Morchella cultivation formulation and preparation method therefor

A technique for cultivation and formula of Morchella, applied in directions such as the preparation of organic fertilizers, organic fertilizers, and fertilizer mixtures, and can solve problems such as difficulty in meeting market demands, poor quality of Morchella, and poor cultivation effect of Morchella nutrient formula. and other problems to achieve the effect of improving quality, increasing nutrient absorption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

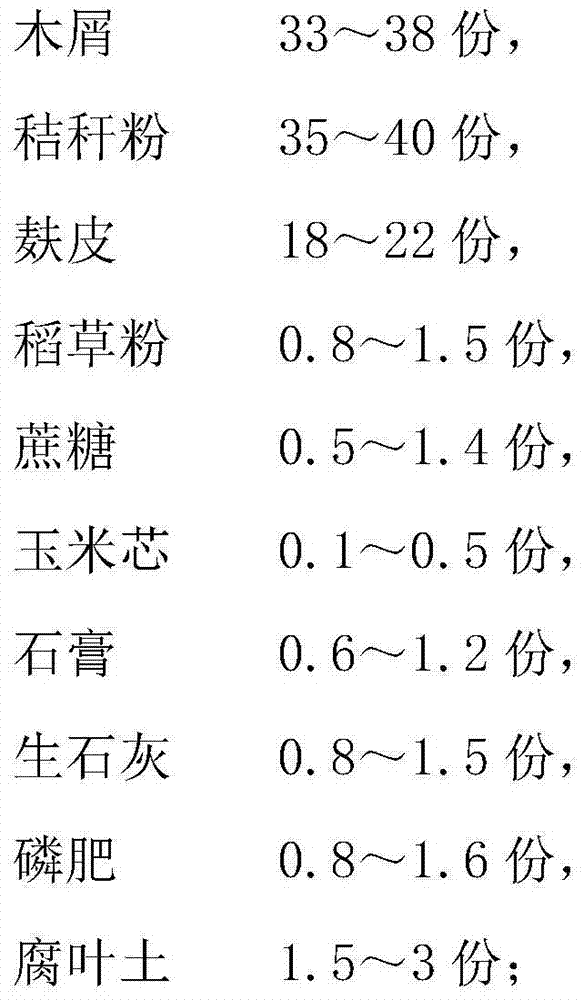

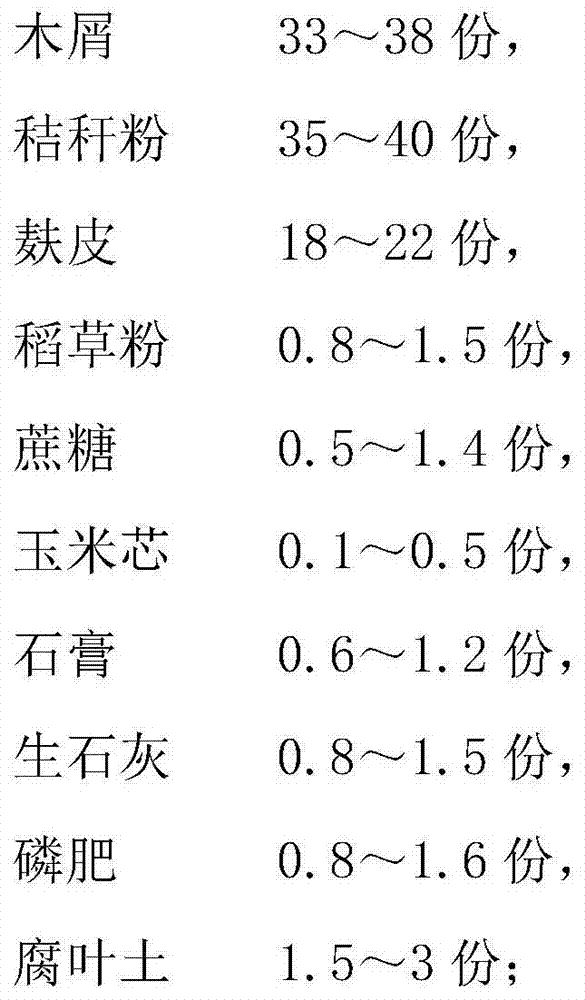

Embodiment 1

[0030] A morel cultivar formula, which consists of: 34 parts of broad-leaved plant sawdust, 38 parts of corn stalk powder, 18 parts of bran, 0.9 part of rice straw powder, 1.4 parts of sucrose, 0.4 part of corncob in parts by weight, 0.6 parts of gypsum, 0.9 parts of quicklime, 0.8 parts of potassium dihydrogen phosphate, and 3 parts of leaf humus; the ratio of material to water for the morel cultivar formula is 1:1.4.

[0031] The steps of its preparation method are as follows:

[0032] (1) Add corn stalks and rice straw to a pulverizer to grind them into corn stalk powder and rice straw powder, add corn stalk powder, rice straw powder, broad-leaved plant sawdust, and corncobs to a ball mill for 2 hours to obtain a powder with a particle size of 0.5mm Powder;

[0033] (2) Crush the potassium dihydrogen phosphate and sieve it, dissolve it in water and let it stand for 10 hours, take out the supernatant and filter it, stir the quicklime, gypsum, bran and sucrose evenly, and ad...

Embodiment 2

[0037] A morel cultivar formula, which consists of: 36 parts of round-leaf plant sawdust, 40 parts of rice straw powder, 20 parts of bran, 1.0 part of rice straw powder, 1.2 parts of sucrose, 0.1 part of corn cob, 0.9 parts of gypsum, 0.8 parts of quicklime, 1.4 parts of potassium dihydrogen phosphate, and 2.5 parts of leaf humus; the ratio of material to water for the morel cultivar formula is 1:1.4.

[0038] The steps of its preparation method are as follows:

[0039] (1) Add rice stalks and straws to a pulverizer and pulverize them into rice stalk powder and rice straw powder, add rice straw powder, rice straw powder, round leaf plant sawdust, and corncobs to a ball mill for 2 hours to obtain a powder with a particle size of 0.5mm Powder;

[0040] (2) Crush the calcium superphosphate and sieve it, dissolve it in water and let it stand for 10 hours, take out the supernatant and filter it, stir the quicklime, gypsum, bran and sucrose evenly, and add the filtered supernatant ...

Embodiment 3

[0044] A morel cultivar formula, which consists of: 35 parts of round leaf plant sawdust, 39 parts of corn stalk powder, 22 parts of bran, 0.8 part of straw powder, 0.5 part of sucrose, 0.3 part of corn cob, 0.8 parts of gypsum, 1.4 parts of quicklime, 1.5 parts of superphosphate, and 1.5 parts of leaf humus; the material-water ratio of the morel cultivar formula is 1:1.4.

[0045] The steps of its preparation method are as follows:

[0046] (1) Add corn stalks and straw to a pulverizer to grind them into corn stalk powder and rice straw powder, add corn stalk powder, rice straw powder, round-leaf plant sawdust, and corn cobs to a ball mill for 2 hours to obtain a powder with a particle size of 0.5mm Powder;

[0047] (2) Crush the potassium dihydrogen phosphate and sieve it, dissolve it in water and let it stand for 10 hours, take out the supernatant and filter it, stir the quicklime, gypsum, bran and sucrose evenly, and add it together with the leaf humus The supernatant wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com