Method for reducing component loss and formation damage in high-temperature combined chemical flooding process

A technology of combined oil displacement and high temperature chemistry, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problem of not being able to effectively meet the start-up residual oil, unable to guarantee the deep oil displacement effect of the reservoir, and not disclosed Compatibility of organic bases with polymers and surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] Step 2 measurement result is:

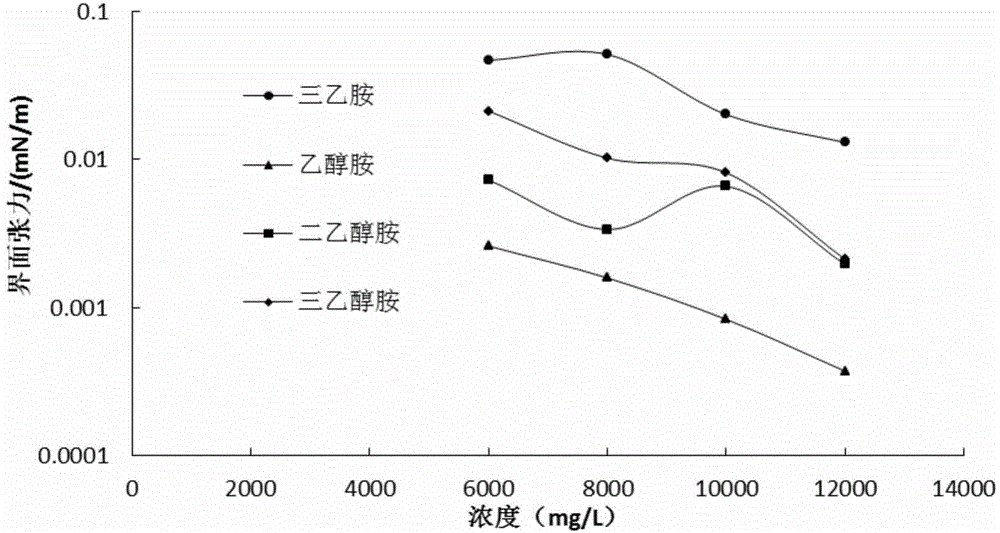

[0130] The dynamic curves of oil-water interfacial tension under different concentrations of triethylamine and ethanolamine, diethanolamine, and triethanolamine are as follows: figure 1 .

[0131] From the dynamic curve of interfacial tension, it can be seen that after the compounding of triethylamine and surfactant, it is still 10 -2 On the order of mN / m, ultra-low interfacial tension cannot be achieved, while ethanolamine obviously reaches 10 -3 On the order of mN / m, although the oil-water interfacial tension of the diethanolamine and triethanolamine compound system is not as low as that of ethanolamine, it can still reach 10 -3 mN / m. Therefore, ethanolamine, diethanolamine, and triethanolamine can be selected for key investigation.

Embodiment 2

[0133] Step 3 measurement result is:

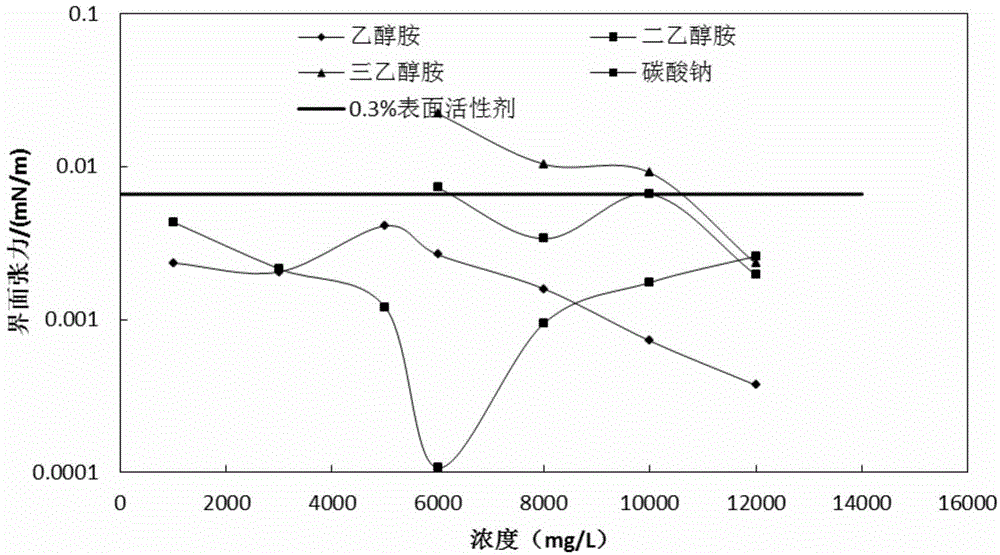

[0134] Comparison example of three kinds of organic bases with different concentrations of ethanolamine, diethanolamine and triethanolamine and weak base sodium carbonate to reduce interfacial tension figure 2 . figure 2 The middle black line represents the oil-water interfacial tension of 3000mg / L surfactant single agent 6.61×10 -3 mN / m.

[0135] It can be seen that the oil-water interfacial tension value of the 3000mg / L active agent SH-6 solution without alkali is 6.61×10 -3mN / m, the addition of three organic bases can improve the interfacial tension to varying degrees, among which ethanolamine has the most obvious effect, and the interfacial tension can be reduced in the concentration range of 1000mg / L-12000mg / L. After the concentration is greater than 8000mg / L, The interfacial tension was reduced to 10 -4 mN / m order of magnitude; only when the concentration of diethanolamine is greater than 8000mg / L and the concentration of trie...

Embodiment 3

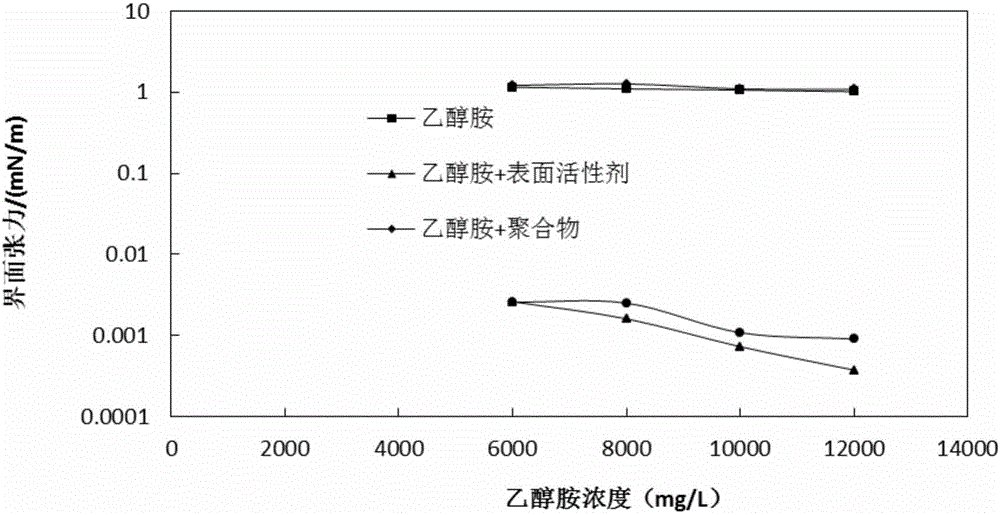

[0137] Step 4 measurement result is:

[0138] The comparison of the properties of the three organic bases ethanolamine, diethanolamine and triethanolamine is shown in Table 1.

[0139] Ethanolamine has the best solubility, is miscible with water, and has the lowest cost. Compared with other physical and chemical properties, the three organic bases have little difference. Based on the interfacial tension and the above properties, ethanolamine was selected as an organic base to form a chemical flooding composite system with surfactants and polymers, and its interfacial tension, alkali consumption and formation damage were further systematically evaluated.

[0140] Table 1 Comparison of three kinds of organic alkali properties

[0141]

[0142]

[0143]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com