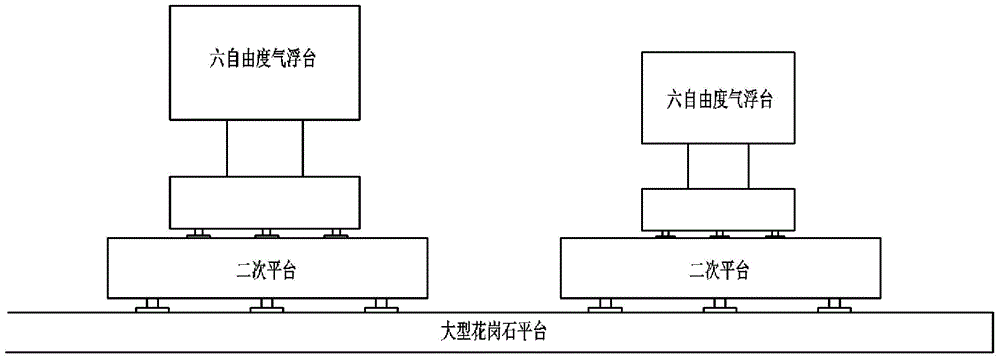

Pressure air supply system

A pressure and gas source technology, which is applied in the field of air flotation gravity unloading simulation test, can solve the problems of large storage space occupied by gas cylinders, bursting of gas storage tanks, casualties, etc., and achieves increased equipment investment, convenient gas source supply, and improved safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

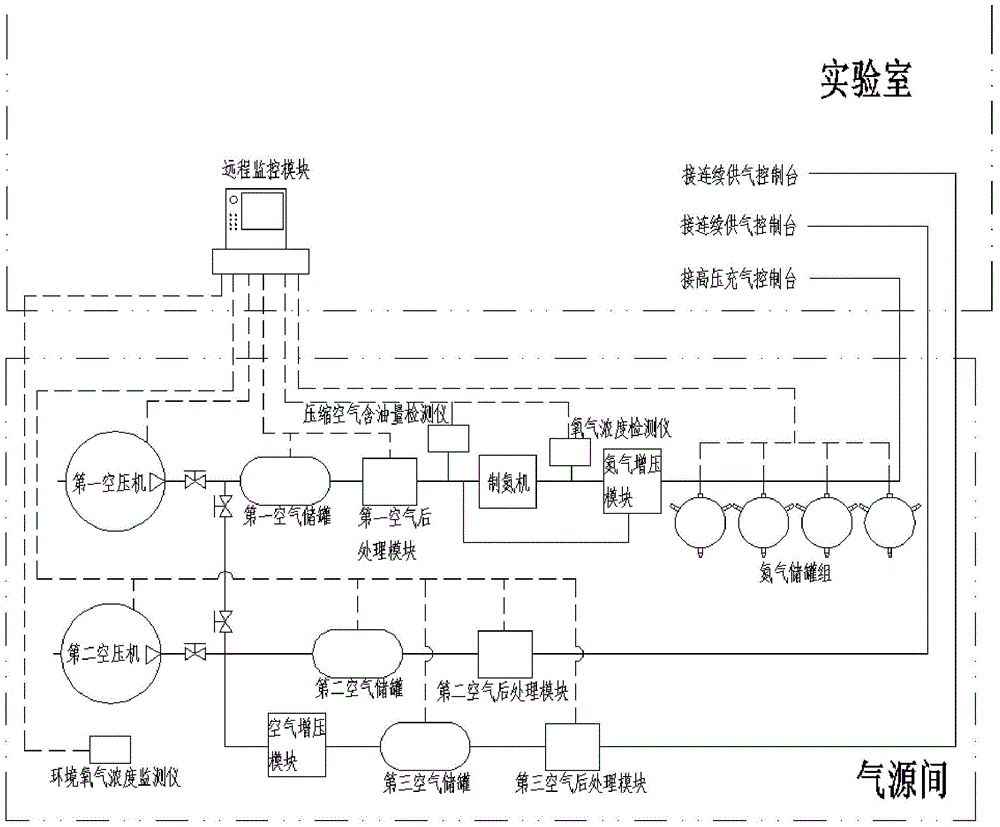

[0036] (1) Both the first air compressor and the second air compressor are air-cooled screw air compressors, the output pressure is 1.0MPa, and the output flow rate is 17.5m 3 / min; the output of the two air compressors is connected through one pressure pipeline, and connected to the other subsystem through the switch combination of four shut-off valves (see attached figure 2 ) are mutual backups.

[0037] (2) The output of the second air compressor is divided into two paths; one path is directly output as a 1MPa air source; one path splits a part of the flow as driving air to drive the air booster module to pressurize the other part of the compressed air output as a 2MPa air source, due to part of the flow Used as driving gas, the flow rate of 2MPa gas source is only 10m 3 / min, but it has met the requirements of use; the air booster module adopts full mechanical piston booster technology, and the output flow rate is 12m 3 / min, the output pressure is 2.0MPa.

[0038] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com