Producing method of intermittent-filling fracture rock sample model

A production method and technology for rock samples, which are applied in the preparation of test samples and other directions, can solve the problem of inability to effectively produce intermittently filled fracture rock sample models, and achieve the effects of meeting the needs of sample preparation, low price and convenient purchase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

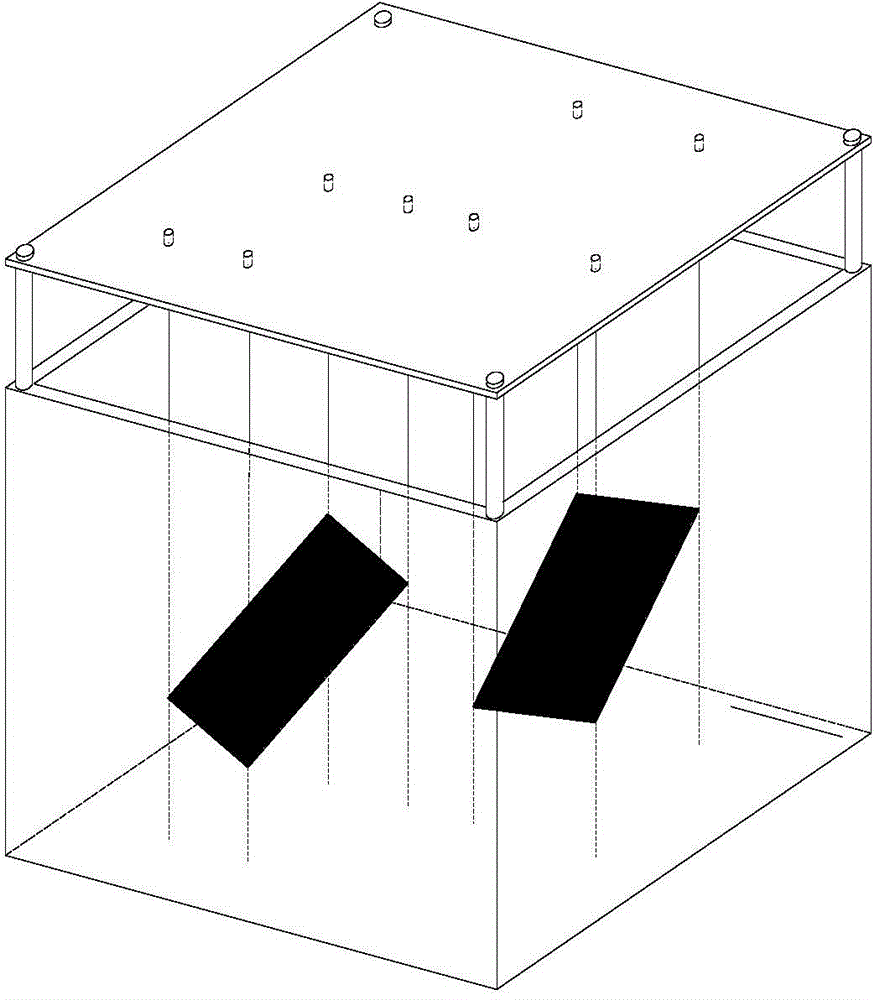

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

[0041] refer to figure 1 , a method for making a rock sample model for intermittently filling a fracture, comprising the steps of:

[0042] Material preparation and parameter determination:

[0043] Statistically investigate the fracture development characteristics in the rock samples in the study area, measure the gap width, inclination, dip angle, and extension range of rock mass fractures per unit volume by line survey or drilling method, judge the filling type of structural planes, and select typical rock mass fractures. Blocks and fracture fillings were sampled separately.

[0044] Determination of physical and mechanical properties of rock blocks, including density, saturated water content, compressive strength, elastic modulus, flexural strength and softening coefficient. Determine the material composition of the fissure filling material, and judge its basic ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com