium titanate, 10 parts of barium strontium titanate, 5 parts of conductive carbon black, antioxidant "1010" 1.5 parts, antioxidant "1035" 0.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com