Novel method for preparing Co3O4 spiral nanobelt by using three-dimensional porous kenaf stalk carbon as template

A three-dimensional porous, kenaf rod technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of simple operation and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

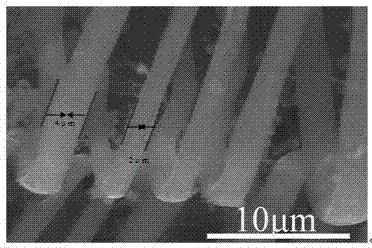

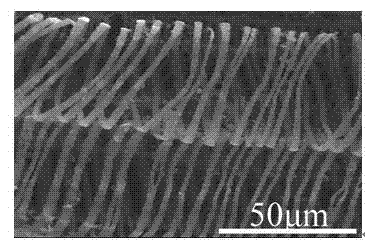

[0010] 0.3 g of kenaf carbon was placed in 1.0 mM Co(NO 3 ) 2 , 2.0 mM NH 4 F and 5.0 mM CO(NH 2 ) 2 in the mixed solution, stirred for 10 min, put the obtained solution and kenaf carbon into the reaction kettle, and reacted at 120 °C for 5 h. After cooling to room temperature and cleaning with water, put it into a tubular atmosphere furnace under the protection of nitrogen and raise the temperature to 400 °C at 1 °C / min and maintain it for 4 h. You can get Co 3 o 4 Helical nanoribbons.

Embodiment 2

[0012] 0.6 g of kenaf stalks were placed in 2.0 mM Co(NO 3 ) 2 , 4.0 mM NH 4 F and 10.0 mM CO(NH 2 ) 2 in the mixed solution, stirred for 10 min, put the obtained solution and kenaf carbon into the reaction kettle, and reacted at 120 °C for 5 h. After cooling to room temperature and cleaning with water, put it into a tubular atmosphere furnace under the protection of nitrogen and raise the temperature to 300 °C at 1 °C / min and maintain it for 4 h. You can get Co 3 o 4 Helical nanoribbons.

Embodiment 3

[0014] 0.3 g of kenaf stalks were placed in 1.0 mM Co(NO 3 ) 2 , 2.0 mM NH 4 F and 5.0 mM CO(NH 2 ) 2 The mixed solution was stirred for 10 min, and the obtained solution and kenaf carbon were put into a reaction kettle and reacted at 120 °C for 5 h under the protection of nitrogen. After cooling to room temperature and cleaning with water, put it into a tube-type atmosphere furnace and raise the temperature to 500 °C at 1 °C / min in nitrogen and maintain it for 4 h. You can get Co 3 o 4 Helical nanoribbons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com