Method for increasing yield of antrodia cinnamomea and bioactive substance content of antrodia cinnamomea

A bioactive substance, Antrodia camphorata technology, applied in the directions of botanical equipment and methods, plant cultivation, bulk chemical production, etc., can solve the problems of long cultivation time, high cost, and difficulty in obtaining Antrodia camphorata basswood, etc., to slow down the growth rate. and the formation of biologically active substances, the effect of increasing yield and accelerating growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

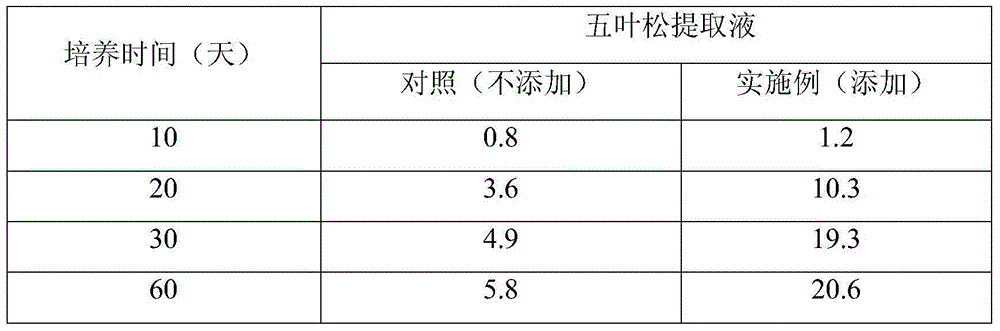

Embodiment 1

[0044] A method for increasing the yield of Antrodia camphorata and the content of biologically active substances thereof, comprising the following steps:

[0045] 1) Prepare the five-leaved pine extract:

[0046] The roots, stems, and leaves of Pinus chinensis are crushed to a particle size of 35-60 μm at a low temperature of 5°C under vacuum conditions, mixed evenly, dissolved in 20% alcohol, and subjected to ultrasonic crushing to destroy the cell walls and dissolve the resin of Pinus pinus vinifera. The ultrasonic crushing conditions are temperature 25°C, time 25min; after ultrasonic crushing, supercritical fluid extraction is performed to extract pine resin. Obtain the five leaf pine extracts with different pH;

[0047] Wherein, when the ratio of root:stem:leaf is 93:6:1, a five-leaf pine extract with pH=5.5 is obtained;

[0048] When the ratio of root:stem:leaf is 50:35:15, a five-leaf pine extract with pH=6.0 is obtained;

[0049] When the ratio of root:stem:leaf is 40...

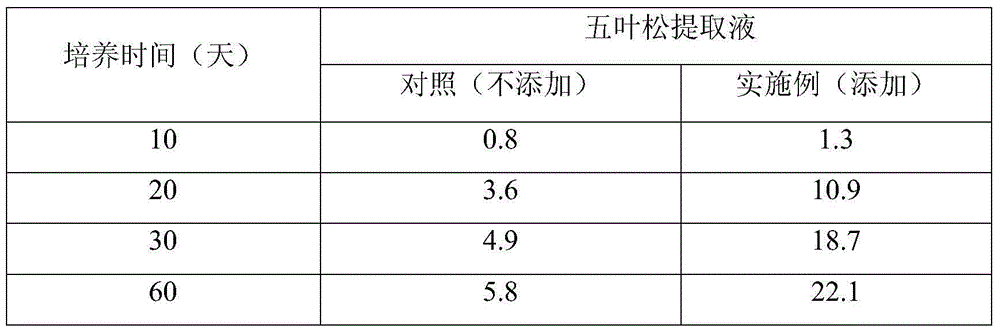

Embodiment 2

[0065] A method for increasing the yield of Antrodia camphorata and the content of biologically active substances thereof, comprising the following steps:

[0066] 1) Prepare the five-leaved pine extract:

[0067] The roots, stems and leaves of Pinus chinensis are crushed at a low temperature of 10°C under vacuum conditions to a particle size of 35-60 μm, mixed evenly, dissolved in 20% alcohol for ultrasonic crushing, and the cell walls are destroyed to dissolve the resin of the five-leaved pine. The ultrasonic crushing conditions are temperature 30°C, time 20min; after ultrasonic crushing, supercritical fluid extraction is performed to extract pine resin. Obtain the five leaf pine extracts with different pH;

[0068] Wherein, when the ratio of root:stem:leaf is 95:4:1, a five-leaf pine extract with pH=5.5 is obtained;

[0069] When the ratio of root:stem:leaf is 45:40:15, a five-leaf pine extract with pH=6.0 is obtained;

[0070] When the ratio of root:stem:leaf is 38:32:3...

Embodiment 3

[0085] A method for increasing the yield of Antrodia camphorata and the content of biologically active substances thereof, comprising the following steps:

[0086] 1) Prepare the five-leaved pine extract:

[0087] The roots, stems and leaves of Pinus chinensis are crushed at a low temperature of 8°C under vacuum conditions to a particle size of 35-60 μm, mixed evenly, dissolved in 20% alcohol for ultrasonic crushing, and the cell walls are destroyed to dissolve the resin of the five-leaved pine. The ultrasonic crushing condition is temperature 28°C, time 20min; after ultrasonic crushing, supercritical fluid extraction is performed to extract pine resin. Obtain the five leaf pine extracts with different pH;

[0088] Wherein, when the ratio of root:stem:leaf is 95:4:1, a five-leaf pine extract with pH=5.5 is obtained;

[0089] When the ratio of root:stem:leaf is 50:35:15, a five-leaf pine extract with pH=6.0 is obtained;

[0090] When the ratio of root:stem:leaf is 40:30:30, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com