A preparation method of fan impeller inlaid ceramics

A technology for preparing ceramics and a fan, applied in the field of composite wear-resistant materials, can solve the problems such as the inability to withstand high temperature of pasted ceramics, poor wear resistance of thermal spraying, and increased weight of composite panels, and achieves convenient post-repair treatment, easy installation, and convenient fans. The effect of remanufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the specific implementation of the present invention is not limited thereto.

[0044] The purpose of the present invention is that compared with metal materials, ceramic materials have performance advantages such as high hardness, high strength, high temperature resistance, wear resistance, corrosion resistance, and oxidation resistance. Under the impact load of the medium, the ceramic sheet is easy to fall off, which reduces the wear resistance of the fan. A wear-resistant ceramic inlaid on the working surface of the fan impeller and a preparation method thereof are provided, which can solve the above problems and achieve a better use effect.

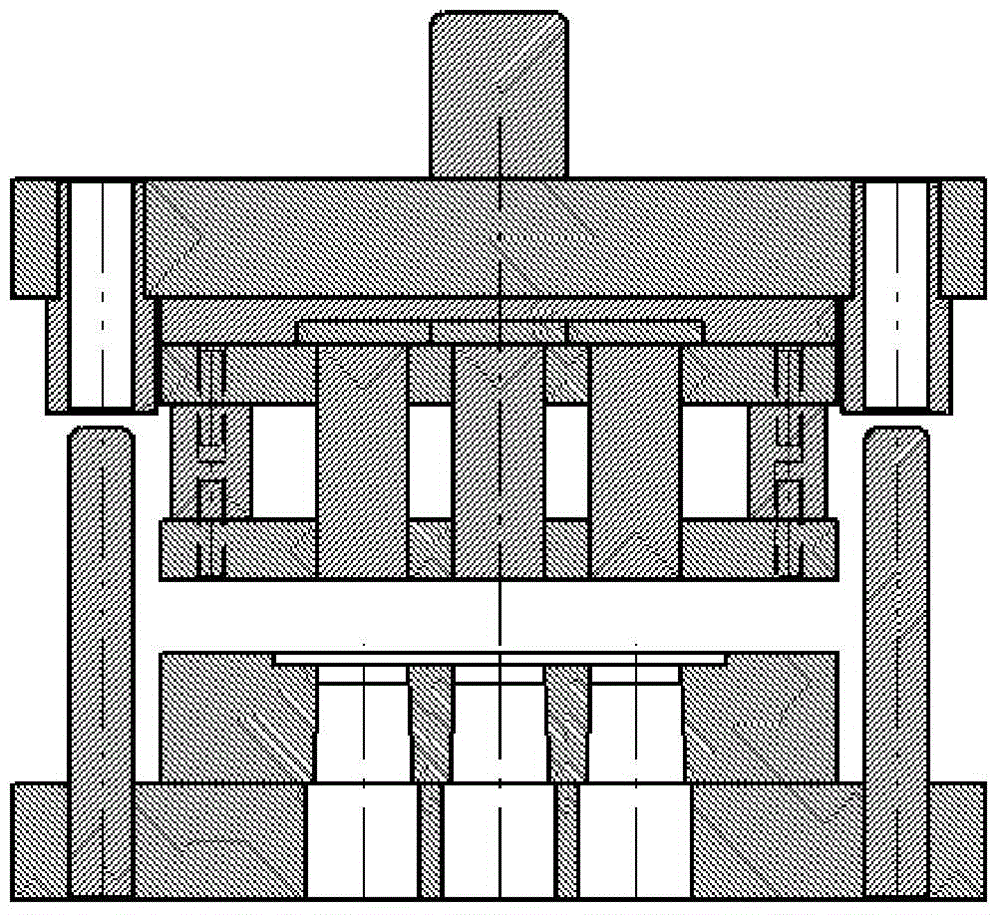

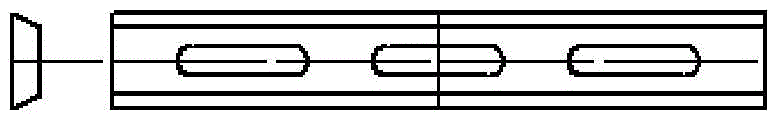

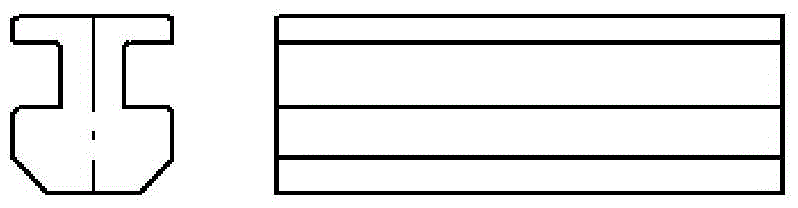

[0045] The invention proposes a specific inlaid ceramic block designed according to the fan structure, and designs an inlaid ceramic steel clip. Through steel clip plug welding, the ceramic block is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com