Alignment layer detecting device and method

A technology of detection device and orientation film, which is applied to measurement devices, image data processing, instruments, etc., can solve the problems of reducing the utilization rate of production lines, affecting the process, consuming a lot of manpower and material resources, and improving detection efficiency and detection conditions. The effect of low requirements and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

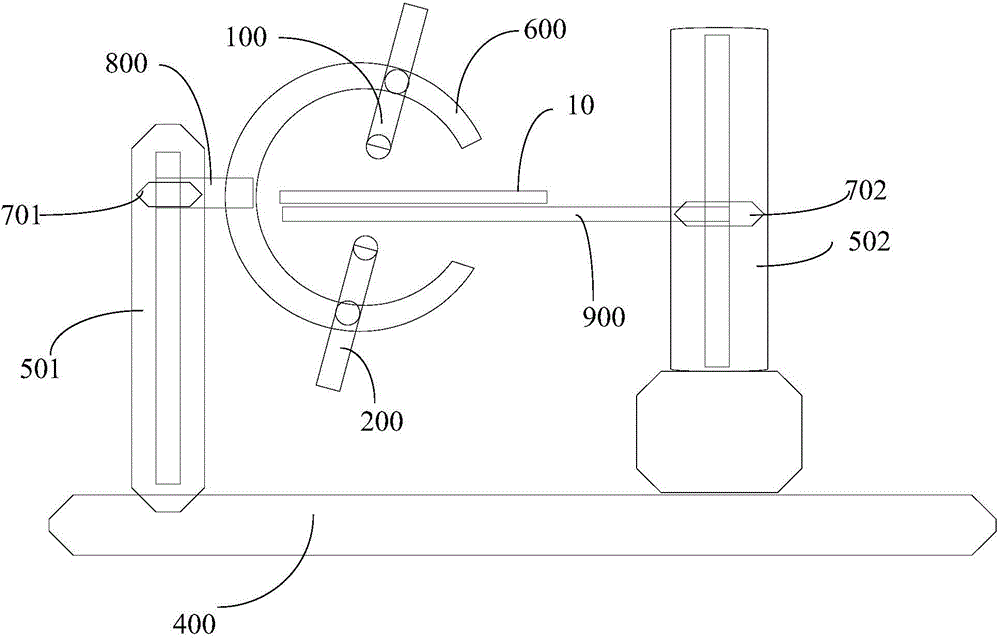

[0059] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0060] Aiming at the problems of low detection efficiency and poor accuracy in detecting the defects of the alignment film of the substrate in the prior art, the present invention provides an alignment film detection device for detecting the alignment grooves formed on the alignment film of the substrate. The slot is used for detection, which can improve the detection efficiency and the accuracy and reliability of the detection results.

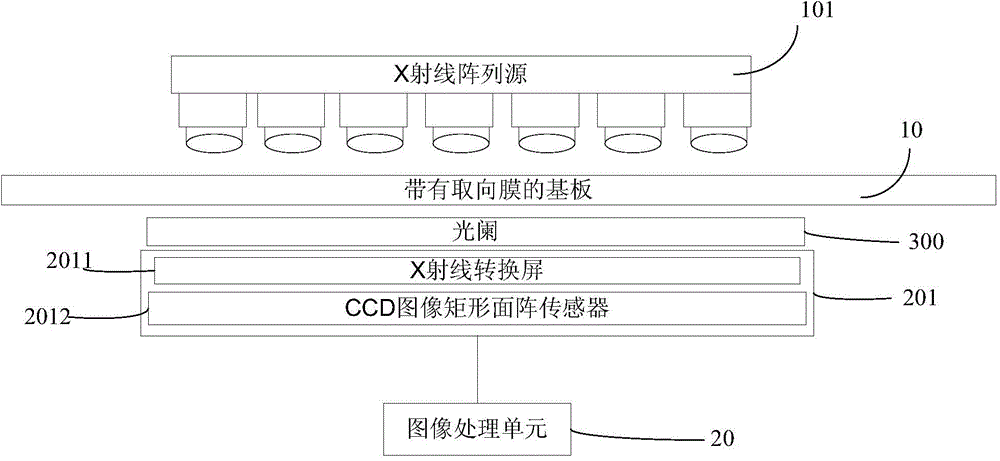

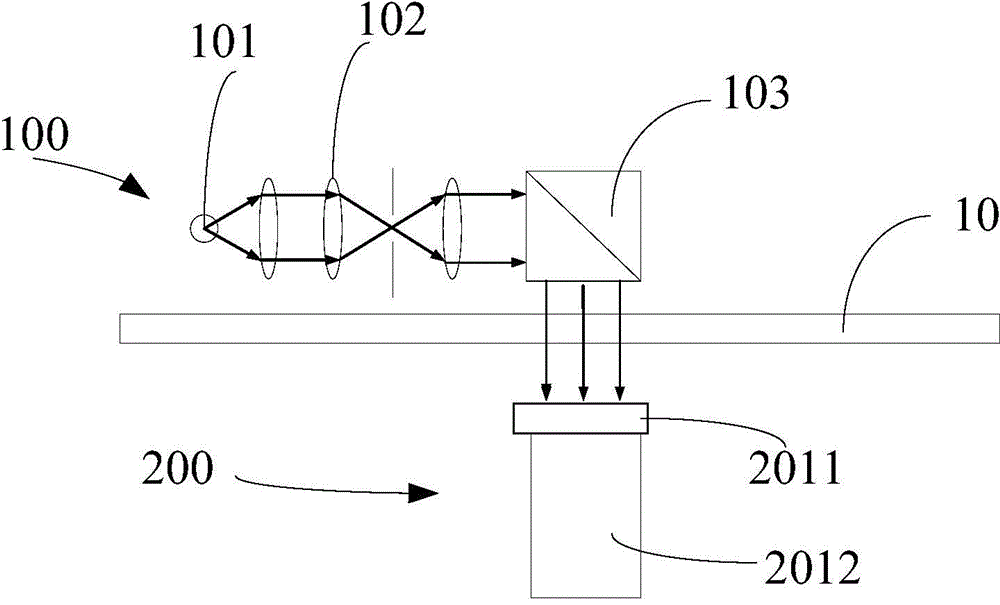

[0061] Such as Figure 1 to Figure 3 As shown, the alignment film detection device provided by the present invention includes:

[0062] an image imaging unit for acquiring image information of alignment grooves on the alignment film of the substrate 10;

[0063] And, an image pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com