Heat-assisted magnetic recording head, semiconductor laser element, and manufacturing method of semiconductor laser element

一种激光元件、半导体的技术,应用在半导体激光器的结构细节、半导体激光器、磁记录头等方向,能够解决半导体激光元件40与浮动块10紧贴性降低、不能充分提升热辅助磁记录头1散热性、发光部52与凹部51体积差较大等问题,达到提升平坦性、防止蚀刻、提升导热性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

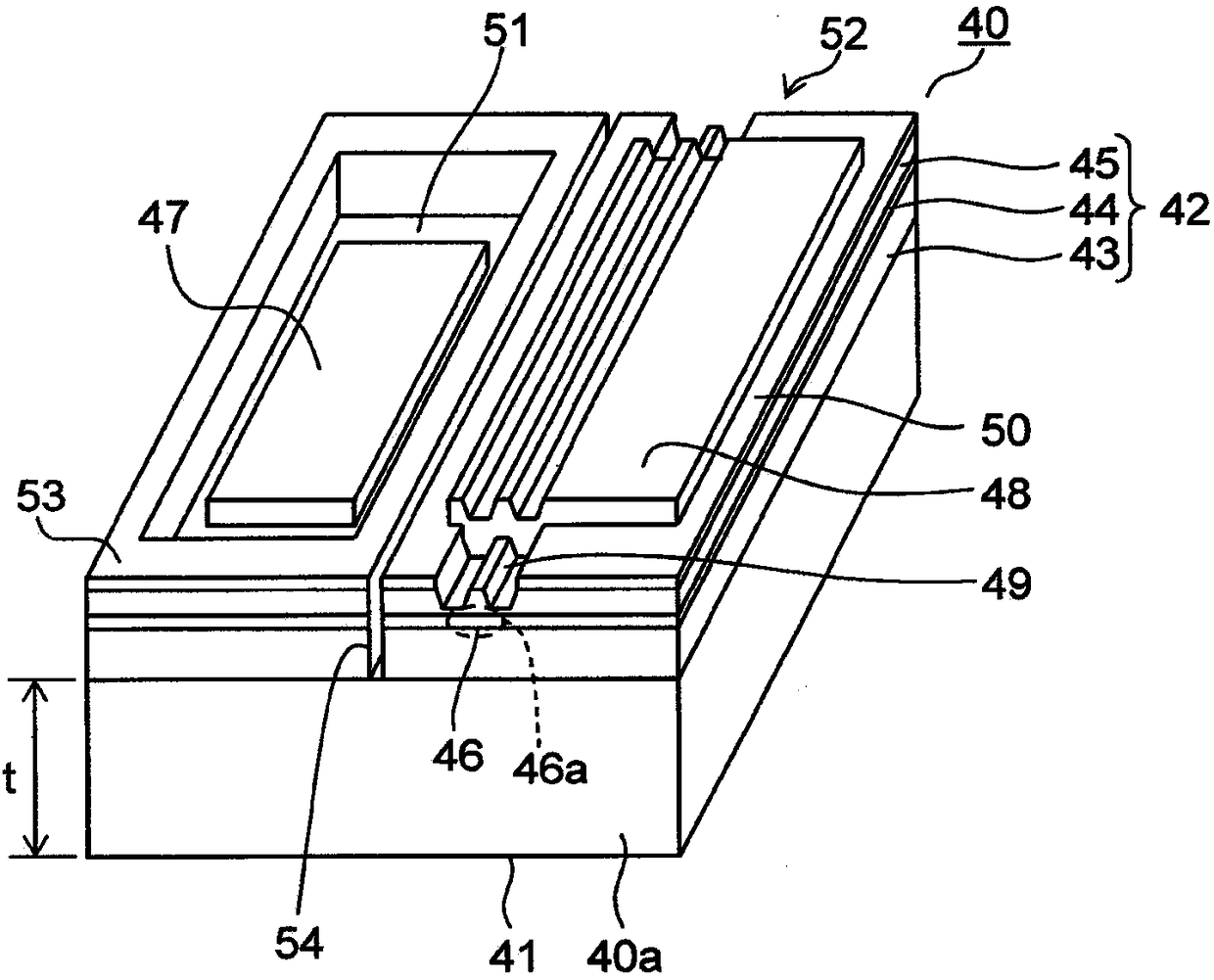

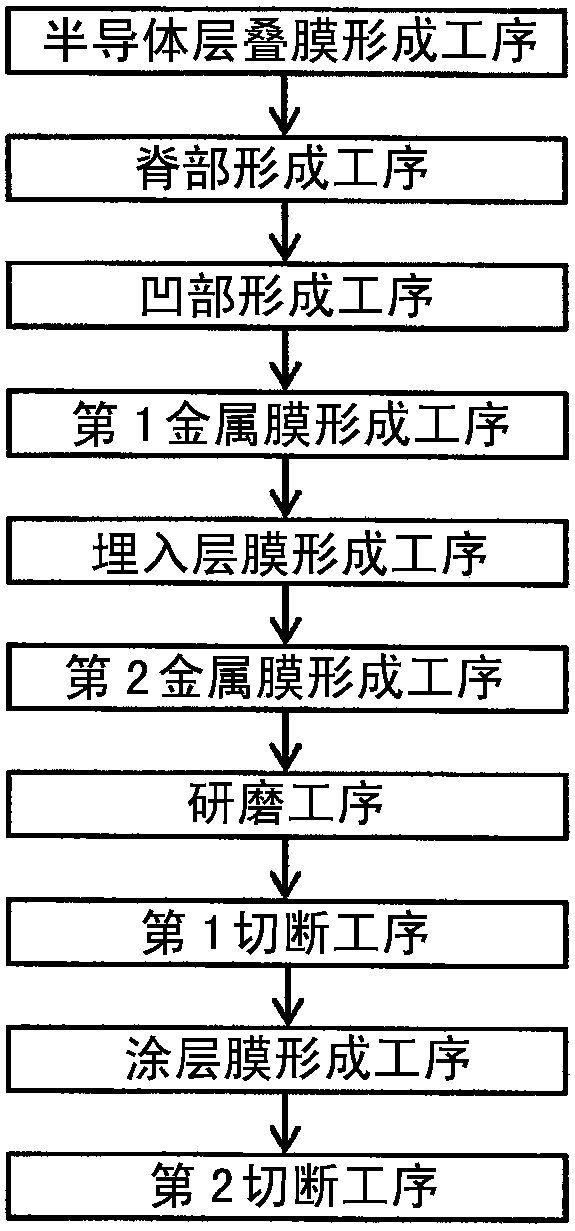

[0061] Embodiments of the present invention are described below with reference to the drawings. For the convenience of explanation, for the aforementioned Figure 12 , Figure 13 In the conventional examples shown, the same parts are denoted by the same reference numerals. figure 1 A front view showing the heat-assisted magnetic recording head of the first embodiment. The heat-assisted magnetic recording head 1 is mounted on an HDD device or the like, and is disposed on a magnetic disk D so as to be axially movable by being supported by a suspension (not shown).

[0062] The heat-assisted magnetic recording head 1 includes: a slider 10 facing a magnetic disk D; and a semiconductor laser element 40 bonded to the slider 10 with a thermally conductive adhesive 19 . The slider 10 floats on the magnetic disk D rotating in the direction of the arrow A, and has a magnetic recording unit 13 and a magnetic reproducing unit 14 at the end on the medium ejection side. The magnetic rec...

no. 2 Embodiment approach

[0102] Next, Figure 10 A perspective view showing a semiconductor laser element 40 of the heat-assisted magnetic recording head 1 according to the second embodiment. For the convenience of explanation, for the aforementioned figure 2 The same parts as those in the first embodiment shown are given the same reference numerals. The shape of the protective wall 53 of the present embodiment is different from that of the first embodiment. Other parts are the same as the first embodiment.

[0103] The protective wall 53 is open in one direction facing the light emitting portion 52 . Even with such a configuration, the same effect as that of the first embodiment can be obtained. At this time, the separation groove 54 is formed so as not to overlap with the first electrode 47 projected on the emission surface 40a. This prevents adhesive 19 (refer to figure 1 ) Attachment to the first electrode 47.

no. 3 Embodiment approach

[0105] Next, Figure 11 A perspective view showing a semiconductor laser element 40 of the heat-assisted magnetic recording head 1 according to the third embodiment. For the convenience of explanation, for the aforementioned figure 2 The same parts as those in the first embodiment shown are given the same reference numerals. The shape of the protective wall 53 of the present embodiment is different from that of the first embodiment. Other parts are the same as the first embodiment.

[0106] The protective wall 53 is divided by the groove part 53a at several positions in the circumferential direction. Even with such a configuration, the same effect as that of the first embodiment can be obtained. At this time, the groove portion 53a on the emission surface 40a is arranged so as not to overlap with the first electrode 47 projected on the emission surface 40a. This prevents adhesive 19 (refer to figure 1 ) Attachment to the first electrode 47. In addition, the groove par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com