Abelmoschus esculentus fruit freezing vacuum drying method

A technology of freeze-vacuum drying and vacuum freeze-drying, which is applied in the field of okra freeze-vacuum drying technology, can solve the problems of high energy consumption and food production costs, few professional and technical personnel, and lagging behind in basic theoretical research. Complete dehydration and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

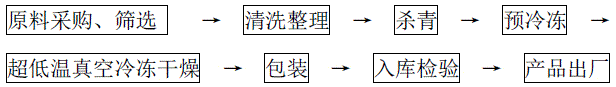

[0023] Please refer to figure 1 , the present embodiment, okra freeze-vacuum drying process, comprising: screening excellent fresh okra from the purchased okra raw materials, cleaning and finishing in a cleaning tank; putting the cleaned fresh okra into a de-enzyming kettle for de-enzyming; Put the green okra into the freezer for pre-freezing, the pre-freezing temperature is -35°C, and the time is 2.5 hours, and store it for later use; put the pre-frozen okra into a freeze-vacuum dryer, and perform ultra-low temperature vacuum freeze-drying to obtain crisp okra fruit Finished product: put the finished okra brittle fruit into a packaging machine for packaging, put it in storage, and inspect it through inspection equipment, and the qualified product will leave the factory.

[0024] In the ultra-low temperature vacuum freeze-drying process, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com