High-efficiency holmium laser

A holmium laser, high-efficiency technology, applied in the laser field, can solve problems such as the inability to prevent the condensation of water vapor on the end face of the laser crystal, the reduction of laser reliability, and the limitation of laser efficiency, etc., to improve the speed and uniformity of cooling water flow, improve cooling effect, and improve The effect of laser efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

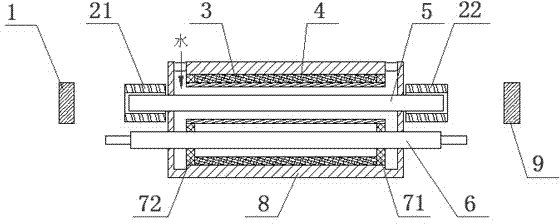

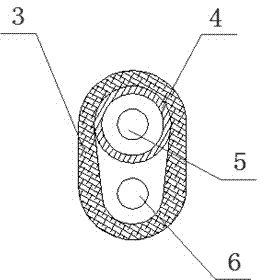

[0027] Such as Figure 1~2 As shown, a high-efficiency holmium laser according to the present invention includes a resonant cavity, a concentrating cavity, a laser crystal rod 5 and a pulsed xenon lamp 6; the concentrating cavity includes a ceramic reflector 3, a cerium-doped quartz sleeve 4, Guide baffles 71, 72, crystal end heating sleeves 21, 22 and cavity structure 8; the light collecting cavity, laser crystal rod 5, and pulsed xenon lamp 6 together form a holmium laser pump cooling module, its structure and characteristics It is: the cerium-doped quartz sleeve 4 is embedded in the ceramic reflector 3, the laser crystal rod 5 passes through the cerium-doped quartz sleeve 4, and the two ends of the laser crystal rod 5 are supported by the cavity structure 8 and realize The inside and outside of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com