A Numerical Control Web Cutting Saw and Its Application

A technology of cross-cut sawing and web cutting, which is applied in the field of CNC web cross-cut sawing, can solve the problems of being unable to meet the needs of paper dealers, unable to cooperate with sawing machines for precise cutting, etc., and achieve good economic value and market value, The effect of wide cutting size range and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

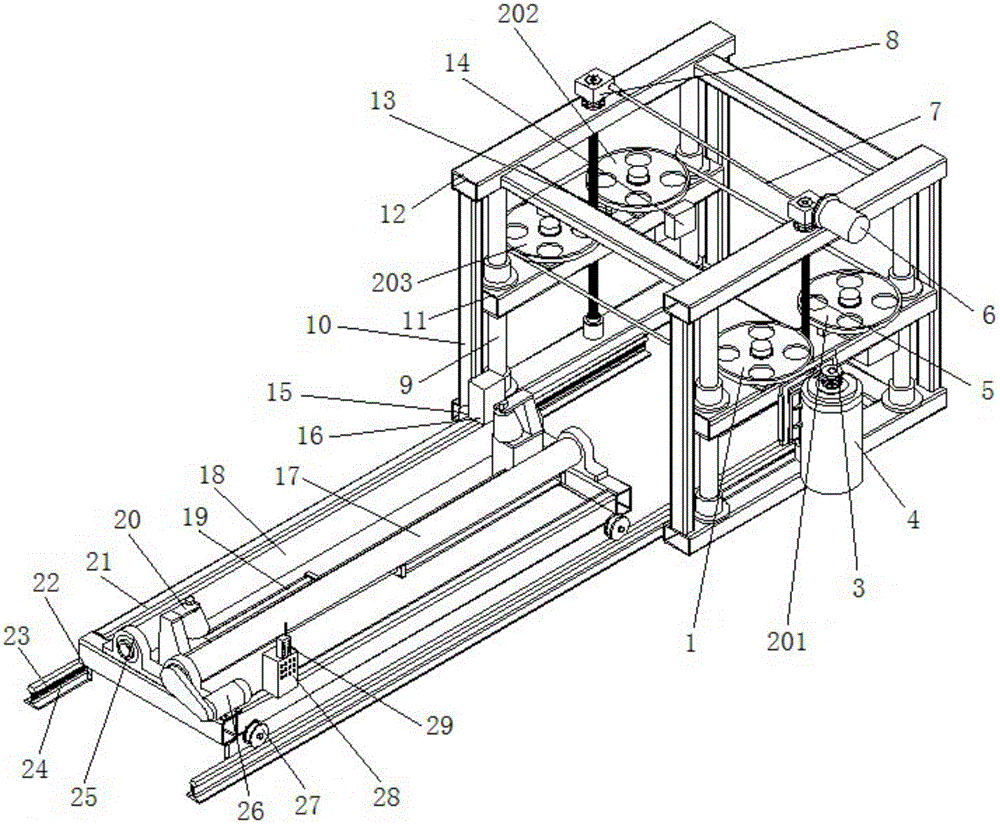

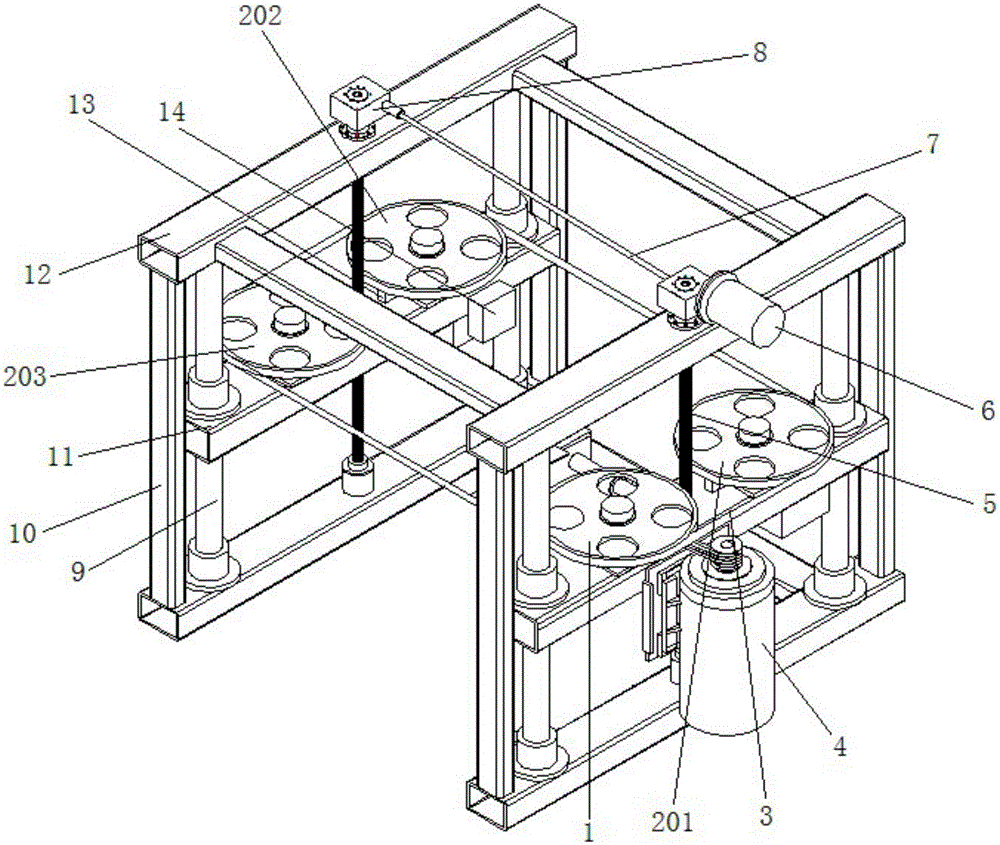

[0035] This embodiment provides a numerically controlled web cross-cutting saw, such as figure 1As shown, it includes a cutting device and a conveying device; the cutting device includes a frame and a sawing mechanism and a lifting mechanism arranged on the frame, and the lifting mechanism is connected with the sawing mechanism to drive the sawing mechanism to move up and down to realize sawing; the conveying The device extends into one side of the frame to feed the product to be cut into the cutting device.

[0036] Wherein, the frame includes four columns 10 and eight connecting beams 12, and the top and bottom ends of the columns 10 are vertically connected to each other by the connecting beams 12 to form a frame frame. Sliding guide posts 9 are arranged symmetrically on both sides of the frame, and there are two sliding guide posts 9 on each side, and the two ends of the sliding guide posts 9 are fixedly installed on the connecting beam.

[0037] The sawing mechanism comp...

Embodiment 2

[0044] This embodiment provides a numerically controlled four-saw wheel cross-cutting saw, the structure of which is as described in Embodiment 1, the difference is that the transport vehicle also includes a hydraulic workstation 16 and a hydraulic clamp 22, which are arranged at the bottom of the vehicle frame The four hydraulic grippers 22 are stretched and contracted through the hydraulic workstation 16. The structural design of the hydraulic gripper 22 includes a hydraulic cylinder, and a C-shaped grip is connected to the bottom end of the piston rod of the hydraulic cylinder. The C-shaped hoop is stuck on the I-shaped guide rail, and the C-shaped hoop is driven by the hydraulic cylinder to clamp the I-shaped guide rail. By setting hydraulic clamps at the four corners of the bottom of the frame, when the frame is loaded with heavy goods, the hydraulic clamps are tightened to make the C-shaped hoop clamp the I-shaped guide rail to improve the vehicle. The stability of the r...

Embodiment 3

[0046] This embodiment provides a numerically controlled web cross-cutting saw, the structure of which is as described in Embodiment 2, and the difference is that the conveying device also includes an electrical control box 28 and a remote controller 29 of the prior art, and the second servo motor 15 and the second drive motor 26 are electrically connected with the electrical control box 28, and the electrical control box 28 is placed on the remote end of the operation or installed on one side of the vehicle frame. By adding an intelligently controlled electrical control box, the moving amount of the conveying vehicle and the rotating speed of the driving roller can be precisely controlled, the cutting accuracy can be improved, and different cutting needs can be met. The remote control 29 can be controlled remotely to keep the operator away from the cutting Work area to ensure personal safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com