Injection molded leather sole and making method thereof

A manufacturing method and a technology for leather shoes are applied in the field of leather soles to achieve the effects of simple and practical production process, high physical property index and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

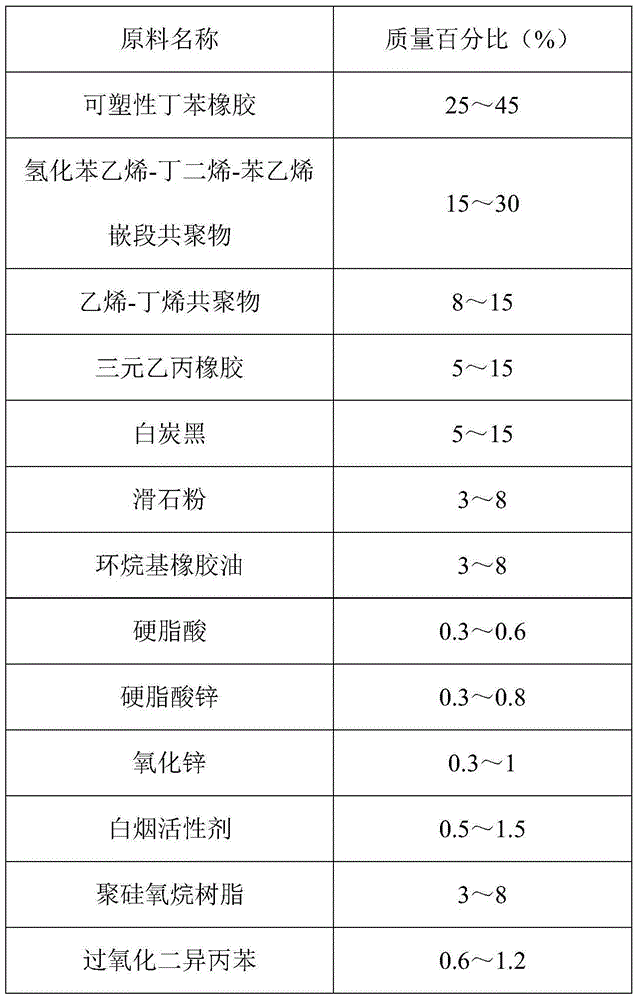

Method used

Image

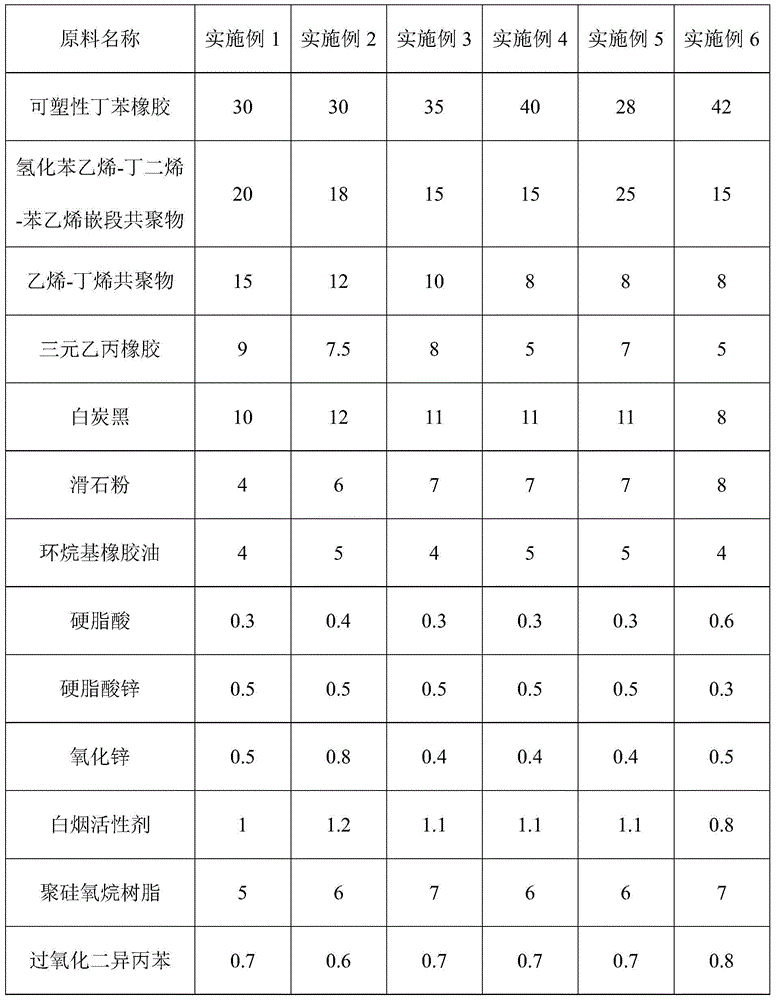

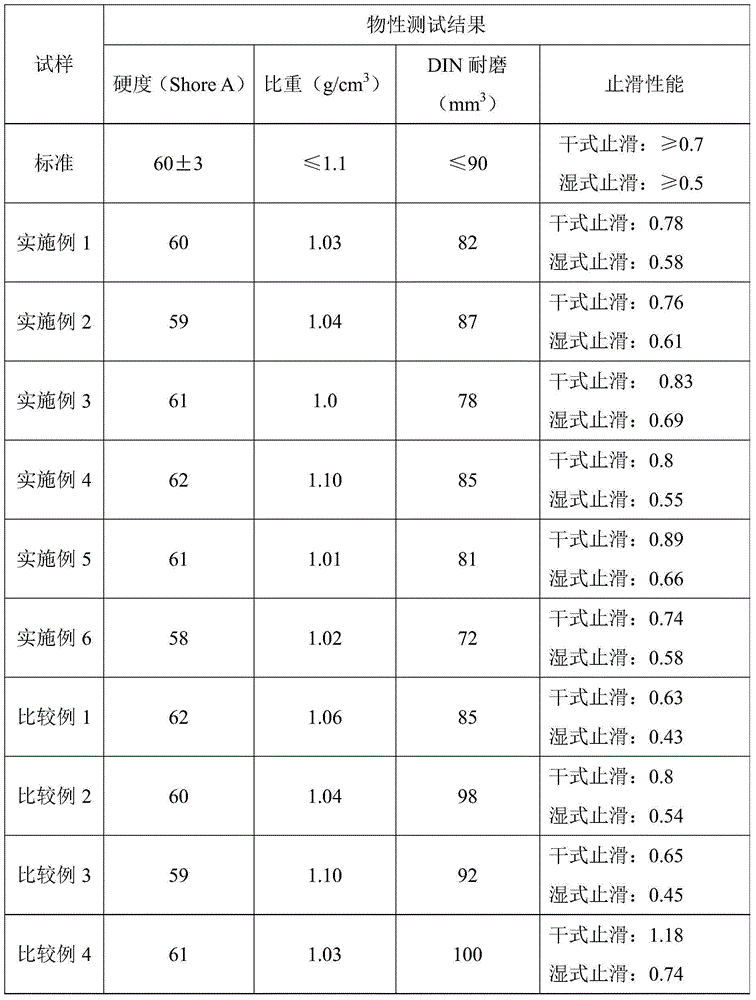

Examples

Embodiment Construction

[0035] The following examples will further illustrate the present invention.

[0036] The raw materials in the formula can choose the product grades produced by the following companies:

[0037] The plastic styrene-butadiene rubber adopts the plastic styrene-butadiene rubber (TVA) jointly developed by Sinopec Baling Petrochemical Company and Sichuan University; the ethylene-butene copolymer is POE168 produced by Korea LG Company; EPDM3722P produced by Dow Company; hydrogenated styrene-butadiene-styrene block copolymer (SEBS) is produced by Jiangsu Top Plastic Industry Co., Ltd.; polysiloxane resin is polysiloxane resin produced by Dow Corning Corporation of the United States; Naphthenic rubber oil adopts KN4006 produced by China Petroleum Lubricating Oil Company; white carbon black can adopt white carbon black JS-160 provided by Fujian Shaxian Jinsha Silica Manufacturing Co., Ltd., and its chemical name is precipitated hydrated silica; The smoke active agent is white smoke ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com