Adhesive applied to wood processing and preparation method of adhesive

A technology for adhesives and wood, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor water resistance, poor rheological properties, insufficient bonding strength, etc., and achieve strong water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

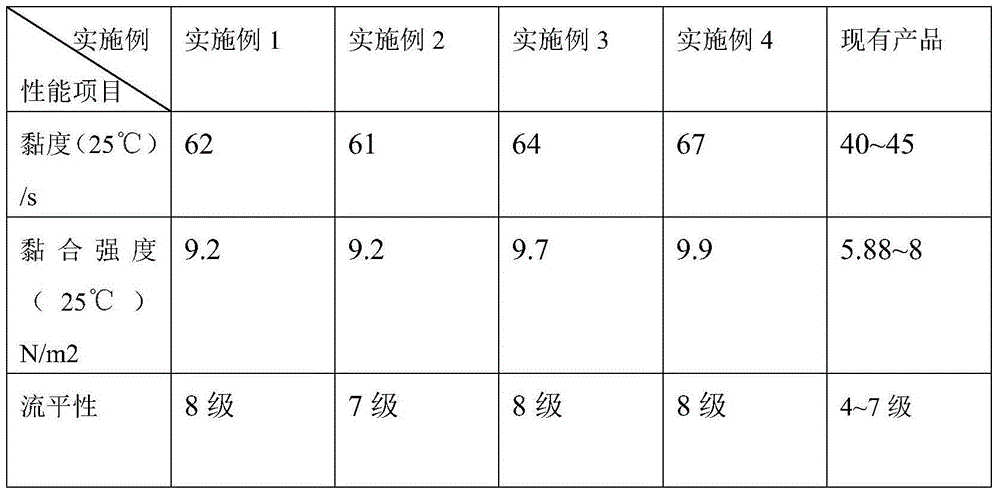

Examples

Embodiment 1

[0032] An adhesive used in wood processing, its components are composed of the following components by weight percentage:

[0033] Starch 100 parts

[0034] 0.2 parts of ferrous sulfate

[0035] Sodium hypochlorite 2 parts

[0036] 13 parts vinyl acetate

[0037] Vinegar-acrylic emulsion 13 parts

[0038] Tributyl phosphate 0.1 parts

[0039] Functional molecules 5.5 parts

[0040] Fumed silica 6 parts

[0041] 40% sodium hydroxide solution 29 parts

[0042] 200 parts of water.

[0043] The above-mentioned preparation method of an adhesive applied to wood processing, the preparation steps of the described adhesive applied to wood processing are:

[0044] Refining of S1 starch

[0045] S1.1 After mixing the starch and water evenly, adjust the pH to 8-9 with sodium hydroxide solution and let it stand for 20-30 hours, then heat and dry at 80-90°C and grind it finely for later use;

[0046] Preparation of S2 oxidized starch

[0047] S2.1 Add the ground starch into water...

Embodiment 2

[0052] An adhesive used in wood processing, its components are composed of the following components by weight percentage:

[0053] Starch 100 parts

[0054] 0.4 parts of ferrous sulfate

[0055] Sodium hypochlorite 5 parts

[0056] 10 parts vinyl acetate

[0057] Vinegar-acrylic emulsion 8 parts

[0058] Tributyl phosphate 0.05 part

[0059] Functional molecules 3.7 parts

[0060] Fumed silica 2 parts

[0061] 25 parts of 40% sodium hydroxide solution

[0062] 100 parts of water.

[0063] The above-mentioned preparation method of an adhesive applied to wood processing, the preparation steps of the described adhesive applied to wood processing are:

[0064] Refining of S1 starch

[0065] S1.1 After mixing the starch and water evenly, adjust the pH to 8-9 with sodium hydroxide solution and let it stand for 20-30 hours, then heat and dry at 80-90°C and grind it finely for later use;

[0066] Preparation of S2 oxidized starch

[0067] S2.1 Add the ground starch into wat...

Embodiment 3

[0072] An adhesive used in wood processing, its components are composed of the following components by weight percentage:

[0073] Starch 100 parts

[0074] 0.3 parts of ferrous sulfate

[0075] Sodium hypochlorite 3 parts

[0076] Vinyl acetate 11 parts

[0077] Vinegar-acrylic emulsion 11 parts

[0078] Tributyl phosphate 0.09 parts

[0079] Functional molecules 4.8 parts

[0080] Fumed silica 4 parts

[0081] 27 parts of 40% sodium hydroxide solution

[0082] 180 parts of water.

[0083] The above-mentioned preparation method of an adhesive applied to wood processing, the preparation steps are:

[0084] 6. The preparation steps of the adhesive are:

[0085] Refining of S1 starch

[0086]S1.1 After mixing the starch and water evenly, adjust the pH to 8-9 with sodium hydroxide solution and let it stand for 20-30 hours, then heat and dry at 80-90°C and grind it finely for later use;

[0087] Preparation of S2 oxidized starch

[0088] S2.1 Add the ground starch into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com