Magnetic compensation coil structural component for miniature nuclear magnetic resonance gyroscope

A technology of nuclear magnetic resonance gyroscope and compensation coil, which is applied in the direction of steering induction equipment, etc., can solve the problems of difficult installation of square Helmertz coils, poor uniformity of magnetic field, and deterioration of uniformity, and achieve simple and reliable positioning methods and uniform longitudinal static magnetic field , The effect of high preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

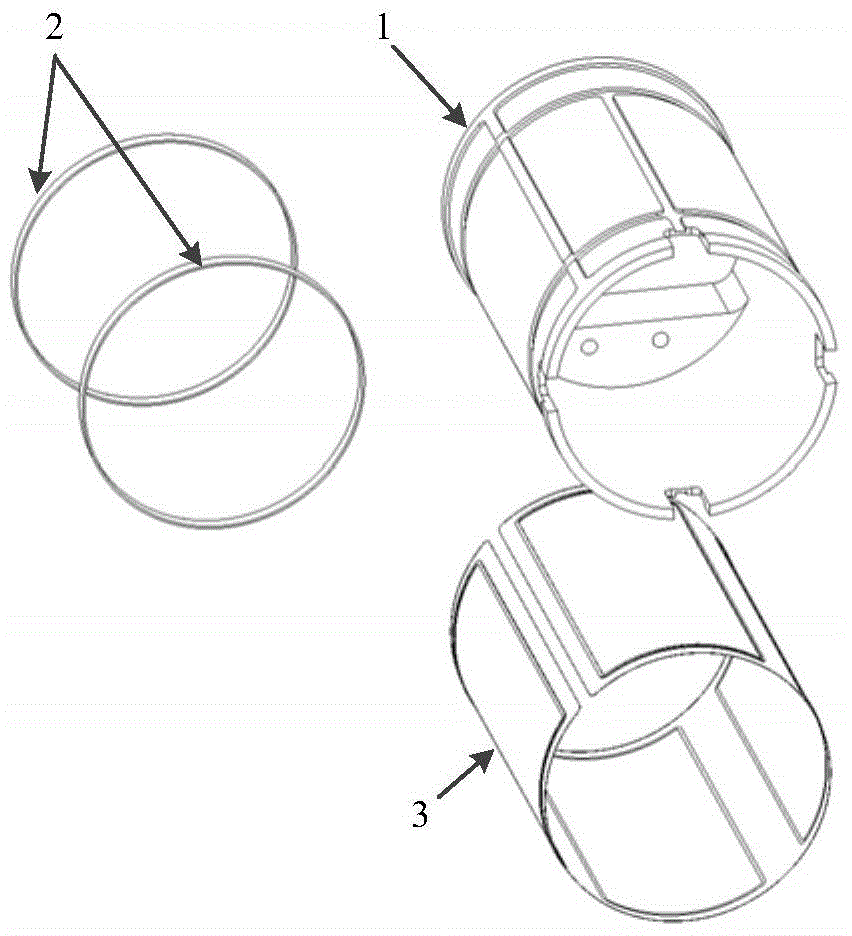

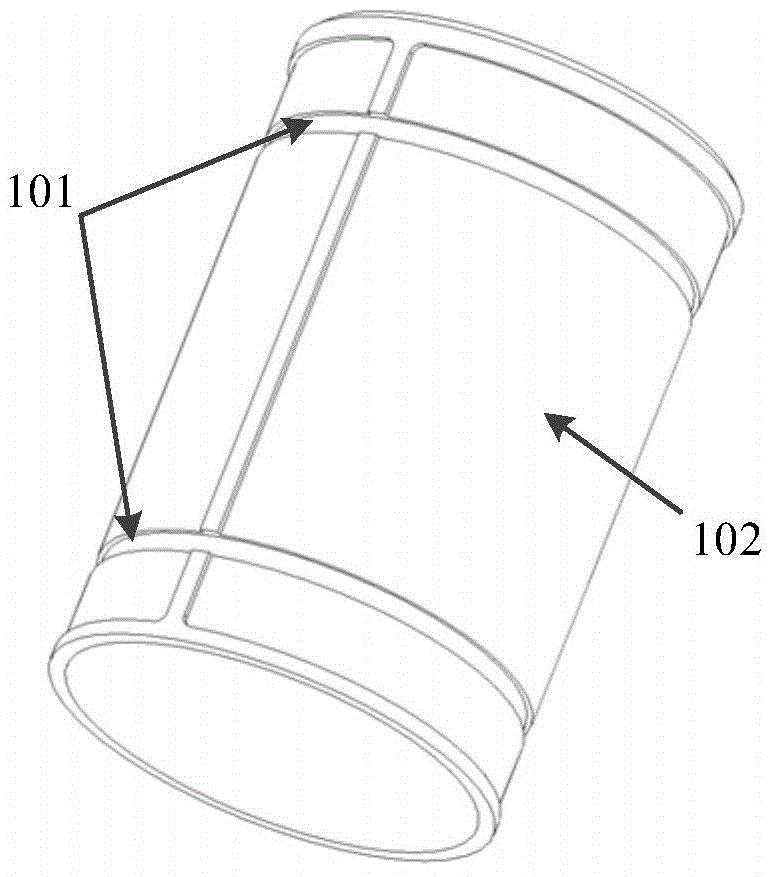

[0032] In the magnetic compensation coil structure used for the miniature nuclear magnetic resonance gyroscope of the present invention, the mandrel support adopts polyimide, the thermal conductivity is 9.2W / (m.°C), the continuous heat-resistant temperature is 250°C, and the structure is Cylindrical, set outside the optical path structure of the atomic gas chamber, without interfering with the optical path structure.

[0033] The longitudinal magnetic compensation coil adopts a circular Helmertz coil structure, the coil diameter is 33mm, and the distance between the two ring coils is 33mm. Among them, the enameled wire with a diameter of 0.1mm is wound in the winding groove of the mandrel support, and each group of coils With 50 turns and excitation current of 0.01A, a longitudinal magnetic field of ~13μT can be generated, and the uniformity of the magnetic field is better than 1%.

[0034]The transverse magnetic compensation coil adopts 4 sets of saddle-shaped coils. The diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com