Method for recovering acetic acid, cobalt and manganese from discharged residues of PTA (purified terephthalic acid) film evaporator

A thin film evaporator, PTA technology, applied in the separation/purification of carboxylic acid compounds, the improvement of process efficiency, organic chemistry, etc., can solve the problems such as the inability to recycle the analytical agent and the large consumption of the analytical agent, and promote further improvement. , The effect of reducing the amount of beating water and operating energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

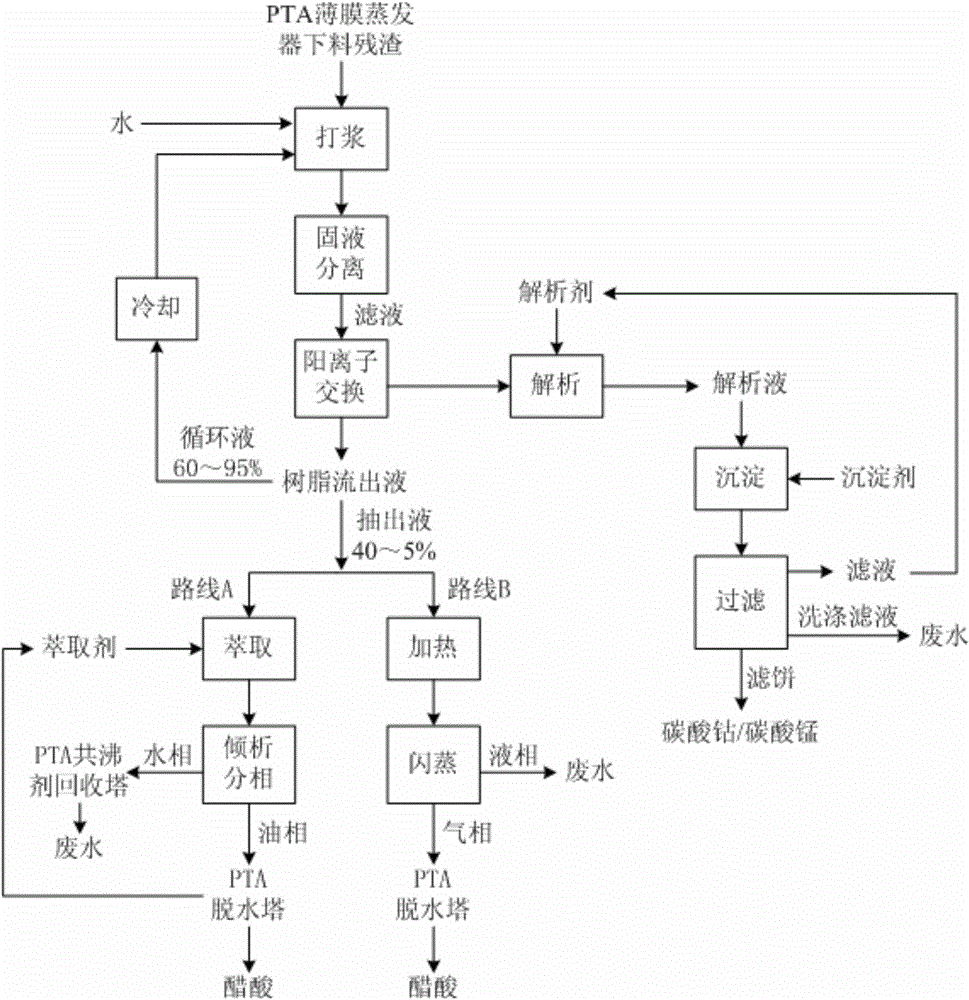

[0036] see figure 1 , the invention provides a method for reclaiming acetic acid and cobalt-manganese ions from the blanking residue of a PTA thin film evaporator. The purpose is to reclaim acetic acid and cobalt-manganese ions in the blanking residue of a PTA thin film evaporator. Manganese, recovery of acetic acid by extraction or evaporation. The method specifically includes the following steps:

[0037](1) Beating: beat the residue of the PTA film evaporator with water to form a residue slurry. The mass ratio of water used for beating to PTA film evaporator blanking residue is preferably 0.2-0.6:1. The thin film evaporator feed residue comes from the thin film evaporator of the oxidation mother liquor impurity removal unit in the terephthalic acid production process. The water used for beating can be demineralized water or industrial water.

[0038] (2) Solid-liquid separation: performing solid-liquid separation on the residue slurry to obtain a raffinate. Preferably,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com