Wind driven generator and method for controlling gear box lubricating and cooling system thereof

A wind turbine, lubrication and cooling technology, applied in the direction of gear lubrication/cooling, wind turbine components, wind turbines, etc., can solve the problem of not being able to meet the heat exchange requirements of the gearbox, so as to improve the heat exchange capacity and increase the heat exchange area , Increase the effect of heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] The invention discloses a 1.5MW wind power generator, which comprises a vertically arranged tower and a wind generator cabin arranged on the tower.

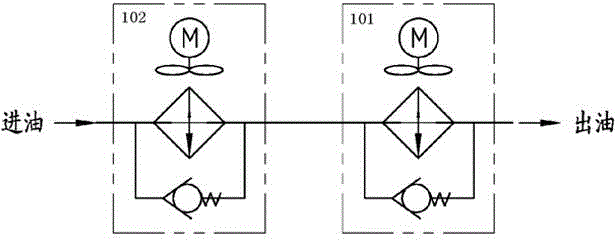

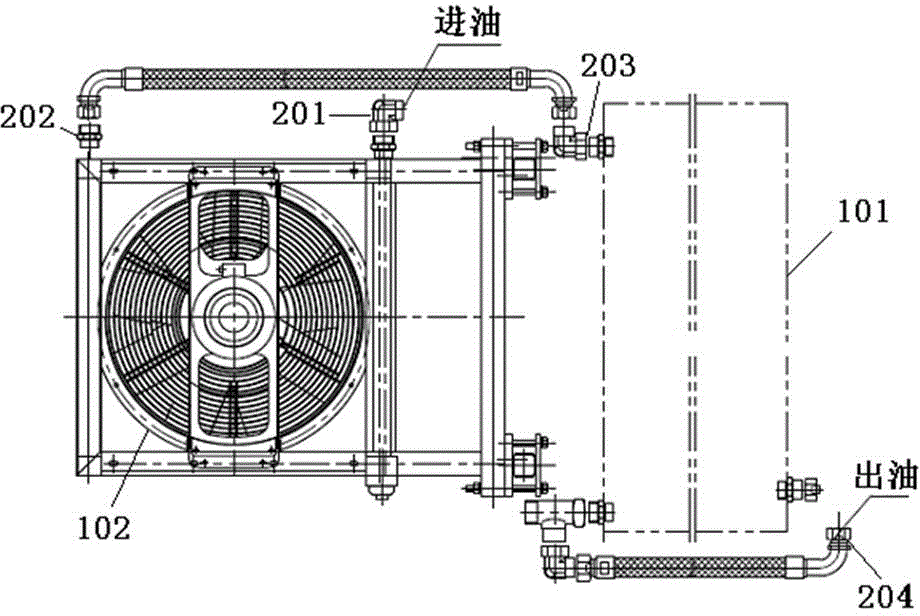

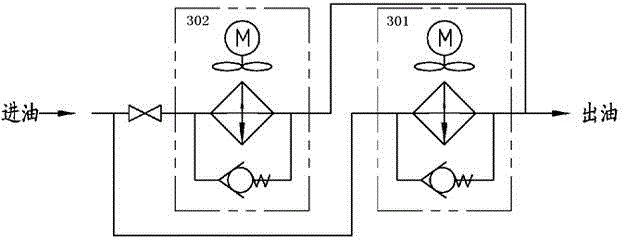

[0034] The wind turbine nacelle is provided with a generator connected to the rotor blades, and a wind turbine gearbox mechanically connected to the output end of the generator. A gearbox lubricating and cooling system is provided on the lubricating oil circuit of the fan gearbox. The gearbox lubricating and cooling system includes a common radiator arranged on the lubricating oil circuit of the fan gearbox. The common radiator is used to reduce the lubricating oil of the fan gearbox temperature to ensure the stable operation of the wind turbine.

[0035] From the analysis of the principle of the lubrication and cooling system of the gearbox of the 1.5MW fan, in order to improve the heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com