Laser eutectic soldering device and method

A eutectic welding and laser technology, used in laser welding equipment, welding equipment, printed circuits, etc., can solve problems such as low temperature, circuit metal loss, adhesion, etc., to ensure accuracy, ensure uniformity and accuracy, and adjust real-time adjustment. fast temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention is described in detail below in conjunction with accompanying drawing:

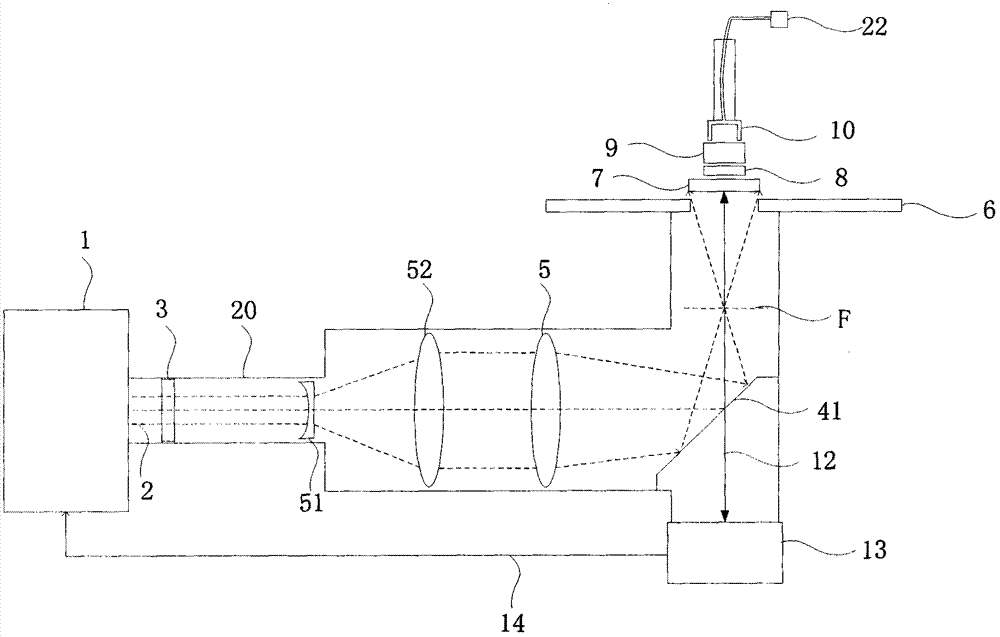

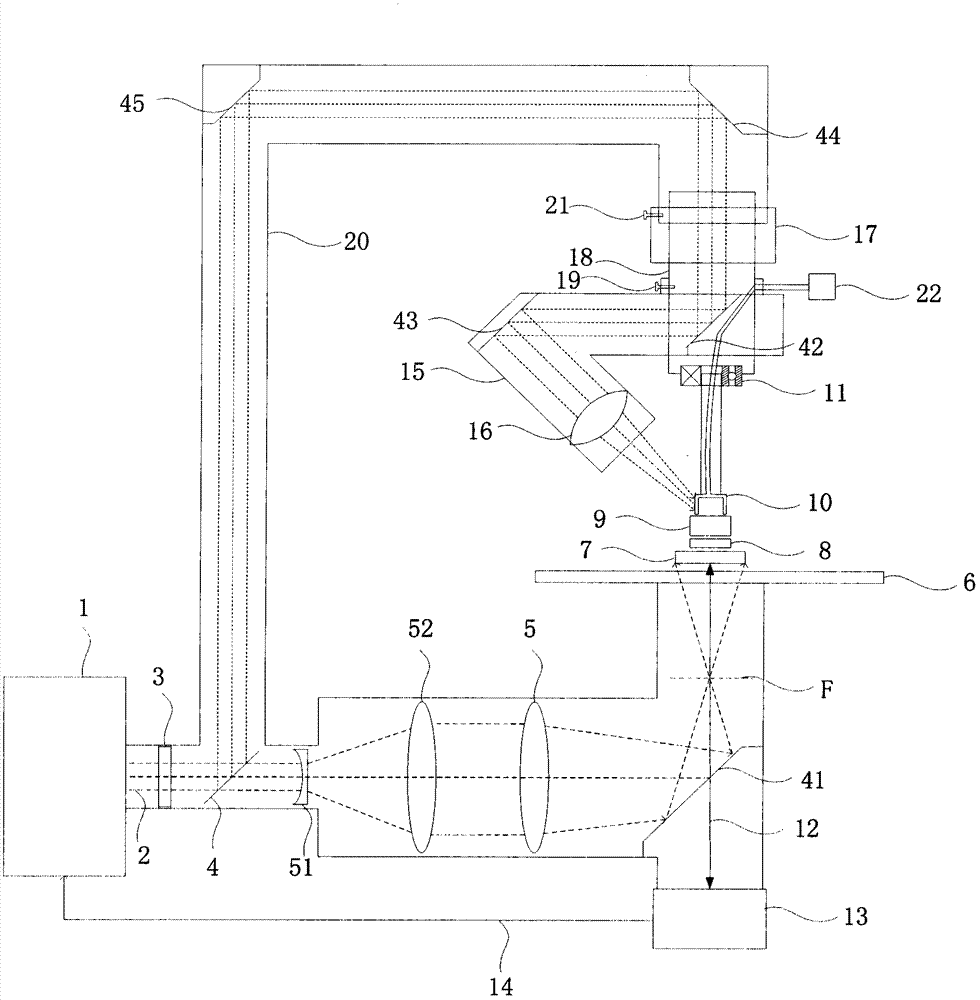

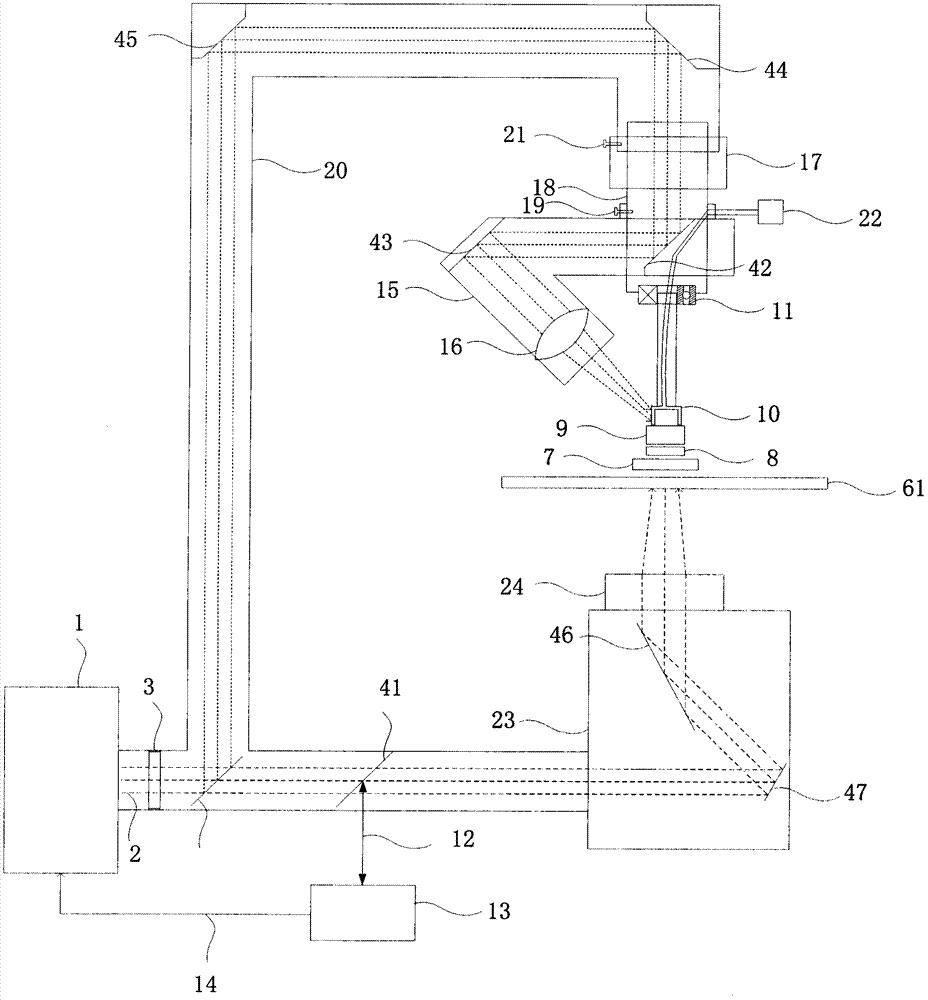

[0060] figure 1 A schematic diagram showing the laser eutectic welding device and method of the present invention. The laser eutectic welding device is composed as follows: laser 1, used to emit laser beam 2; laser beam shaping system 3, to make the laser beam with Gaussian distribution into a flat top beam with uniform energy density distribution; concave lens 51 and convex lens 52 cooperate to realize beam expansion Collimation function, the expanded and collimated laser beam is incident on the laser focusing mirror 5, and cooperates with the laser beam shaping system 3 to match the size of the laser spot irradiated on the eutectic welding base 7 with the size of the eutectic welding chip ; Under the action of vacuum generator and gas pipe 22, suction nozzle 10 picks up and places eutectic welding solder 8 and eutectic welding chip 9 on eutectic welding base 7, and eutectic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com