Fast growing wood decorative plate manufacturing method

A manufacturing method and technology of fast-growing wood, which are applied in special decorative structures, processes for producing decorative surface effects, decorative arts, etc., can solve the problem of difficult maintenance, difficult to clean up, and inability to make good use of ordinary inferior wood and fast-growing wood. materials, etc., to achieve good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

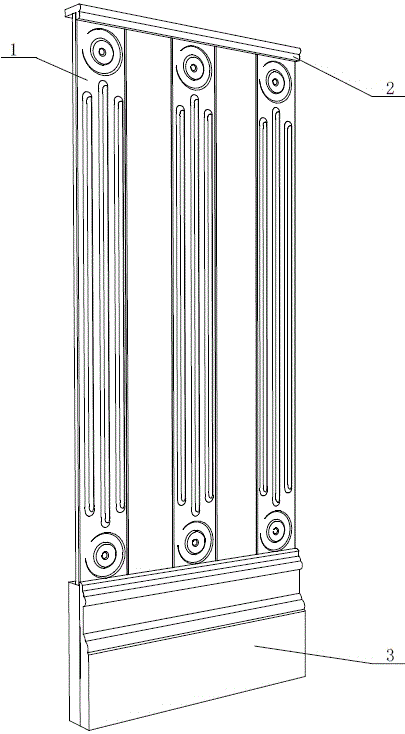

Image

Examples

specific Embodiment approach 1

[0029] Embodiment 1: The manufacturing method of the two-dimensional three-dimensional wooden interior decoration wall hanging board described in this embodiment includes the following steps:

[0030] Step 1, the described retaining board adopts timber slab as raw material, and the moisture content of this raw material is 6%-15%;

[0031] Step 2. According to the wall specifications and design modulus of the interior space to be decorated, the raw materials are processed and finished with fixed thickness, fixed length and fixed width;

[0032] Step 3. Compare the two board surfaces corresponding to the raw materials, select the side with clear and uniform wood texture, no or less scarring, no blunt edges, no moth-eaten defects and no corrosion as the front side, and choose the other side as the back side ;Milling stress balance grooves on the back of the raw material;

[0033] Step 4, by means of a two-dimensional three-dimensional modeling method, make a two-dimensional thre...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and the method for manufacturing two-dimensional three-dimensional wooden interior decorative wall hanging panels described in Embodiment 1 is that the two-dimensional modeling method described in step 4 uses drawing, printing, and smearing. , hot stamping or spraying.

[0039] In the manufacturing process, the pattern on the surface of the two-dimensional three-dimensional wooden interior decoration wall hanging board can be geometric shapes, characters, animals, plants and flowers, natural scenery, graphic outlines and light and shadows of buildings or building parts, and different textures and shades in the patterns Different levels of color can represent different ups and downs. When the pattern is a monochrome pattern, the blank part represents protrusion or light receiving, and the dark part of the pattern represents depression, backlight or projection.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and the two-dimensional three-dimensional wooden interior decoration wall hanging board manufacturing method described in Embodiment 1 is that the specific process of finishing described in Step 2 is: use 80 mesh to 180 mesh sandpaper Carry out sanding on the surface of the raw material to make the surface of the raw material smooth and free of burrs, oil stains and other surface pollutants, so that the saw edge is free of stubble.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com