Modular reconfigurable motion controller architecture based on SERCOS

A motion controller, architecture technology, applied in general control systems, control/regulation systems, digital control, etc., to solve problems such as limitations, reconfigurability, and flexibility limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

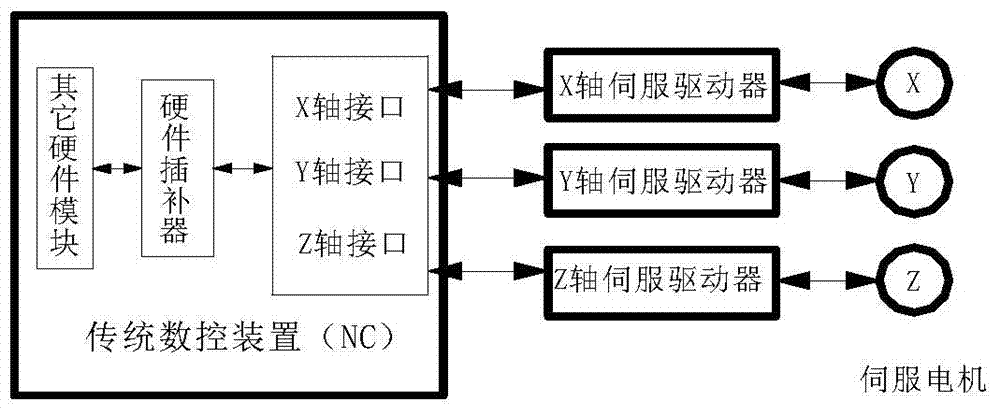

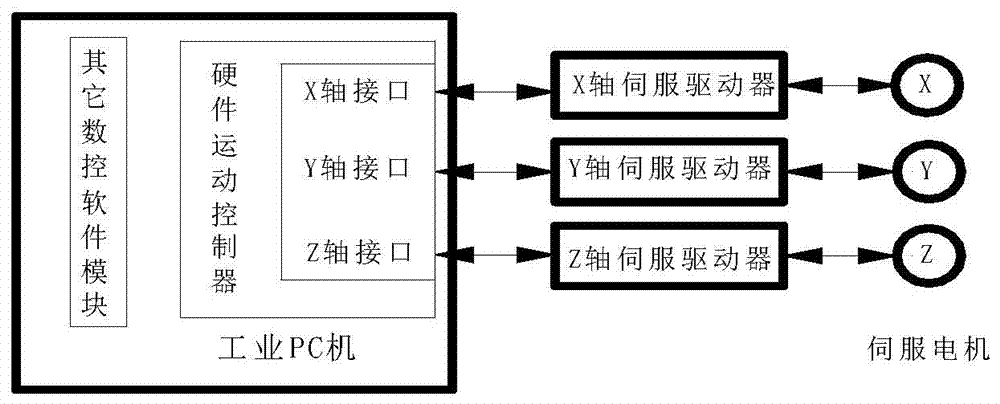

Problems solved by technology

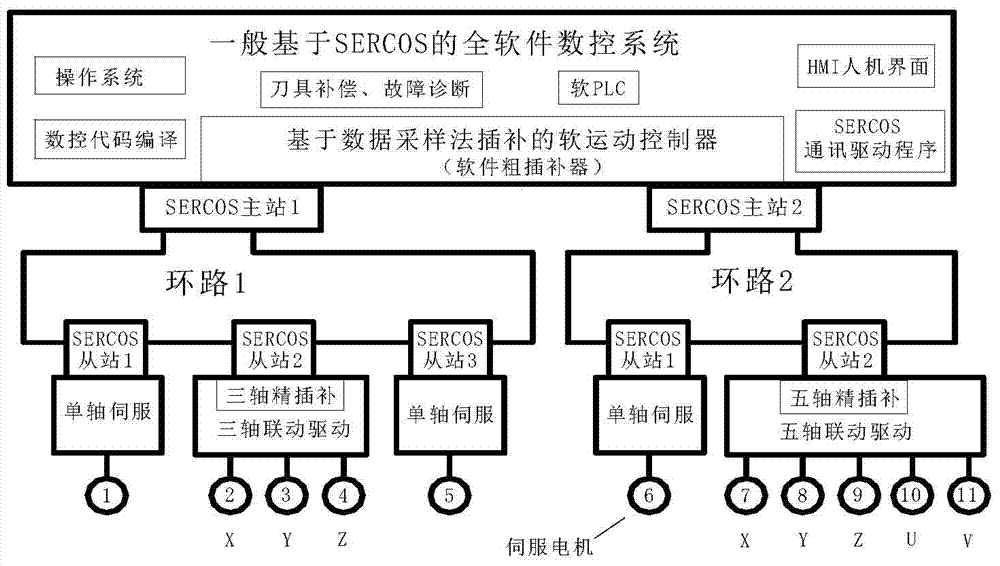

Method used

Image

Examples

Embodiment 1

[0048] A specific embodiment according to the principles of the present invention is attached Figure 7shown. This scheme can be used in distributed CNC production lines. There are often multiple CNC machining centers on this production line, such as three-coordinate milling centers, two-coordinate drilling and tapping centers, two-coordinate turning centers, multi-degree-of-freedom loading and unloading manipulators, multi-degree-of-freedom painting manipulators, etc. The distance between each processing center or manipulator ranges from 3 meters to 20 meters, and the arrangement and processing sequence can also be adjusted at any time according to the needs of different products. In the prior art [1], [3], due to the limitation of hardware servo interface and fixed wiring, arbitrary increase, decrease and adjustment cannot be achieved.

Embodiment 2

[0050] Another specific embodiment according to the principle of the present invention is attached Figure 8 shown. This solution can be used in the "CNC combined machine tool" similar to the traditional combined machine tool, and design the power head, tool holder, servo mechanism and screw, servo mechanism and rack and pinion, servo mechanism and worm gear, servo mechanism and positioning plate mechanism, etc. Into a standard structure that can be disassembled and assembled, according to the needs of processed products, "piece together" a high-efficiency special-purpose CNC machine tool like building blocks. Then by redefining each servo axis and calling the corresponding linkage interpolation software module to realize the specific numerical control function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com