Conductive die-bonding adhesive liquid, conductive die-bonding adhesive film, preparation method and application

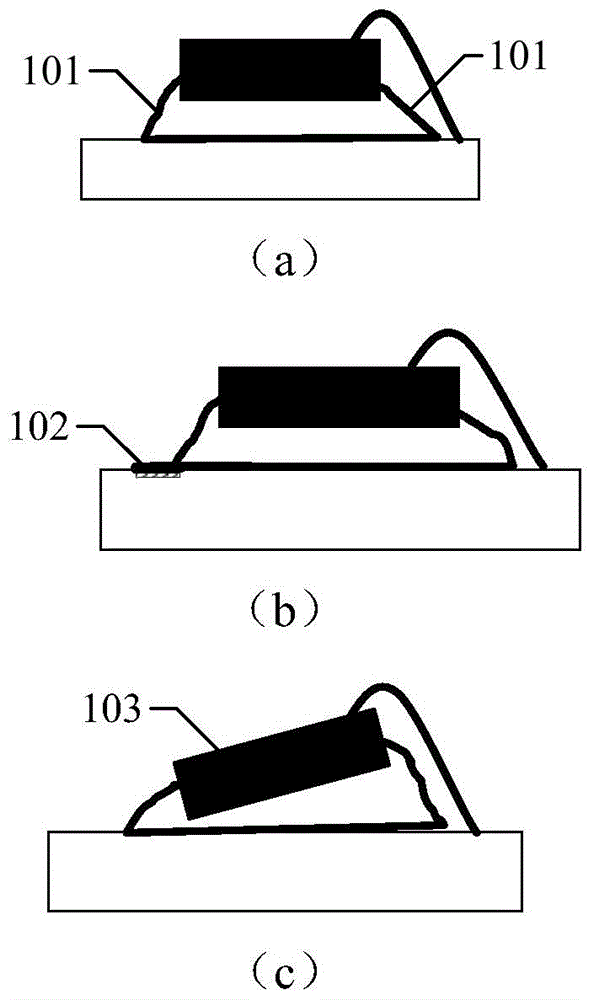

A technology for bonding adhesive films and solid crystals, which is applied in the direction of conductive adhesives, conductive materials dispersed in non-conductive inorganic materials, adhesives, etc., can solve the problems of glue overflow, chip tilting, etc., and achieve thin packaging and good craftsmanship The effect of sex and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

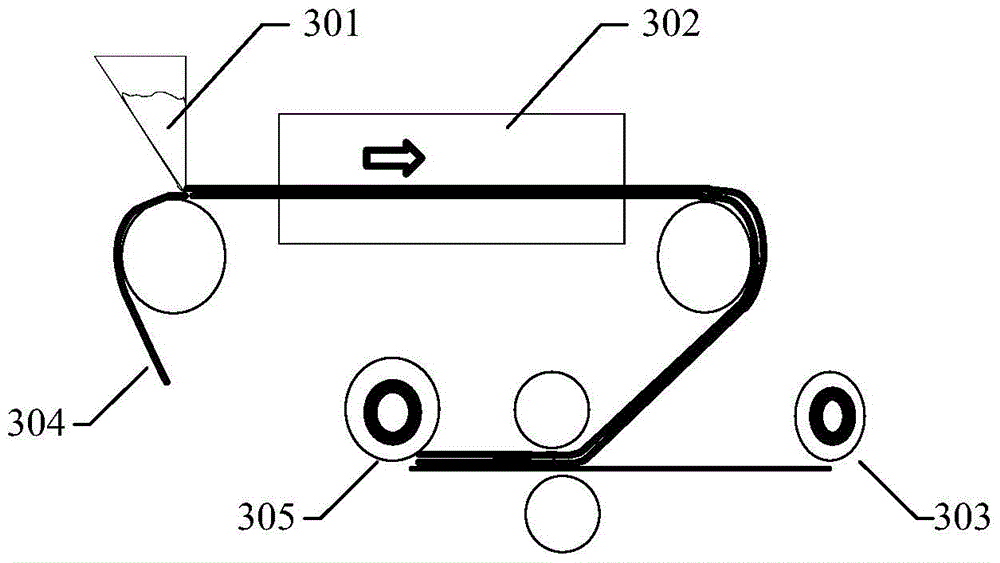

Method used

Image

Examples

preparation example Construction

[0045] The embodiment of the present invention also provides a method for preparing a conductive die-bonding glue, comprising the following steps:

[0046] Step S10: Weigh the raw materials according to the above-mentioned formula of conductive die-bonding glue.

[0047] Step S20: Mix the CTBN modified epoxy resin, the diluent and the thermoplastic resin uniformly at 60-70° C. to obtain a first mixed liquid.

[0048] Step S30: adding the conductive material to the first mixed liquid, mixing evenly and cooling to room temperature to obtain a second mixed liquid. Preferably, the mixing time is preferably 30 to 50 minutes.

[0049] Step S40: Add the curing agent and the coupling agent to the second mixed liquid, mix evenly, then vacuumize, and cool to room temperature to obtain a conductive die-bonding glue.

[0050] The above process can be carried out in equipment such as a reactor, and the whole preparation process can be stirred to make the mixing more uniform.

[0051] Wh...

Embodiment 1

[0062] Table 1 shows the formula of the conductive die-bonding bonding glue in Example 1. Among them, the CTBN modified epoxy resin is prepared by the following process: 40 parts of carboxyl-terminated nitrile rubber CTBN and 60 parts of modified bisphenol A epoxy resin DGEBA are reacted at 120 ° C for 30 minutes to obtain the first mixture, and 2 parts of bisphenol A and 0.08 parts of ethyltriphenylphosphine iodide were added to the first mixture, reacted at 110° C. for 6 h, then vacuumed, and cooled to room temperature to obtain a CTBN modified epoxy resin. Weigh each raw material according to the formula shown in Table 1. Stir and mix the CTBN modified epoxy resin, diluent and thermoplastic resin at 60° C. to obtain a first mixed solution. The conductive material was added to the first mixed solution, mixed for 30 minutes and cooled to room temperature to obtain the second mixed solution. Add the curing agent and the coupling agent to the second mixed solution, stir and m...

Embodiment 2

[0064]The formula of the conductive die-bonding bonding glue in Example 2 is shown in Table 1. Among them, the CTBN modified epoxy resin is prepared by the following process: 10 parts of carboxyl-terminated nitrile rubber CTBN and 40 parts of modified bisphenol A epoxy resin DGEBA are reacted at 110 ° C for 40 minutes to obtain the first mixture, and 1 part of bisphenol A and 0.01 part of ethyltriphenylphosphine iodide were added to the first mixture, reacted at 100°C for 6 hours, then vacuumed, and cooled to room temperature to obtain a CTBN modified epoxy resin. Weigh each raw material according to the formula shown in Table 1. Stir and mix the CTBN modified epoxy resin, the diluent and the thermoplastic resin at 70° C. to obtain a first mixed liquid. The conductive material was added to the first mixed solution, mixed for 50 minutes and cooled to room temperature to obtain the second mixed solution. Add the curing agent and the coupling agent to the second mixed solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com