Method used for preparing pig feed by taking sweet potato vine as raw material

A sweet potato seedling, pig feed technology, applied in animal feed, animal feed, application and other directions, can solve problems such as poisoning, low digestion and absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Ingredients according to the following parts by weight: 70 sweet potato seedlings, 30 corn, multidimensional 0.1, biological fattening essence 0.15, baking soda powder 0.5, saccharin 0.012 grams, fermented yeast liquid 0.008; Acid lactic acid bacteria: Bacillus subtilis = 90:4:1; sweet potato seedlings are crushed into diameters of 6-33mm;

[0018] The water content is controlled to 60 wt%, the temperature is above 0° C., and the sealed fermentation is carried out for 60 hours to obtain fermented sweet potato seedling pig feed.

Embodiment 2

[0020] Ingredients according to the following parts by weight: 80 sweet potato seedlings, 20 corn, 0.3 multidimensional, 0.05 biological fattening essence, 1.5 baking soda powder, 0.008 grams of saccharin, 0.012 grams of fermented yeast liquid; Acid lactic acid bacteria: Bacillus subtilis = 100:2:1;

[0021] The water content is controlled to 70 wt%, the temperature is above 0° C., and sealed fermentation is carried out for 84 hours to obtain fermented sweet potato seedling pig feed.

Embodiment 3

[0023] Ingredients according to the following parts by weight: 75 sweet potato seedlings, 25 corn, multidimensional 0.2, biological fattening essence 0.1, baking soda powder 1, saccharin 0.01 g, fermented yeast liquid 0.01; Acid lactic acid bacteria: Bacillus subtilis = 96:3:1.

[0024] The water content is controlled at 65 wt%, the temperature is above 15° C., and sealed fermentation is carried out for 72 hours to obtain fermented sweet potato seedling pig feed.

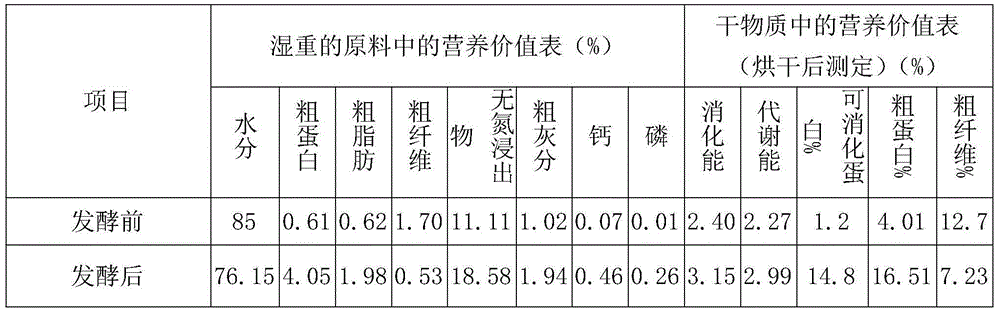

[0025] The raw material of sweet potato seedlings before and after fermentation in Example 3 was tested and analyzed for wet weight and dried nutritional value, and the results are shown in Table 1.

[0026] Table 1

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com