A Hot Stage for Small Angle Scattering Experiments

A small-angle scattering and experimental technology, used in material analysis, measurement devices, instruments, etc. using wave/particle radiation, which can solve problems such as hindering neutrons, X-ray transmission, inability to use neutrons, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

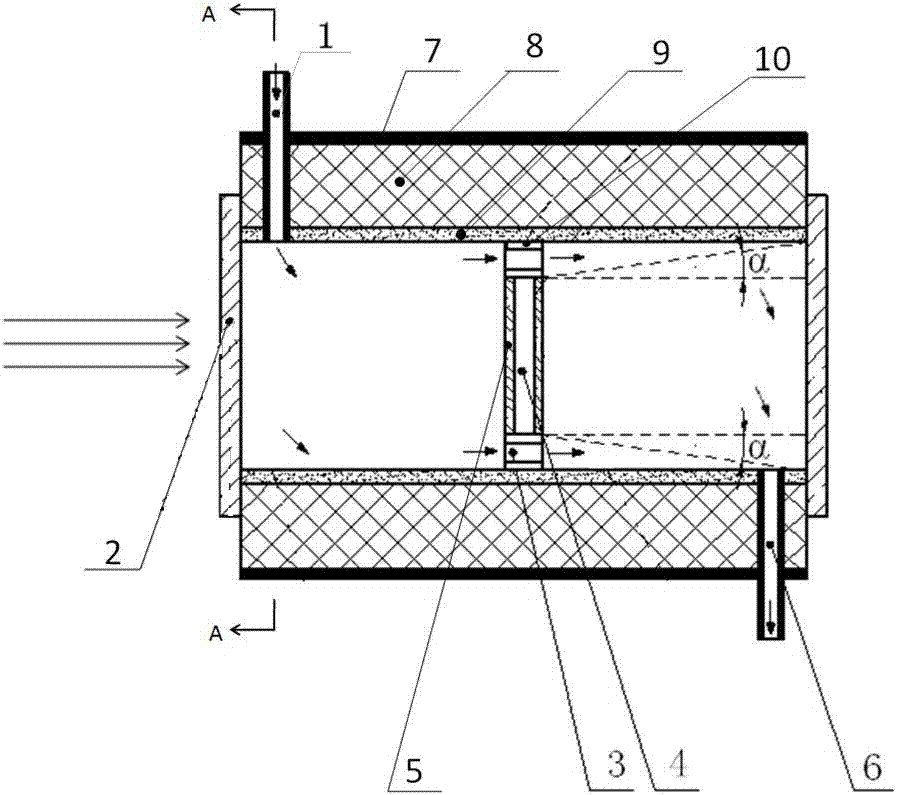

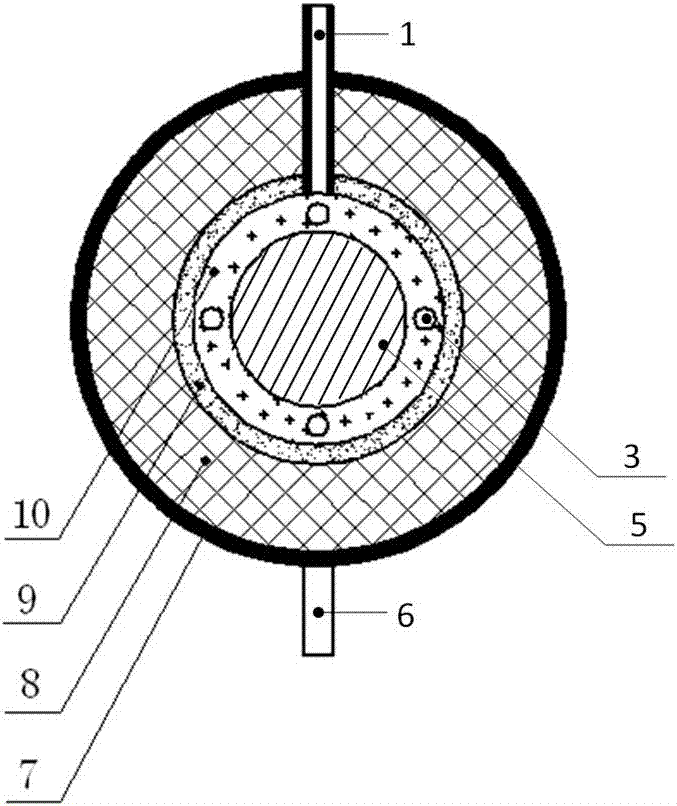

[0024] figure 1 It is the cross-sectional view of the hot stage used for the small angle scattering experiment of the present invention, figure 2 for figure 1 A-A partial cross-sectional view in. exist figure 1 , figure 2 Among them, a kind of hot stage used for small angle scattering experiment of the present invention contains air inlet channel 1, sealing window 2, light-transmitting window 5, exhaust channel 6, heating layer encapsulation wall 7, heating layer 8, sample chamber 9, sample The fixture layer 10, its connection relationship is that the heating stage is cylindrical, and the annular sample fixture layer 10, the sample chamber 9, the heating layer 8, and the heating layer packaging wall 7 are sequentially arranged on the central axis from the inside to the outside. . The two ends of the sample chamber 9 are respectively equipped with sealing windows 2, and are connected with the sealing windows 2 by bolts to form a closed body. The sample holder layer 10 i...

Embodiment 2

[0030] The structure of this embodiment is the same as that of Embodiment 1. The difference is that the material of the sample chamber and the sample holder layer is silicon carbide ceramics, the material of the sealing window is sapphire, the material of the light-transmitting window is sapphire, the material of the heating layer packaging wall is silicon carbide ceramics, and iron-chromium-aluminum alloy is used. The electric heating wire is used as a heating layer, and eight air holes are provided.

Embodiment 3

[0032] The structure of this embodiment is the same as that of Embodiment 1. The difference is that the material of the sample chamber and the sample holder layer is silicon carbide ceramics, the material of the sealing window is Kapton film, the material of the light-transmitting window is Kapton film, the material of the heating layer packaging wall is silicon carbide ceramics, and nickel-chromium is used. Alloy heating wire is used as the heating layer, and the air holes are set to thirty-two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com