Manufacturing method of optical microstructure, machine table and light guide plate of machine table

A technology of optical microstructure and manufacturing method, which is applied in the direction of optics, light guides, optical components, etc., can solve the problems of long processing time, prolonged processing time, and uneven distribution of protrusions, etc., to achieve the best smoothing effect and improve Productivity and the effect of shortening the time required for processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

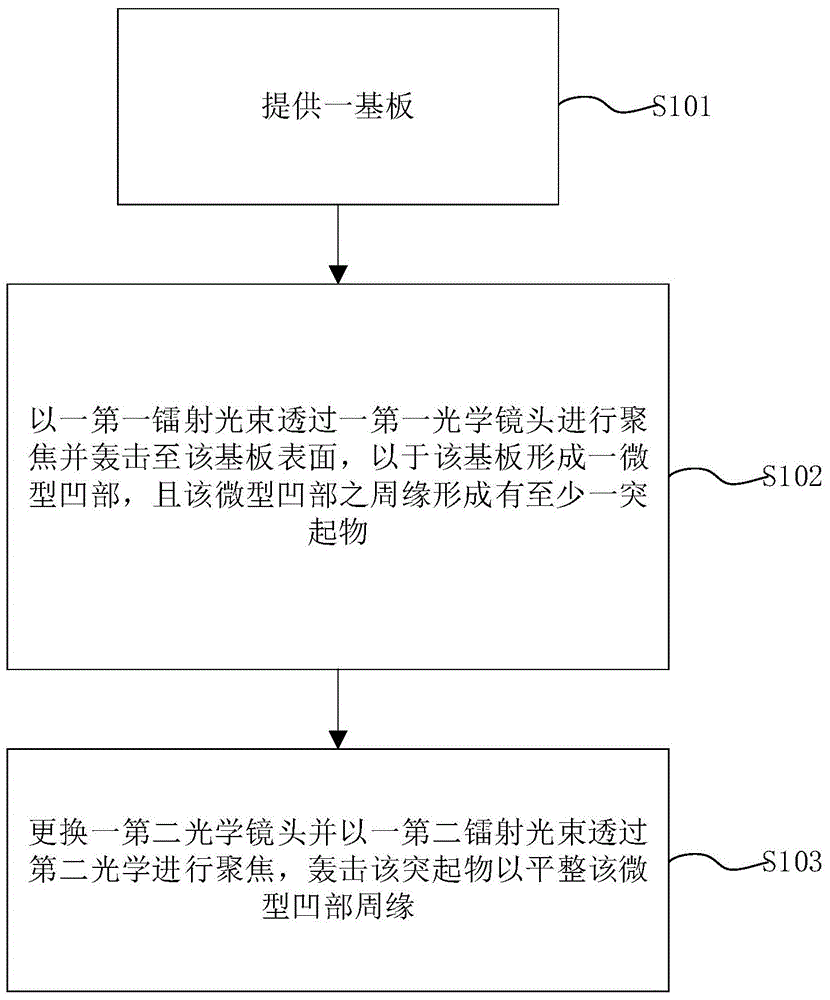

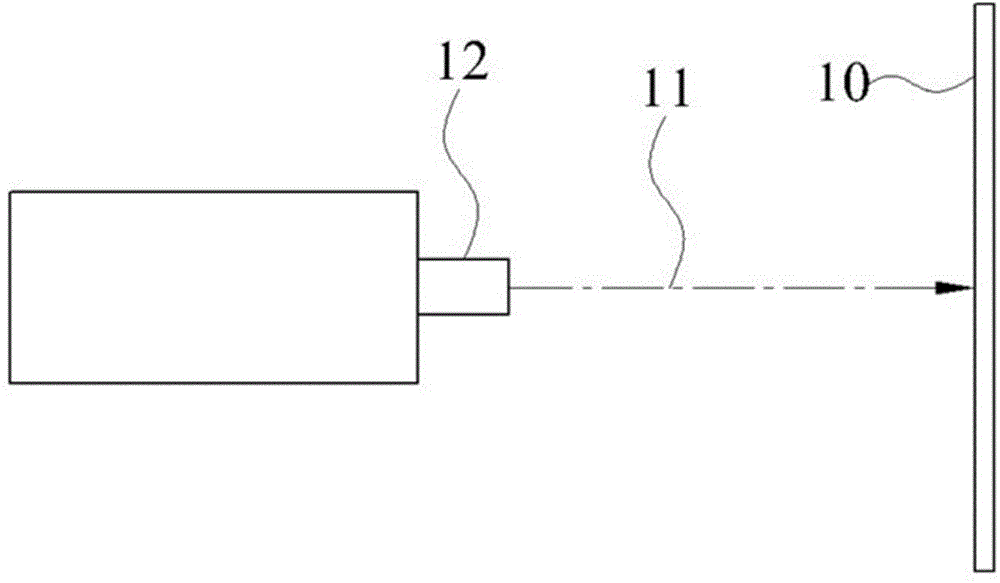

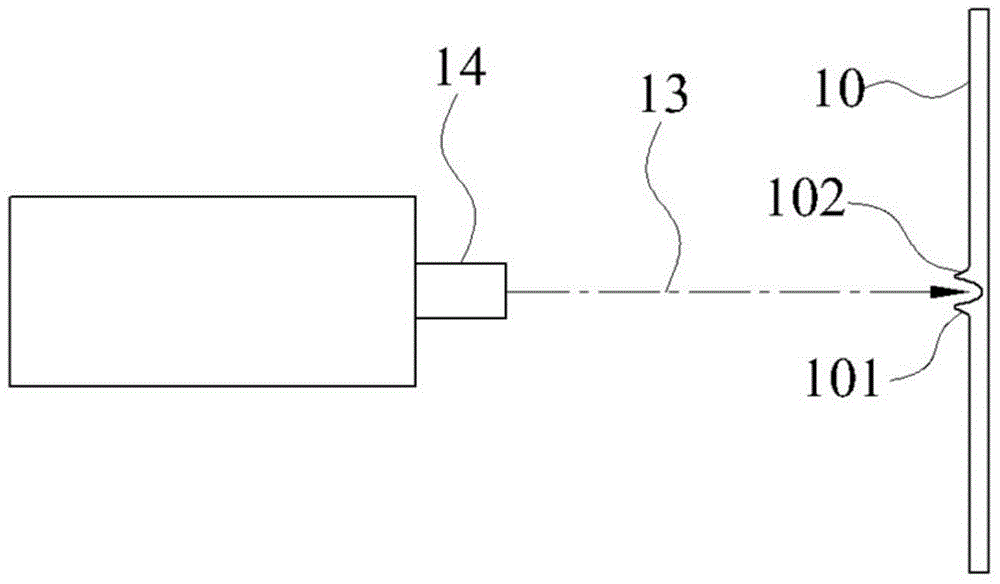

[0074] Please refer to figure 1 and Figure 2A , Figure 2B , which is the method step chart and processing schematic diagram of Experimental Example 1 of the present invention. In view of the deficiencies in the known methods of using lasers to manufacture optical structures for light guide plates, the inventors have carried out many experiments in the field of laser processing to obtain an optimal method for processing optical microstructures through lasers, in order to effectively solve these deficiencies and improve processing efficiency. best way. Experimental Example 1 of the present inventors will be described below.

[0075] Common laser beam output uses electromagnetic waves to pass through the gain medium to adjust the characteristics of the output laser beam. And the gain medium can be sealed in the optical resonant cavity, so as to further make the electromagnetic wave resonate in the optical resonant cavity, so that the electromagnetic wave continuously passes...

experiment example 2

[0079] In view of the shortcomings still in Experimental Example 1, the inventor conceived another processing method, which is as described in Experimental Example 2 below. Please refer to image 3 and Figure 4 , which is a schematic diagram of the method steps and the processing state and micro-holes of Experimental Example 2 of the present invention. A method for manufacturing an optical microstructure is proposed in Experimental Example 2, the steps of which are: step S201, providing a substrate 20; step S202, and irradiating a first laser beam 21 with concentric circular transverse mode images to the substrate 20, A micro recess 201 and a recess 202 are formed on the substrate 20 , and the recess 202 is located around the micro recess 201 .

[0080] Such as Figure 4 As shown, it is the state of the micro-depression 201 and the depression 202 formed on the substrate 20 after the first laser beam bombards the image of the concentric transverse mode. As shown in the fig...

Embodiment 1

[0082] Therefore, after multiple adjustments and experiments, the inventor has further derived the optical microstructure manufacturing method of the multi-mode laser processing machine disclosed by the present invention. Please refer to Figure 5 , 6 , 7A~7C, 8 and Figure 9-10 , which is the method step diagram of Embodiment 1 of the present invention, the schematic diagram of the transverse mode image of the first laser beam, the schematic diagram of the transverse mode image of each second laser beam, the schematic diagram of the transverse mode state after the first laser beam and the second laser beam overlap, and Schematic diagram of each laser processed substrate. The optical microstructure manufacturing method of the multi-mode laser processing machine includes the following steps.

[0083] Step S301 , providing a substrate 30 , wherein the substrate 30 can be a metal mold or a light guide plate.

[0084] Step S302 , irradiating a first laser beam 31 and a second l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com