A kind of automatic bonding equipment and assembly process of thermal battery current collector assembly

An automatic bonding and assembly process technology, applied in the direction of delayed action cells, etc., can solve the problems of low bonding precision, low assembly precision, and easy relative displacement, etc., to reduce the number of molds, improve installation accuracy, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

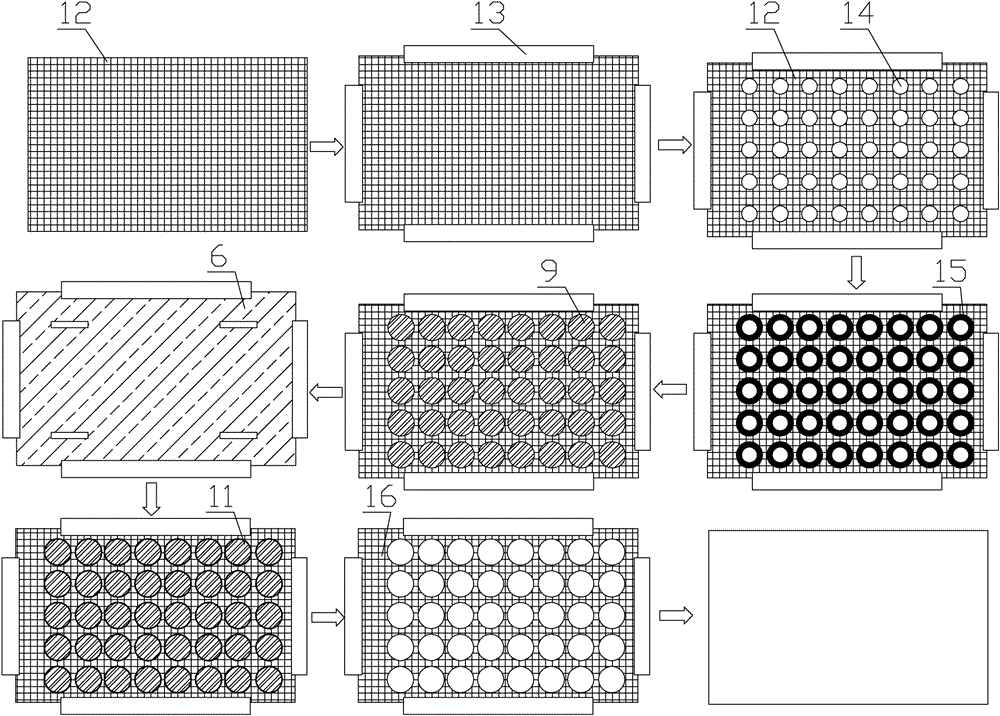

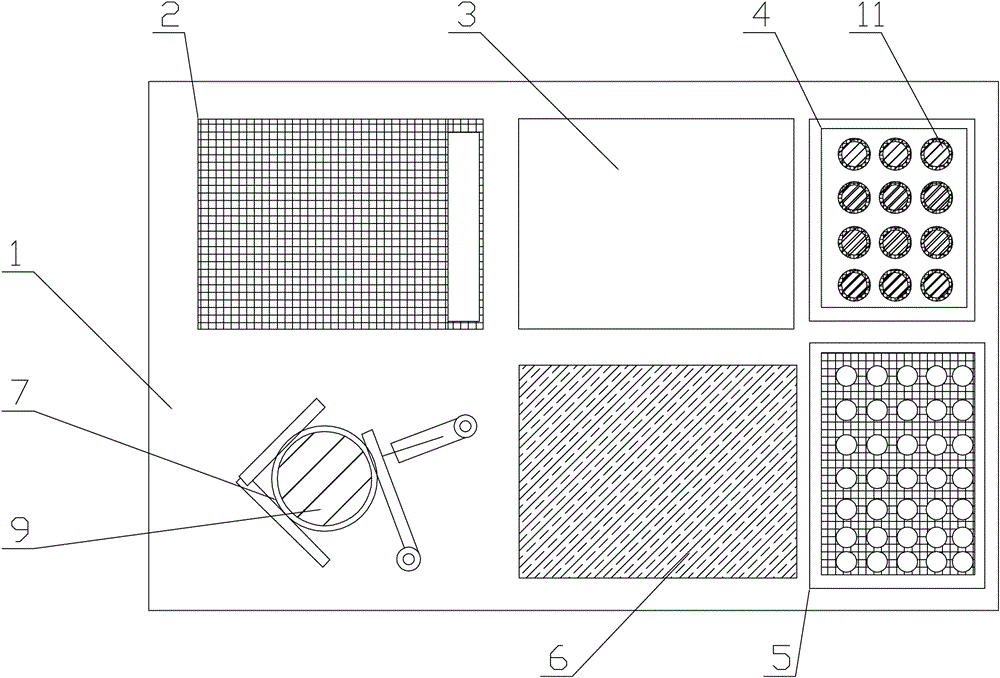

[0029] see figure 1 , is the flow chart of the assembly process of the current collector, which includes nine main steps: the first step, the asbestos paper 12 is automatically picked up and placed. Through the suction device installed on the two-dimensional numerical control platform 1, move to the placement area of the high-temperature asbestos paper box 2 installed on the two-dimensional numerical control platform 1 to absorb the whole asbestos paper 12, and then place it on the two-dimensional numerical control platform 1. Combined with the working area 3, the preheating device of the high-temperature asbestos paper box 2 can preheat the asbestos paper 12, which is beneficial to the subsequent process; the suction device can use a manipulator to drive a vacuum suction cup to absorb the asbestos paper 12.

[0030] In the second step, the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com